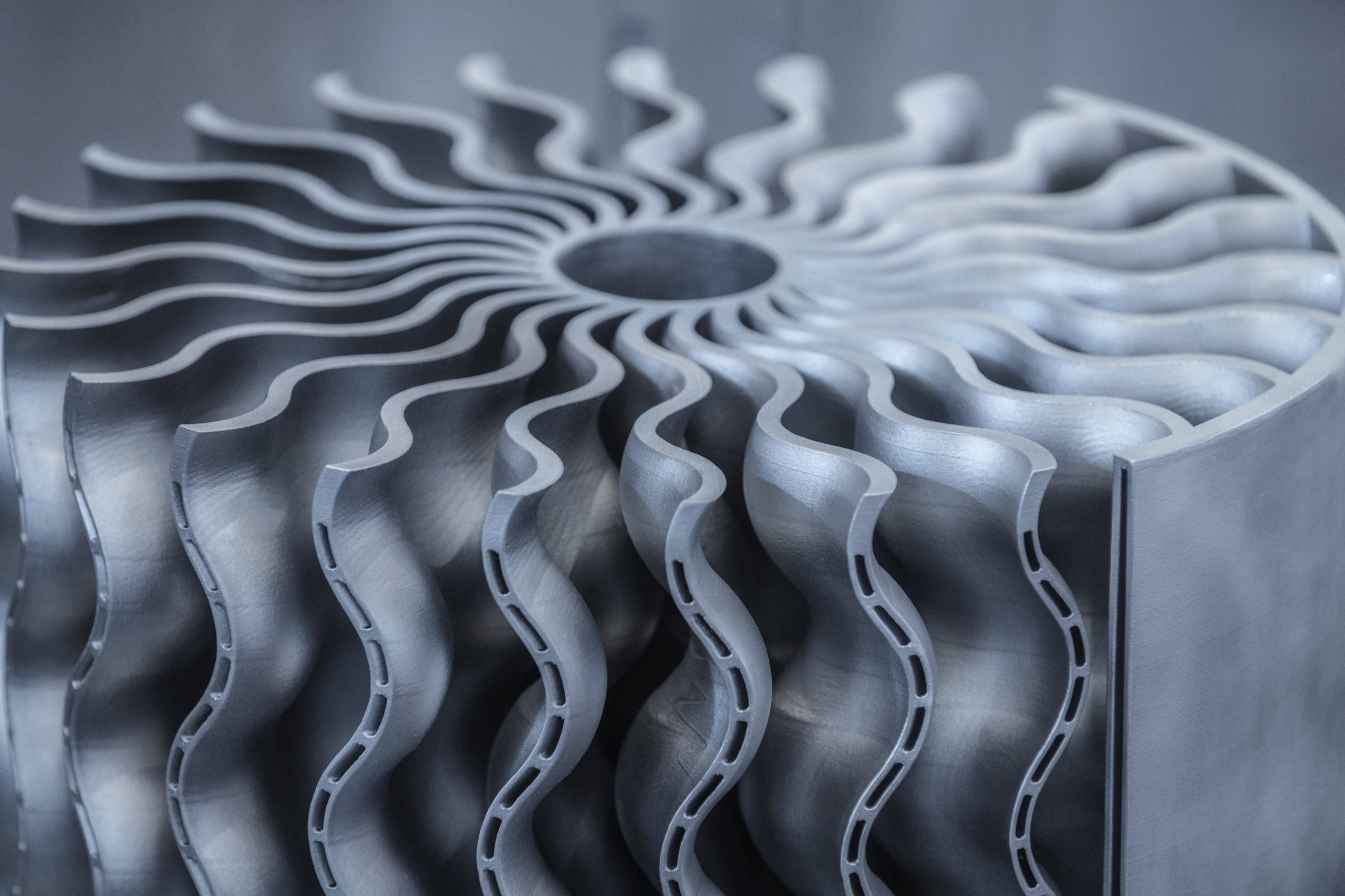

Material identification is a crucial part of the additive manufacturing process, particularly when dealing with metal powder feedstocks. Although metal powder 3D printing is increasingly common, there are various quality assurance and control (QA/QC) challenges that must be considered. There are strict requirements in terms of flowability and sphericity, for instance, plus a need for high degrees of compactness for optimal sintering. These properties are largely dictated by particle size and shape. Thus dynamic image analysis coupled with laser diffraction adds confirmational information to well-established particle size information of metal powder feedstocks.

Why Use Dynamic Image Analysis & Laser Diffraction?

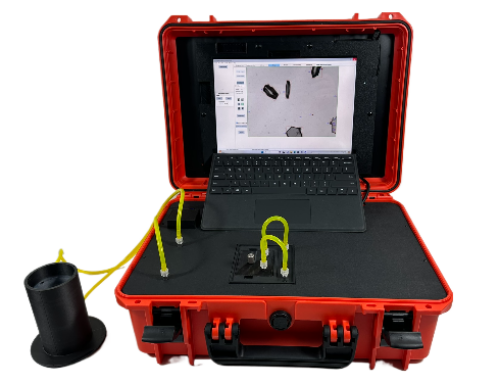

These two techniques are highly complementary methods for rapid, high-throughput screening of metal powders. Laser diffraction is in fact one of the most common methods used for particle sizing, and it lends itself well to additive manufacturing as it offers highly representative data quickly and effectively. Dynamic image analysis complements the rapid size measurements of laser diffraction with critical shape information, likewise in rapid timeframes. The result of combining the two for metal powder identification is a quick and comprehensive overview of the key properties underlying particle quality with respect to optimal deposition and final part quality.

Watch our video on 3D printing metal powder material identification, in which we answer common questions such as: can metal powders be re-used in your 3D printer? Will recycled powders lead to part faults?