Pi Mobile IPS (In-process System)

Overview

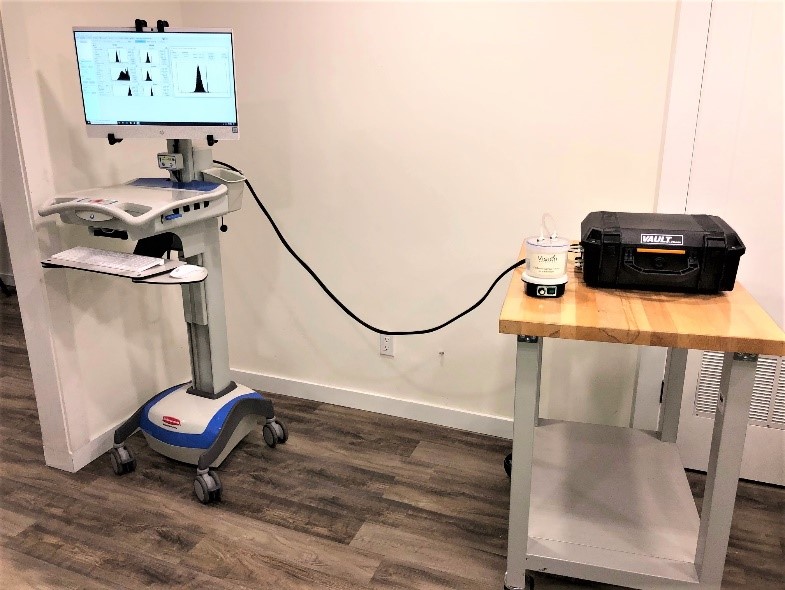

The Pi Mobile In-Process system is a state-of-the-art dynamic image analyzer incorporated into an Analysis Module controlled by a portable battery-operated control unit on a tether.

This system is perfect for applications where monitoring not just the diameter, but the shape of raw materials is vital for on-line processes. Ensuring the same morphology is crucial to ensure the efficacy of the final product in a number of crystallization processes.

It is vital to utilize a high-resolution analytical tool that can supply as much information as possible about raw materials such as crystals being formed over time. The Pi Mobile IPS has been designed to work where raw material manufacturing processes require real-time feedback to make critical process decisions.

It is able to draw a sealed sample from a reactor or process for direct analysis and can return the measured sample back into the process, or to waste. Without interruption, the analysis of the raw material is carried out “on-line”, next to the reactor or process. As it is portable in nature, the Analysis Module can be easily disconnected from one process and reconnected to another without any disruption or substantial modification of customer resources. To ensure minimal dead-volume of sample, the analysis module is connected via a tether allowing it to be close to the process while the control unit can be out of the way offering the user unobstructed access to the process.

The system is driven by a powerful battery with an intelligent charger/controller to keep the battery fully charged all the time. Therefore, an un-interrupted duty cycle of 24/7/365 is expected.

The performance of the instrument is controlled by a Touchscreen All-in-One computer to monitor the analysis of the raw materials.

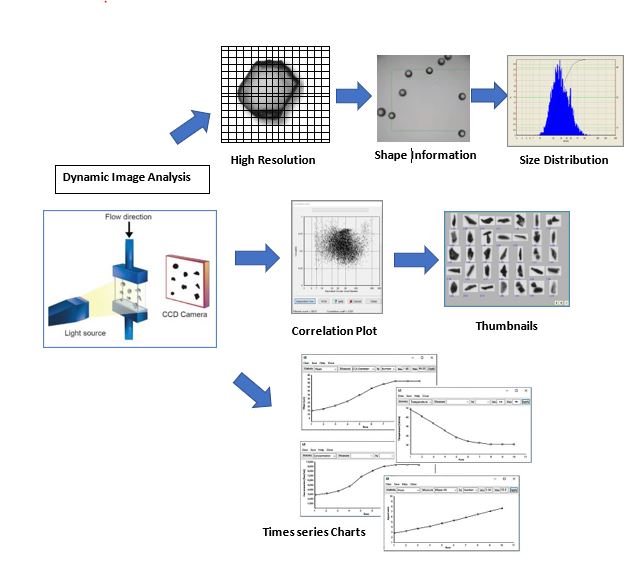

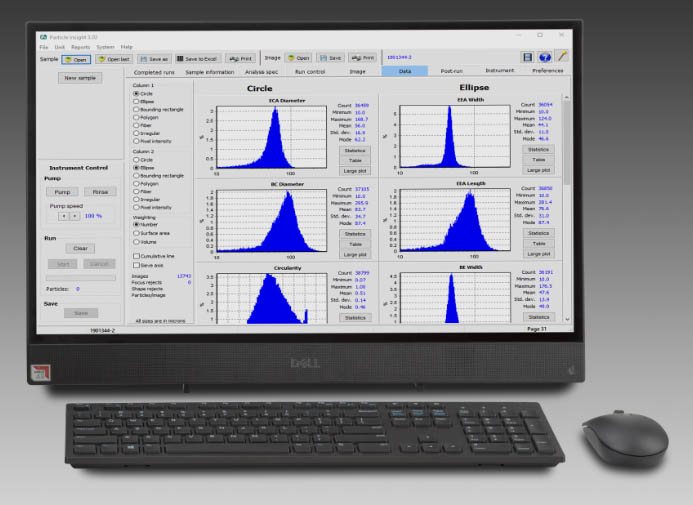

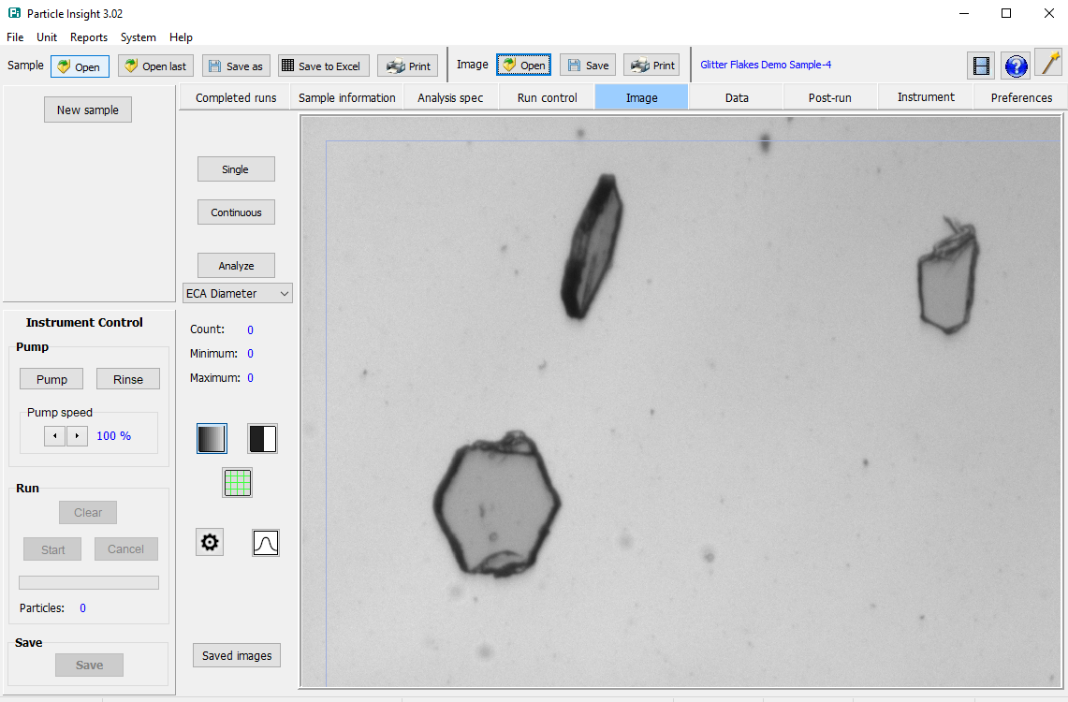

Dynamic Image Analysis

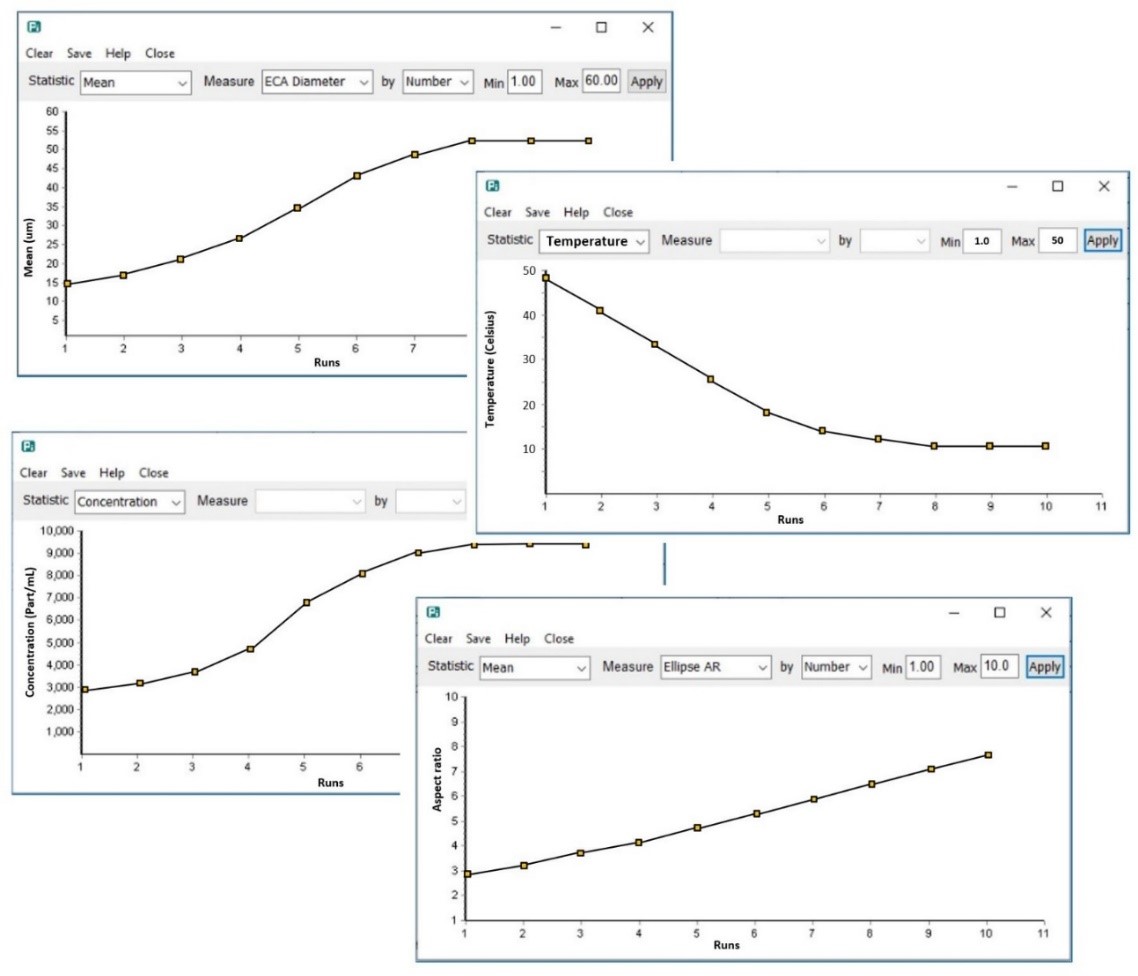

With new techniques coming into the market, industry has come to understand the value of Dynamic Image Analysis. Not only does Dynamic Image Analysis give high resolution traditional size information, it also gives extensive shape information. This added feature, along with images of all measured particles, allows end users to have high resolution process change information as well as the ability to differentiate different populations in a sample, such as what percentage of an Active Pharmaceutical Ingredient (API) vs what percentage of excipient is in a sample. Dynamic Image analysis has also been adapted to an on-line process tool and allows to see real-time process changes and track parameters over time such as size, aspect ratio, concentration, temperature changes and other measurements as they happen, using the Time Series Chart feature.

Pi Mobile IPS New Features

As a new generation of the traditional Particle Insight instrument, the new features are:

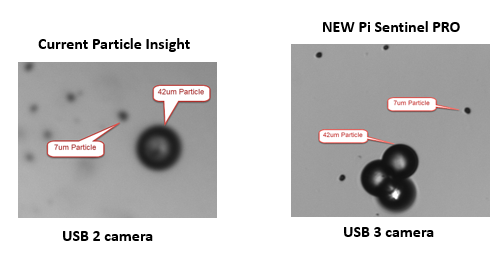

- Improved optics. All components related to image capture (camera and Lens) have been noticeably improved, including easier magnification configuration. Higher speed data transfer rate improves real-time analysis.

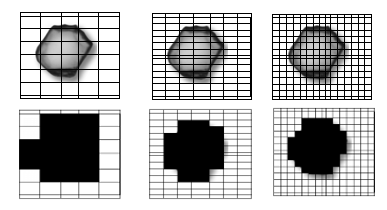

- Improved images. Higher resolution and image capture for better edge definition.

- Improved accuracy. Better accuracy and ability to differentiate minor differences in particle shape down to one micron.

- Improved resolution. High resolution digital camera with up to 5 MPs resolution and higher speed data transfer rate and capable of taking up to 127 frames per second rated, captures live images of thousands of particles.

- Improved fluidics. New fluidic design to improve sample suspension and organic solvent compatibility and reliability.

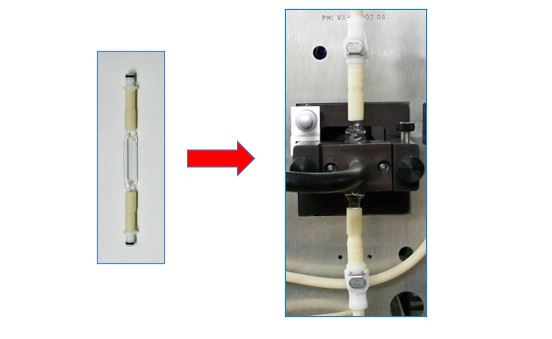

- Improved Sample Cell assembly. The Quartz sample cell has been implemented with quick connectors (body and insert) to facilitate easy removal for cleaning purposes or replacement.

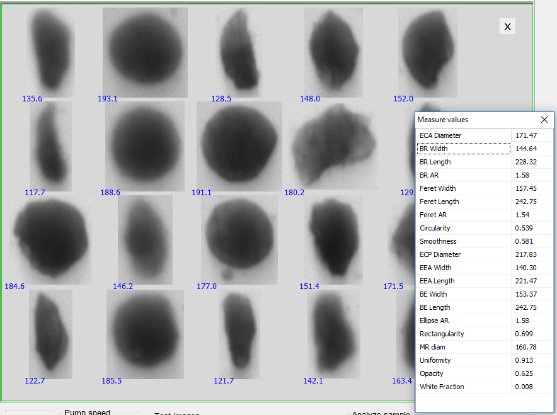

- Improved thumbnail features. When viewing particle thumbnails, the left-mouse button will display all the shape measurement values for that selected thumbnail, the right-mouse button will allow the user to eliminate that specific particle from the database and statistics. Useful when, for example, a single air bubble is not wanted in the database.

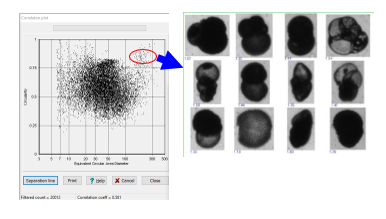

- Improved correlation plot features. Correlation Plot now, able to view thumbnails directly from correlation plot area of interest.

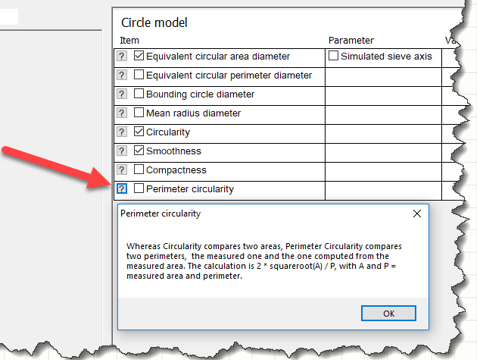

- New perimeter measure. A second Circularity measure was developed called “Perimeter Circularity” to assist customers with existing FPIA systems who have data using this different Circularity measure.

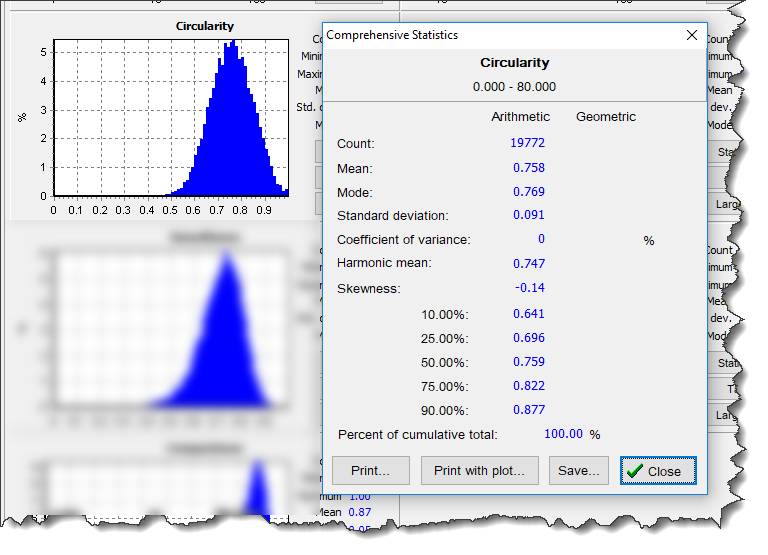

- New 3 digits resolution. Circularity and ALL other fraction measures have data reported with 3-decimal place accuracy. A requirement for transition from FPIA data to Pi Sentinel PRO data.

- New flexible connectivity. This makes possible the connection of the system to a reactor or a standard manufacturing process via tethering connection.

- New instrument Certification program. A Qualification Program using NIST traceable samples is available to certify the system annually and contains all the data required and paperwork to be ready for FDA audits for compliance with 21CFR Part 11 as well as Data Integrity guidelines.

- New Data Integrity compliance. The Certification program complies to new Data Integrity FDA Guidance document.

- New computing platform. Included with every system is a Touchscreen All-in -One computer with wireless keyboard and mouse to allow the customer more interaction with the software features.

- Notification to initiate an additional process. As critical shape parameters are met, the Pi IPS can provide an alarm signal or notification to initiate a separate required process.

- The reactor operation is not interrupted. Keep in mind, being an on-line system, detachment of the Pi IPS module does not disrupt the process, unlike other probe-based methods. This means that the reactor and its contents will not be compromised by the measurement module.

- New software interface. . The software user interface has been changed to reduce the clutter of options presented to the user. The user still has all the options of the old Pi, they are just accessed differently.

- New Time series chart feature. . This feature allows the evaluation of behavior from particles suspended in a solution by plotting results of pre-selected measures and statistics from a collection of run files, over a period of time under the same conditions and settings. The charts created for each combination of parameters reflect the behavior of particles and can be used in different application and processes like dissolution and crystallization in pharmaceutical industries.

Benefits of the Pi Mobile IPS:

As a result of the improvements, the benefits are:

- Higher speed data transfer rate, up to 127 frames per second rated digital camera with up to 5 MPs resolution, captures live images of thousands of particles.

- Over 30 shape parameters are recorded, including circularity, ellipticity, opacity, mean diameter, smoothness, aspect ratio, fiber length and many more

- All analyzed particles have thumbnail images saved for post-run viewing and shape analysis, both in grey scale and binary views.

- Ability to compare different analyses via histogram overlays for all analyzed shape parameters.

- Scatter plot correlates two shape measurements and can be utilized as a process quality control criterion as an at-line application within unit operations.

- Unique and powerful software permits the use to simplify data processing to a pass/fail reporting or choose to extend data analysis to a full suite of post processing image and shape analysis reports

Allows the evaluation of behavior from particles suspended in a solution by plotting results of pre-selected measures and statistics from a collection of run files, over a period of time under same settings.