APPLICATION NOTE: AN-002

The Importance of Random Orientation When Measuring Particle Shape

Irregularly shaped particles require analysis with random orientation to ensure accurate results.

Introduction

Particle shape is becoming more and more recognized in industry as a desirable way to monitor many industrial materials and processes. In many applications, the circularity of particles can affect both performance and flowability in manufacturing. In some cases, for example, measuring surface smoothness can impact how abrasives will perform.

For those who have realized that irregularity of their particles impact both manufacturability and efficacy, microscopy for shape analysis, historically, has been the solution. Microscopy (also known as static image analysis) orients particles so that the largest area of the particle faces the viewing point. This technique may be enough for providing a general idea of particle shape but is insufficient when using particle shape analysis to control a process.

Obtaining data from forced oriented particles provides only a portion of the information required for a full understanding of how particles will perform. Instrumentation providing limited information can lead to incorrect assumptions about raw material and, in turn, impact performance of the final product. Therefore, a particle shape system being used for process control must be capable of fully analyzing all dimensions of particles.

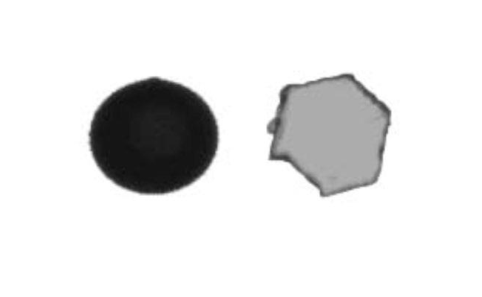

Figure 1 shows a polystyrene latex bead, which is spherical, and a particle that is a flat disc. Although both yield similar results in equivalent spherical diameter, the sphere on the left is quite different from the flat disc on the right. A system that orients the largest area of the particle at the viewing point would be unable to see all dimensions of the particle.

Figure 1

To a static image analysis system or microscope that orients the largest area of the particle toward the viewing point, these particles are reported as the same and render similar equivalent spherical size data. However, by the very nature of their shape, these particles would flow differently in a manufacturing process and have a different impact on the final product.

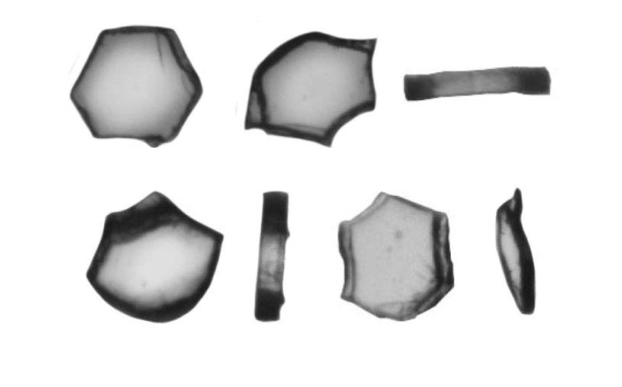

Figure 2 shows a crystal-like sample, which is flat and hexagonal in shape. These sample characteristics have been determined using the Pi Sentinel PRO Dynamic Image analyzer, which is designed for random particle orientation. The Pi Sentinel PRO also recirculates the sample like a traditional Laser Diffraction system.

Figure 2

Typical particle thumbnails from a Dynamic Image Analysis system. Notice random orientation allows the analysis of all dimensions of the particle, not just the largest area.

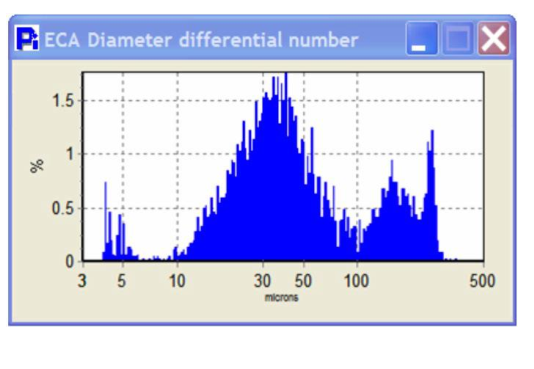

Random orientation (for capturing true particle dimension) and recirculation of the sample (for statistical accuracy) are two features which have been instrumental in standardizing laser diffraction in process control for many raw materials worldwide. Figure 3 displays plotted results of the sample crystals shown in Figure 2.

Statistical results for flat particles. Note the peaks above 100 μm are the particles that had their largest area oriented toward the viewing point. The particles under 100 μm are variations of particles being analyzed on their other orientations.

Figure 3

Conclusion

The purpose of the Pi Sentinel PRO is to provide the user with accurate results so that their process can be monitored or adjusted. By having such a system, the user can rest assured that the data being obtained are a true representation of their sample.

In this application, it is evident that random orientation provides a better representation of the sample and is the preferred method when true particle shape is critical to the efficacy of the final product. The Pi Sentinel PRO from Vision Analytical Inc. employs two important features: random orientation and recirculation of the sample. These two features help to a ensure a true representation of the sample and accurate data.