APPLICATION NOTE: AN-003

Dynamic Image Analysis of suspended liquid particles

Irregularly shaped particles require analysis with random orientation to ensure accurate results.

Introduction

In various industries, it is important to measure the size of liquid particles in a suspension. These could be as simple as oil droplets suspended in water or water droplets suspended in oil. There are other instances in pharmaceutical applications where liquid dosages may be encapsulated inside a harder outer shell. In many of these cases, the end user may have a need to determine the size of these globules, the shape, and possibly the concentration. However, the challenge is using an automated technique that can differentiate between a water droplet and an oil droplet as well as to differentiate these particles of interest from other debris as to not impact the concentration measurements. The most common particle measurement techniques can only differentiate particles based on size. In addition, most of these common techniques will assume all particles are spherical in shape, which for this globule application is an accurate assumption unless there are non-spherical particles, such as debris, that could incorrectly be measured as part of the main population of particles. In addition, some of the more common techniques require supplementary information about the particles as well as the fluid they are suspended in.

Parameters such as refractive index may be needed to properly measure particles. Given that globules are of one, or various, refractive indexes and the liquid they are suspended in are of a different refractive index, performing measurements of globules present a challenge using some of the more common particle size measurement techniques. The differentiation between droplet types and debris is also difficult to do with size-only measurement techniques. Because of this, it is difficult to use the more common techniques to properly measure concentration and to even detect globules suspended in liquid. End users are then limited to use manual microscopy to ensure the particles in question are being identified and measured properly. Microscopy allows the end user to view the particles in question and to differentiate one type of globule from another visually. In addition, it allows the user to identify debris or other particles that are not globules to ignore them or act on the fact that they are present in the sample. The problem is that these manual methods tend to be tedious and time consuming.

In addition, manual microscopy is not a practical technique for measuring an adequate population of sample to ensure statistical assurance. Microscopy also has a tendency of deforming the sample as it is put on a microscope slide. Something not experienced in Dynamic Image Analysis where globules can flow freely.

Combining the speed and accuracy of the more common methods with the visual abilities of microscopy has been accomplished with Dynamic Image Analysis. This method enables users to differentiate not only on size, but also on numerous other shape parameters in a high-speed automated measurement. Dynamic Image Analysis works on the principle that as particles pass through a detection zone, images are captured and analyzed. ISO 13322-2 is used as the guideline for all Dynamic Image Analysis instruments available on the market today. The key benefit of using Image Analysis for globule measurement is the identification, quantification and differentiation of different particles by using Size, Shape, and Opacity shape measurements. The end user would be able in a single analysis perform a size / shape measurement, have a concentration measurement of each type of particle type present and have thumbnail images of each measured particle. Globules made of different liquids, silicone, water, oil, etc., all tend to be spherical in nature and can have random sizes, but all would have different opacity (darkness) that could be detected and used as a differentiation discriminator of each type of globule. In addition, the presence of debris (non-globules) would also be captured and reported. One additional benefit that Dynamic Image Analysis brings is the ability to show particle thumbnails of each measured particle for visual confirmation and identification.

Experimental #1:

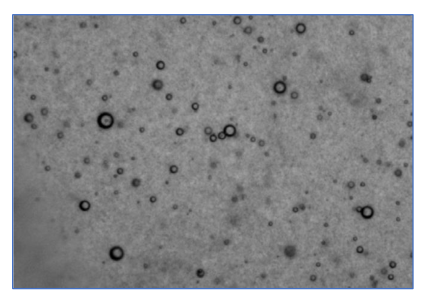

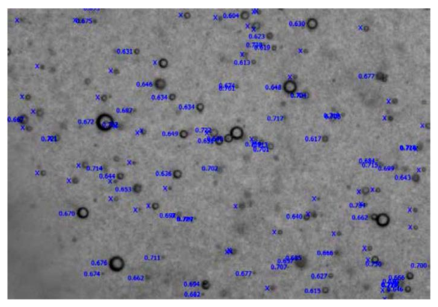

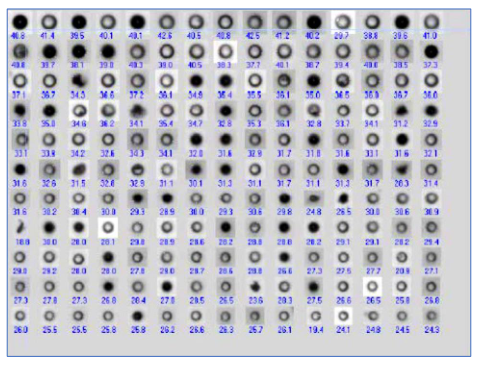

For this experiment the Pi Sentinel PRO, Particle Shape and Size Analyzer was used to measure an oil sample from an airplane engine. In this case the engine had significant wear and thus resulted in cooling liquid (water based) present in the oil. Below is a single screen capture of the sample analyzed on the Pi Sentinel PRO.

In a real-time basis, the Pi Sentinel PRO can analyze the particles on the screen and perform 30 shape measurements as well as save the individual particle thumbnail images. As can be seen here, the Pi Sentinel PRO can eliminate or ignore particles that are out of focus. In this case the measurements shown are for the Opacity of each particle. It is also interesting to point out that water droplets in oil come in different sizes however debris that was also found in this sample was distinguishable by their irregular shapes (lower Circularity values, lower Smoothness values and darker Opacity values).

Thousands of particles were measured in a matter of a few minutes. However, because the Pi Sentinel PRO has no lower limit on concentration detection, even if very few particles were present, the recirculating of the sample would capture any rare event particles.

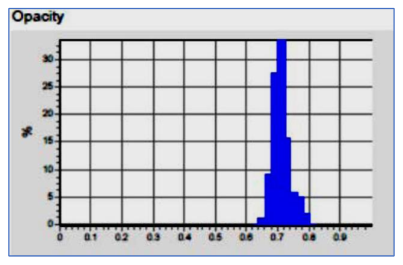

Typical Opacity histogram showing distribution of particles based on how dark they are. Air bubbles and debris tend to have a higher Opacity value than liquid globules.

Experimental #2:

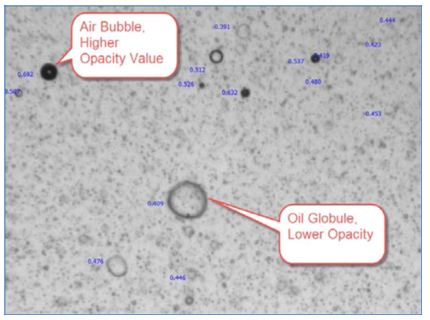

This next experiment was the detection of oil droplets in water. As can be seen here, there are large oil globules as well as some air bubbles. The easy way for the Pi Sentinel PRO to differentiate between an oil droplet and an air bubble was using the opacity measurement.

Smaller debris is present as can be seen in the background. The smaller debris can also be measured in real-time or the instrument settings can be adjusted to ignore them.

After analyzing tens of thousands of particles in minutes, the Pi Sentinel PRO shows all thumbnail images.

As can be seen here, lighter round particles are globules while darker round particles are air bubbles and darker irregular particles are debris. Relative concentration of all three populations can be given and important to know.

Experimental #3:

Conclusion

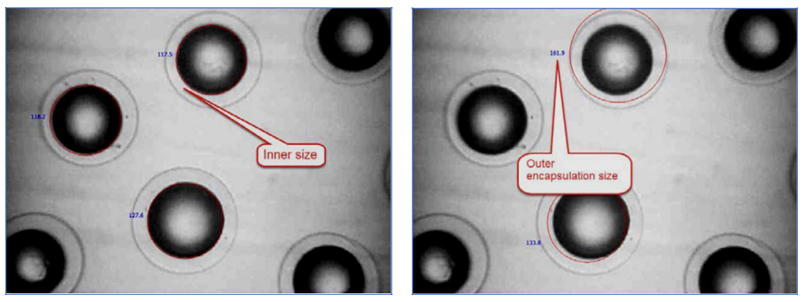

The images below were from a pharmaceutical time released sample that has an inner globule encapsulated in a hard-outer shell. In this sample the customer was interested in determining the thickness of the coating.

All particle size instruments can measure the inner particle when not coated and report the same size because these are spheres.

After the particles have been coated is where most other particle size instruments have a problem. Because the coating is clear optical instruments like light obscuration and laser diffraction will not be able to exclude the inner particle from the analysis and with the clear coating issue with the suspending liquid can cause the outer shell to disappear. For opaque coatings all particle size instruments will be able to measure the coating.

The Pi Sentinel PRO has advantages over the few other instruments that can also measure the clear outer shell and has advantages over sizing opaque coatings.

For clear coatings, the Pi Sentinel PRO can measure both the inner and outer particles in one analysis, because Dynamic Image Analysis offers the ability to change the dark threshold of image detection. The Pi Sentinel PRO could perform an automated analysis of the sample analyzing the inner globule particle. Once this analysis was completed, the same sample was then analyzed with a different threshold condition where only the outer ring (the shell) was analyzed for size and shape.

Another advantage the Pi Sentinel PRO offers for coatings, clear or opaque, is how uniform the coating is. The coating can be test for Circularity, Smoothness, uniformity. Finally, for clear coatings the images saved during the analysis can be viewed to see how centered the spheres are in the coatings. Also, if the coated particles are place is a solution that dissolves the coating the images and shape measure will show how evenly the coating dissolves.

Results and discussions:

In all the above experiments the suspension liquid was of different opacities.

- In the case of the encapsulated globules, the suspension liquid was clear.

- In the case of the oil samples, the suspension liquid was dark used oil. Regardless of this, the Pi Sentinel PRO could detect the suspended globule particles. In addition, having the particle thumbnails available enabled us to ensure that the proper parameters were set to capture the particles in question.

- In the oil in water and the water/air bubble in oil analysis, there was a clear differentiation in Opacity that enabled us to determine the percentage of water particles present, the percentage of air bubbles present as well as the percentage of debris present in the sample.

In this case the end user could determine the health of the equipment where this fluid came from and was then used as a quality control tool to check the stability of the engine from time to time.

In the case of the encapsulated globule, the end user could perform the analysis on a single aliquot of sample. This was a very efficient way to perform the test and did not require the end user to break the outer shell to do a size determination of the inner globule.

Conclusions:

Liquid or globule particles suspended in other liquids would present difficulties for proper detection using typical size measurement techniques.

The Pi Sentinel PRO using Dynamic Image Analysis has shown to be a valuable tool in the analysis and differentiation of these particle suspensions. In addition, the ability to have particle thumbnails enables a visual validation of the analysis.