A Guide to the Importance of Particle Shape

The Importance of Particle Shape in Material Performance

While particle size has long been a dominant metric in particle analysis, recent advancements show that particle shape plays an equally crucial role in determining the behavior, processing, and final performance of materials. Whether in pharmaceuticals, abrasives, ceramics, or additive manufacturing, the shape of particles influences flowability, compaction, strength, and more.

This guide explores why shape matters, how it is measured, and how modern tools like the Particle Insight Raptor can help you make more informed decisions about your materials.

Why Particle Shape Analysis Matters

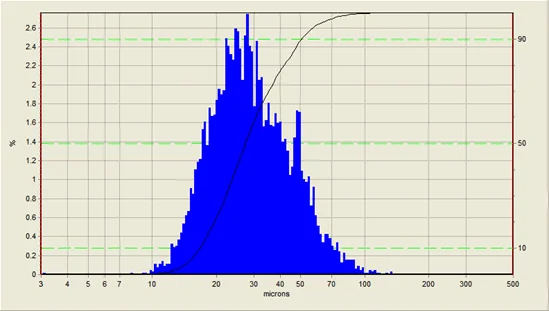

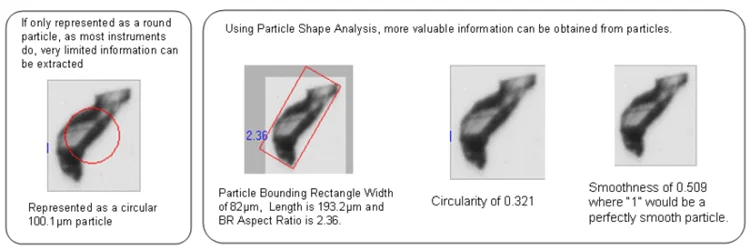

Traditional particle size analyzers — such as laser diffraction or sieve analysis — provide statistical averages but miss critical details about the actual geometry of particles. However, particles with the same size can behave very differently if their shape characteristics vary.

For example, two particles with equal volume might differ in flow or compaction if one is spherical and the other is angular or elongated. Shape analysis helps uncover these subtleties, offering valuable insight into:

- Flow and pack behavior in powders

- Surface area variations (impacting reaction rates)

- Abrasiveness and cutting potential

- Filtration efficiency and clogging risk

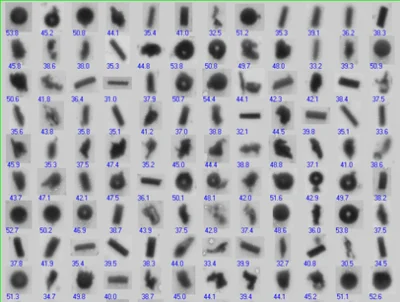

All these particles – spheres, irregular shapes, and fibers – report a size-only equivalent circular diameter of about 40 μm.

The assumption that all particles are spherical can be misleading and will not alert the end user of any issues that can impact the final product.

When powder particles are elongated or fibrous, it is apparent that length and width measures are a necessity at the very least to assess them properly. But even with low-aspect ratios, which means particles are not elongated, they can still be irregular. To predict performance, it may be a requirement to obtain statistics on other shape measures to better classify these irregular particles. For example, lower circularity particles may flow slower and cause samples to segregate while flowing in a process. The same can be said for less-smooth particles or a combination of smoothness, circularity, and size.

Solution

“Circularity” is a measure of roundness of the particle silhouette, and by inference, the degree of sphericity in the range from 0 to 1.0. It is computed from the perimeter and area of the actual particle silhouette. Also, surface smoothness from the shape of the particle outline can be measured.

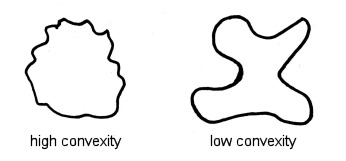

Another measure, “convexity,” reports how “regular” the shape is from a bigger perspective; that is, to the extent it is free of indentations and protrusions. All these measures are possible and significant even for approximately spherical shapes.

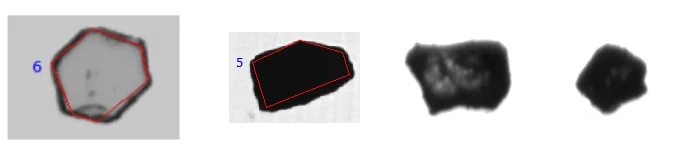

Aspect ratio, circularity and smoothness inform us about non-spherical objects:

In particular industries such as abrasives, it is sometimes of value to garner further shape information, for instance, the number of polygonal sides and the interior angles. Multiple shape parameters are commonly used to quantify and compare lots of different materials or similar materials from various suppliers.

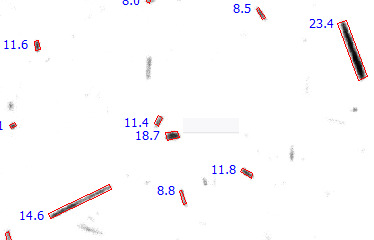

In the case of rectangular or fiber samples, a single size-only value is far from enough to quantify the sample properly. We need to know the distribution of widths present, lengths, or both, and statistics concerning the aspect ratios. Additionally, surface smoothness may be significant in these scenarios and fiber curl.

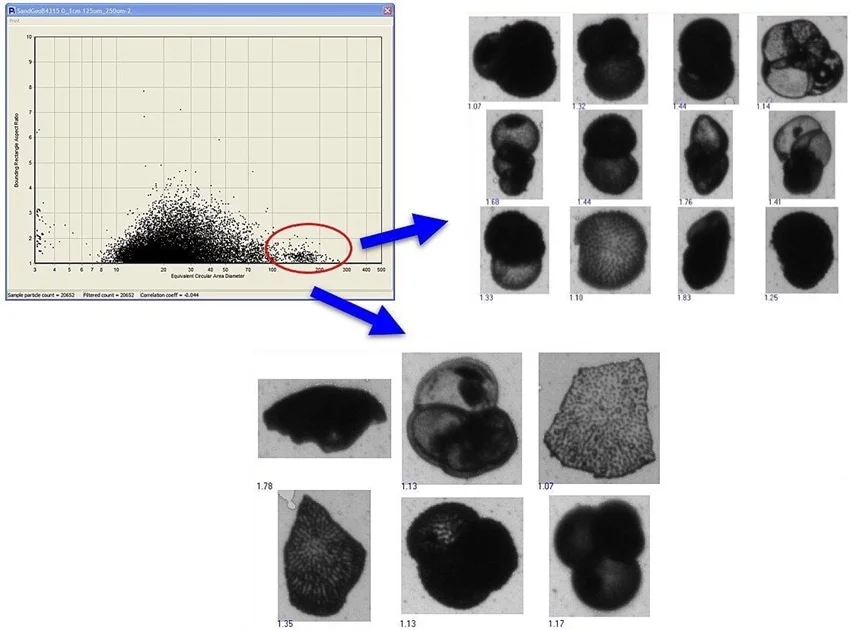

A powerful feature of shape analysis is the ability to correlate shape statistics with size statistics to view how shape transforms with size. This is formed as a scatter diagram, with one point representing each particle. This correlation plot displays all the analyzed particles correlated by any two shape measures and enables the user to then view any or all of the particle thumbnails of interest. This is an ideal tool for identifying rare events of a few particles in a large population of tens of thousands of analyzed particles.

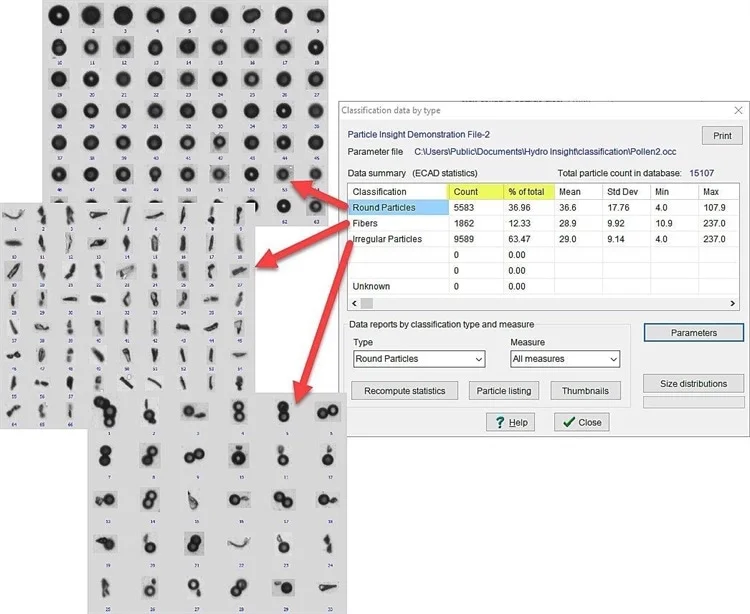

Another powerful feature of shape analysis is defining subcategories contained in a sample using size and shape simultaneously. This classification feature enables the independent investigation of two or more classes of particles. Statistics can be derived from any of the classes at one time, thumbnail images for each class can be viewed, and each class’s percentage can be reported.

In summary, the importance of particle shape, not just size, is important in many industries.

Common Shape Parameters and Their Significance

The Particle Insight Raptor system measures over 30 shape parameters, but some of the most impactful include:

Circularity

Measures how close a particle’s outline is to a perfect circle. Lower circularity often indicates rough or jagged edges.

Convexity

Indicates the smoothness of the particle contour. Low convexity implies concavities or indentations — often seen in agglomerates or broken particles.

Aspect Ratio

Compares particle length to width. High aspect ratios often correspond to rod- or fiber-like particles, while values near 1.0 indicate rounder shapes.

By analyzing these metrics, users can classify material behavior, monitor for contamination, or ensure manufacturing consistency.

Dynamic Image Analysis: The Modern Approach

The Particle Insight Raptor uses Dynamic Image Analysis (DIA) to capture and measure thousands of particles in real time. Unlike older methods, DIA provides both size and shape data simultaneously, along with actual thumbnail images of the particles.

This offers several benefits:

- Visual confirmation of shape categories

- Detection of agglomerates and broken particles

- Automated shape classification with user-defined thresholds

Real-World Applications of Shape Analysis

- Pharmaceuticals: Ensures optimal drug delivery and tablet formation

- Abrasives: Monitors cutting efficiency and uniformity

- Ceramics: Predicts sintering behavior and density

- Filtration Media: Identifies fines or shape anomalies that could clog systems

Conclusion

Particle shape is more than just an academic interest — it’s a powerful predictor of product performance. With tools like the Particle Insight Raptor, your lab can go beyond averages to uncover the true identity of your materials.

Explore More

Want Help Understanding Your Particle Shape Data?

Contact Vision Analytical to schedule a demo or get a customized application analysis for your material. Our team will help you identify how particle shape impacts your process and how you can take control with image-based analytics.

Frequently Asked Questions (FAQ)

What is particle circularity and why is it important?

Particle circularity measures how closely a particle resembles a perfect circle. It affects flow behavior and is useful for detecting rough, irregular particles that may influence product performance.

How does particle shape affect flowability?

Rounder particles tend to flow more easily, while elongated or angular particles can interlock or resist movement — impacting everything from hopper discharge to tablet compression.

Is shape analysis better than just measuring size?

Not better — but more complete. Size alone doesn’t tell the full story. Shape analysis adds depth, helping detect contamination, improve quality control, and optimize processing.