Pi Sentinel PRO Shape Module

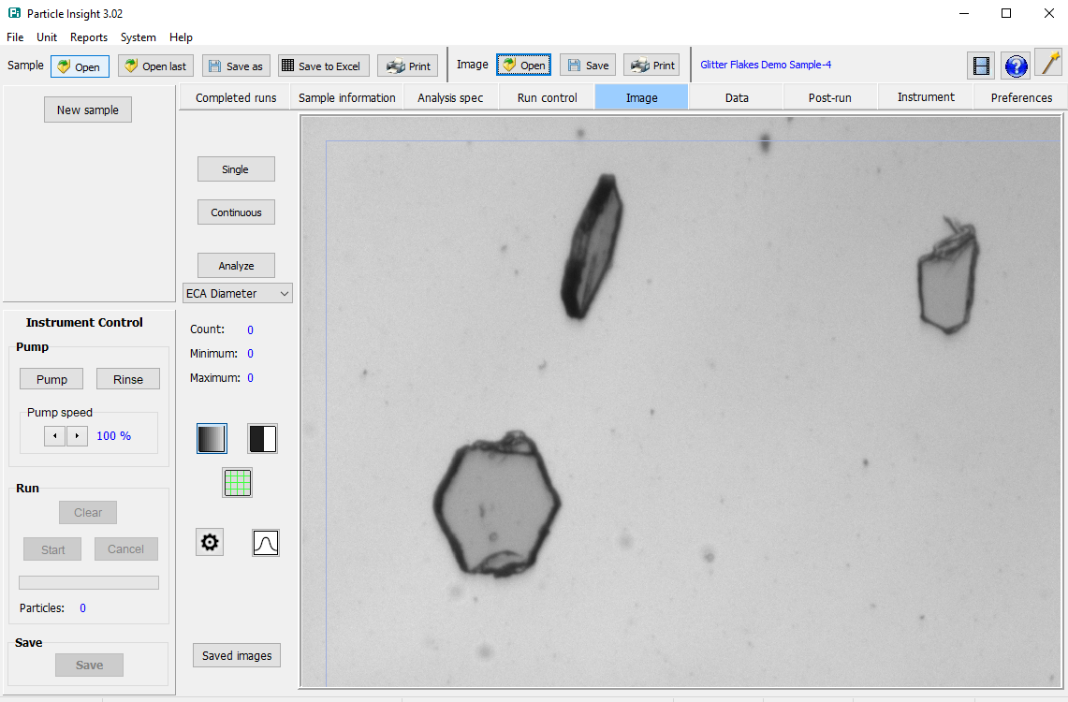

The Pi Sentinel PRO Shape Module (Pi SM) adds comprehensive particle shape analysis capability to laser diffraction and other size-only wet suspension technologies. Rather than determining only particle size information, the Pi SM will report up to 30 different shape-related measures, including size, as well as images of each sample measured.

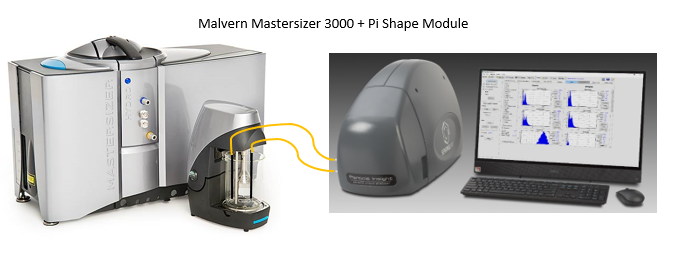

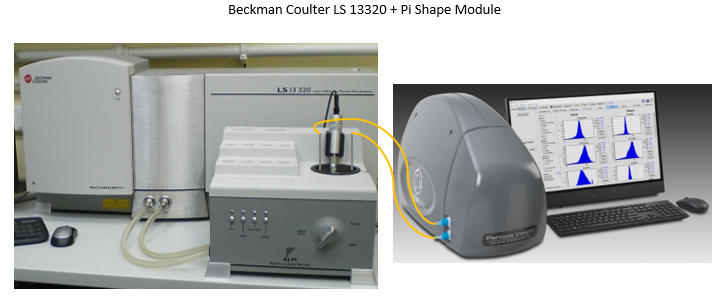

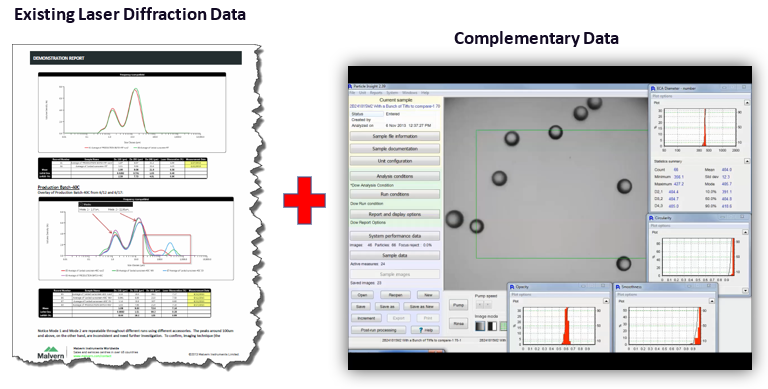

The Pi SM is configured in a way that it inserts easily into the fluidics line of your existing instrumentation. An All-in-One Windows based computer is supplied for dedicated control of the Pi SM, which also provides a real-time display of particle images. Once the analysis is done the user can compare particle size results from their traditional size-only instrument and the shape module.

The Pi SM was developed to be an add-one component to size-only measurement techniques. The Pi SM can plumb into your existing system enabling the measurement of same aliquot of sample for both systems. Being that most techniques in the market assume that particles are spherical in nature when reporting results, having additional shape information as well as particles images in addition to results from current techniques enables the user to gain a better understanding of the particles and how they would perform in their final use.

Advantages

- Simplified application specific for fluidics.

- Designed to be adapted to other particle size analyzers as an add-on module

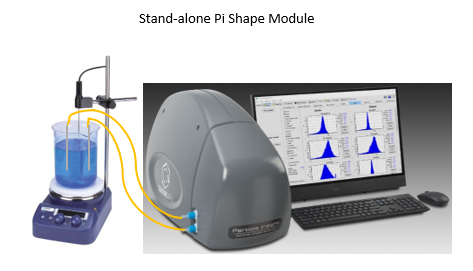

- Can be setup as a stand-alone system

- Allows adaptability to most in-line processes.

Complimentary to Laser Diffraction

Not all particles are round. In fact, very few are in real life. Laser diffraction performs an indirect measurements of size. What this means is that what is being measured in laser diffraction is NOT the actual size of the particle but rather the diffracted angular light intensity that is scattered as a function of size. As a result, this method as well as many others used in industry, assume that particles are spherical in nature when reporting size information. The calculations rendered are based on what is known as Equivalent Spherical Diameter. If the particles being measured are, in fact, round in nature, this would be an acc urate way of checking the size, however if they are not round, and most are not, then assuming they are round when looking at statistical results may lead the operator to believe that the particles will perform one way when in fact they will perform differently.

Not all particles are round. In fact, very few are in real life. Laser diffraction performs an indirect measurements of size. What this means is that what is being measured in laser diffraction is NOT the actual size of the particle but rather the diffracted angular light intensity that is scattered as a function of size. As a result, this method as well as many others used in industry, assume that particles are spherical in nature when reporting size information. The calculations rendered are based on what is known as Equivalent Spherical Diameter. If the particles being measured are, in fact, round in nature, this would be an acc urate way of checking the size, however if they are not round, and most are not, then assuming they are round when looking at statistical results may lead the operator to believe that the particles will perform one way when in fact they will perform differently.

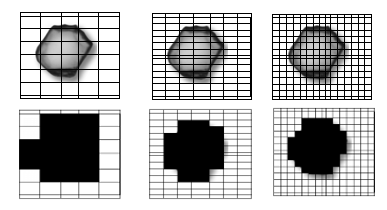

Image Analysis performs a direct measurement of the particle. Unlike Laser Diffraction and other indirect measurement techniques, Image Analysis will take measurements of images of the actual particle. By doing this, calculations can be made to render many different measures about a particle.

In the similar case shown above, the 100 µm diameter particle, assuming it is round in nature, would have up to 30 additional measurements calculated. This gives the user much more confidence to make correct assumptions of how their particles will perform.

Value for the users of Laser Diffraction

- Keep their existing technology. No need to change established specifications or methods.

- Complement with high value shape data to gain more insight into your process.

- All reporting and data can remain the same.

Pi Shape Module New Features

As a new generation of the traditional Particle Insight instrument, the new features are:

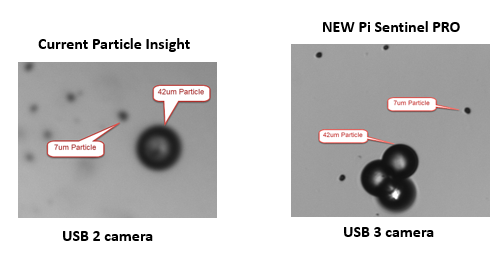

- Improved optics. All components related to image capture (camera and Lens) have been noticeably improved, including easier magnification configuration. Higher speed data transfer rate improves real-time analysis.

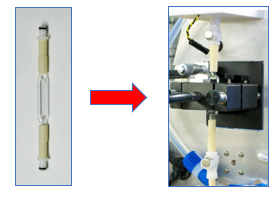

- Improved Light source. The strobe light source has been replaced with a brighter strobe light with an amber filter. This filter reduces the effect of multiple wave lengths when using white light only.

- Improved images. Higher resolution and image capture for better edge definition.

- Improved accuracy. Better accuracy and ability to differentiate minor differences in particle shape down to one micron.

- Improved resolution. USB 3 high resolution digital camera with up to 5 MPs resolution and higher speed data transfer rate and capable of taking up to 127 frames per second rated, captures live images of thousands of particles.

- Improved fluidics. The oscillating pumps have been replaced with stronger peristaltic pumps that use a chemical resistant tubing. Also, the peristaltic pumps are less prone to maintenance issues.

- Pi Sentinel PRO Shape Module has now a Chemical resistant tubing to maintain compatibility for organic solvents. Pi Sentinel PRO SM has replaced the standard tubing for aqueous solvents with chemical resistant tubing that convert the Pi Sentinel PRO Shape Module into an organic compatible module.

- Improved Sample Cell assembly. The Quartz sample cell has been implemented with quick connectors (body and insert) to facilitate easy removal for cleaning purposes, replacement or just change the size of the cell for another size.

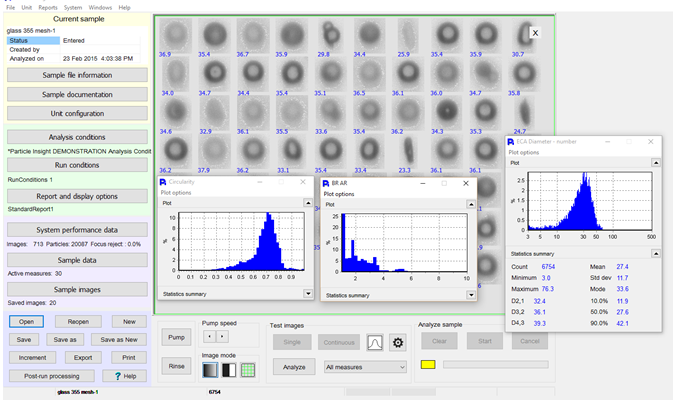

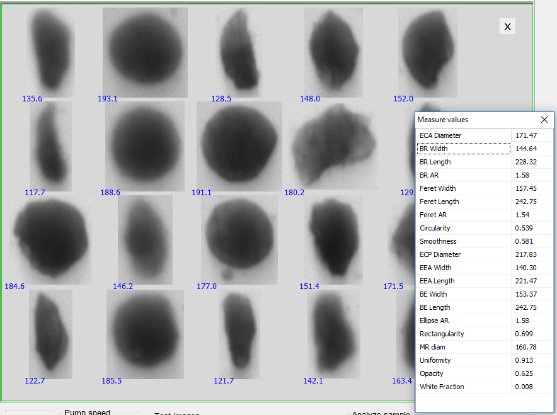

- Improved thumbnail features. When viewing particle thumbnails, the left-mouse button will display all the shape measurement values for that selected thumbnail, the right-mouse button will allow the user to eliminate that specific particle from the database and statistics. Useful when, for example, a single air bubble is not wanted in the database.

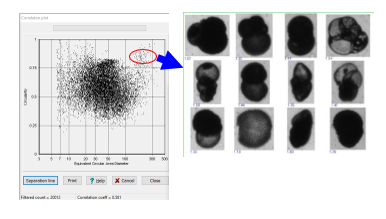

- Improved correlation plot features. Correlation Plot now, able to view thumbnails directly from correlation plot area of interest.

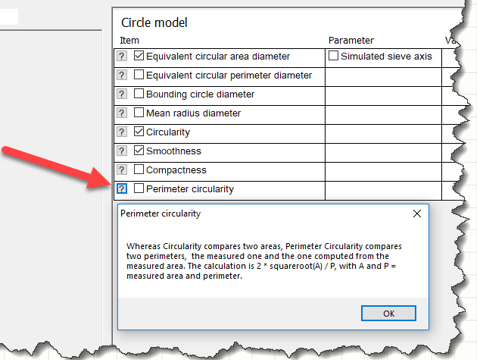

- New perimeter measure. A second Circularity measure was developed called “Perimeter Circularity” to assist customers with existing FPIA systems who have data using this different Circularity measure.

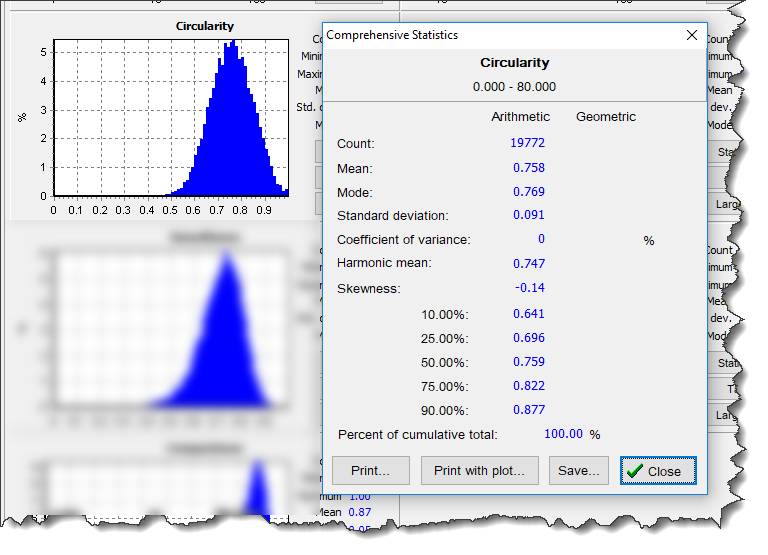

- New 3 digits resolution. Circularity and ALL other fraction measures have data reported with 3-decimal place accuracy. A requirement for transition from FPIA data to Pi Sentinel PRO data.

- New instrument Certification program. IO / OQ Certification and Validation program using NIST traceable standards.

- New Data Integrity compliance. The Certification program complies to new Data Integrity FDA Guidance document.

- New computing platform. Included with every system is an All-in-One computer with touch screen, allowing the customer more interaction with the software features.

- New software interface. The software user interface has been changed to reduce the clutter of options presented to the user. The user still has all the options of the old Pi, they are just accessed differently.

Benefits of the Pi Shape Module:

As a result of the improvements, the benefits are:

- Higher speed data transfer rate, up to 127 frames per second rated digital camera with up to 5 MPs resolution, captures live images of thousands of particles.

- Over 30 shape parameters are recorded, including circularity, ellipticity, opacity, mean diameter, smoothness, aspect ratio, fiber length and many more

- All analyzed particles have thumbnail images saved for post-run viewing and shape analysis, both in grey scale and binary views.

- Ability to compare different analyses via histogram overlays for all analyzed shape parameters.

- Scatter plot correlates two shape measurements and can be utilized as a process quality control criterion as an at-line application within unit operations.

- Unique and powerful software permits the use to simplify data processing to a pass/fail reporting or choose to extend data analysis to a full suite of post processing image and shape analysis reports