Why Particle Shape is important

Indirect size measurement techniques yield results that assume all particles are round. Most particles in industry are not round leaving the user with what can be an incorrect way to determine the behavior of their raw materials.

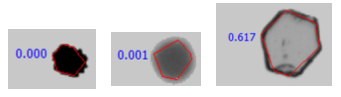

Equivalent Circular Area Diameter

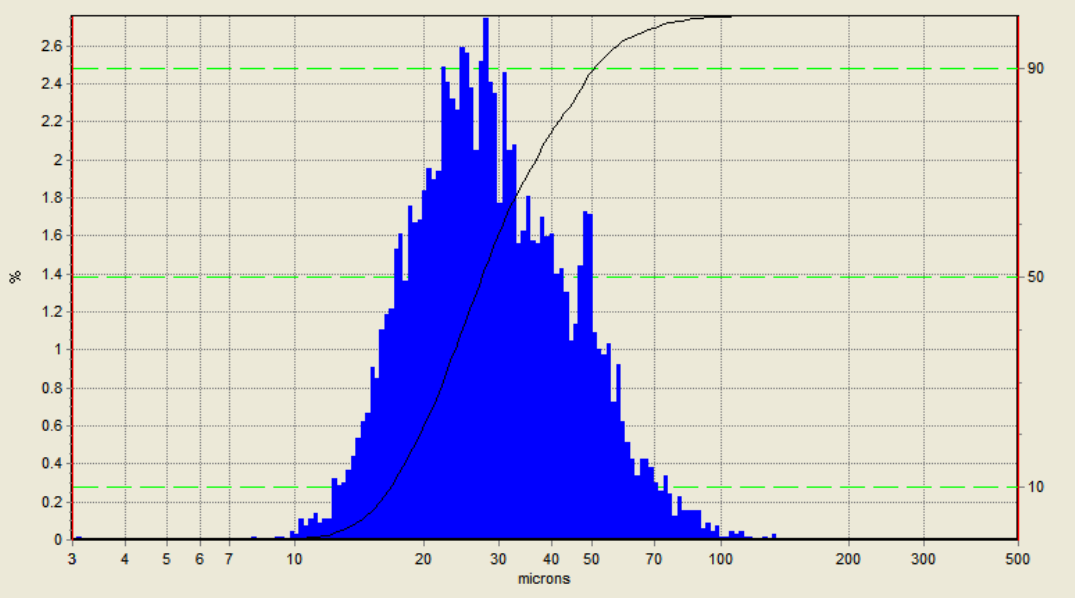

The Histogram below is a typical particle size distribution reporting the size assuming all particles are round leading one to understand that the analyzed particles are all generally the same and about 30 µm in size.

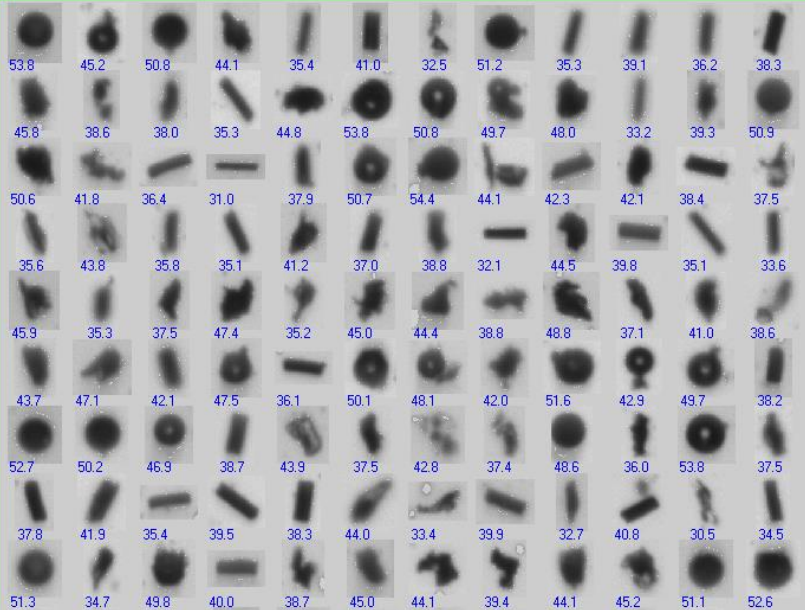

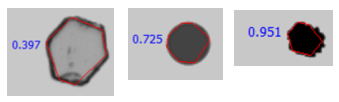

However, by looking at some of the saved particle thumbnails, it is clear that there are actually three different types of particles in this sample. They may all be reported the same if assumed that they are all round, but with Shape analysis, the operator can differentiate exactly what percentage of each sub-population there is in this mixed sample. Additional shape information leads to better decision making based on better insight saving the customer time and money.

Indirect vs Direct measurement techniques

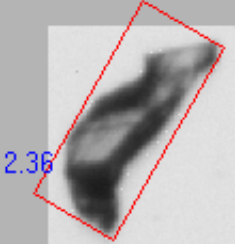

Indirect measurement techniques give results assuming that all particles are round. An incorrect assumption such as this can mislead the operator of the true nature of their raw materials. In this case, this abrasive particle, being represented as a round particle, would lead one to believe that this is a 100.1 µm particle.

Image Analysis is a direct measurement technique which allows the user to obtain more exact information and additional shape parameters about their particles. The added information enables the user to better understand the nature of their raw materials.

The understanding of other shape measures of this particle is critical to the performance of the final product. Abrasive pads for sanding in this case.

- Smoothness is 0.509 where “1” would be a perfectly smooth particle.

- Circularity is 0.321 where “1” would be a perfectly circular particle.

- Bounding Rectangle Aspect Ratio is 2.36 where Width is 82 µm, Length is 193.2 µm.

Listing of All Shape Measures

The Particle Insight has a total of 28 size and shape measures, within 6 different shape models, as well as the ability to correlate any two measures. Normally not all shape models are going to be of use to any one user for any one sample type. However, it is very common to have one or more be of importance.

For example, for a rod-shaped particle, the length and the aspect ratio may both be equally important. Or in the case of an abrasive powder, the Circularity and the Smoothness is important to monitor.

It is important to identify which set of the 6 shape models would best be suited to identify key performance measures for your particles.

For example, if your samples are a mixture of round and rod-like particles and they are separating or are not compacting well, then possibly the ratio of round (circular model) to long (length models) is important to monitor.

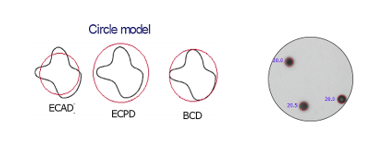

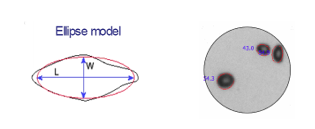

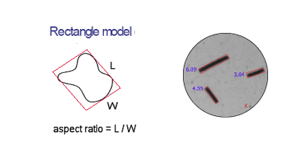

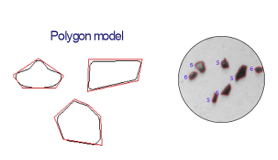

Particle Characterization Shape Models measures

Circle: equivalent area (Heywood) diameter, equivalent perimeter diameter, bounding circle diameter, circularity, form factor, compactness.

Ellipse: equivalent area diameter, bounding ellipse diameter, ellipticity.

Rectangle: bounding rectangle length, width, aspect ratio; rectangularity.

Polygon: polygon order, convexity, interior angles.

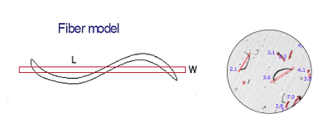

Fiber: length, width, aspect ratio, curl.

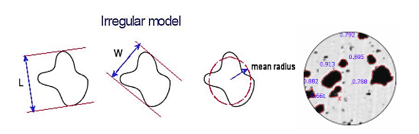

Irregular: Feret length, width, aspect ratio, mean radius, smoothness.

Pixel Intensity: Opacity and White Fraction.

Opacity: The particle’s intensity mean is calculated as a value 0 black) and 255 (white). Opacity is then computed as (256 – (Intensity Mean))/256.

0 is fully transparent, 1 is fully opaque.

White Fraction: White fraction is the fraction of the particle area that is lighter than Dark Threshold in Analysis Conditions options.