Comprehensive Particle Shape Analysis of Abrasive Powders

Abrasive powders play a crucial role in industries such as polishing, grinding, and cutting, where particle size and shape are key factors in determining performance and effectiveness. Particle size impacts cutting and abrading efficiency, with finer particles delivering smooth, polished finishes and larger particles enabling more aggressive material removal. Particle shape is equally important—angular particles create sharp cutting edges for precision work, while spherical particles ensure smoother finishes and minimize surface damage. By precisely analyzing and controlling these characteristics, industries can optimize abrasive performance, ensure consistency, and achieve superior results in applications like surface finishing and precision machining.

The Critical Role of Particle Size and Shape in Abrasive Powders

The performance of abrasive powders depends on more than just grit size—it is significantly influenced by particle size, particle shape, and surface smoothness. Coarser grits, with larger particle sizes, excel at material removal, but particle shape is a decisive factor in efficiency. Angular and irregularly shaped particles provide sharper cutting edges, enhancing removal performance, while smooth, rounded particles are less effective in aggressive material removal.

This analysis explores various abrasive powders, highlighting differences in particle size across grit classifications and evaluating how shape and smoothness impact performance. To achieve consistent and optimal results in applications like material removal and surface finishing, precise control and evaluation of both particle size and shape are essential.

Procedures and results used to maximize Dynamic Imaging as a tool to control quality of abrasive powders

Comprehensive Particle Size and Shape Analysis of Abrasive Powders

In this study, multiple abrasive powder samples were analyzed, representing three distinct grit classifications. While manufacturers of abrasive powders often rely on size-only calibration to evaluate product quality before distribution—primarily for applications like polishing and sandpaper production—this approach overlooks a critical factor: particle shape.

Traditional particle-size-only equipment assumes particles are spherical, failing to account for shape properties. While this may suffice for some raw materials, it is inadequate for applications where particle smoothness and angularity directly affect performance. Accurate shape analysis is essential for ensuring optimal abrasive efficiency and surface finishes.

The Insight series of products revolutionizes this process by analyzing thousands of particles within minutes, delivering over 32 size and shape measurements. For this report, the Particle Insight analyzer performed advanced statistical evaluations of particle smoothness, enabling operators to identify out-of-spec particles and ensure consistent quality across samples.

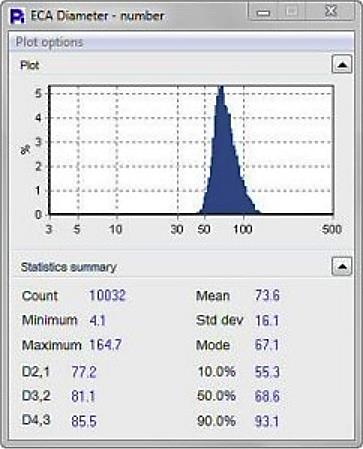

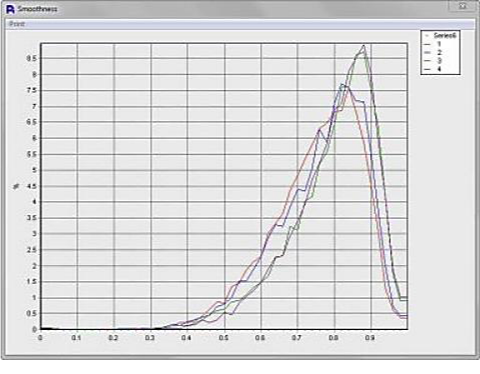

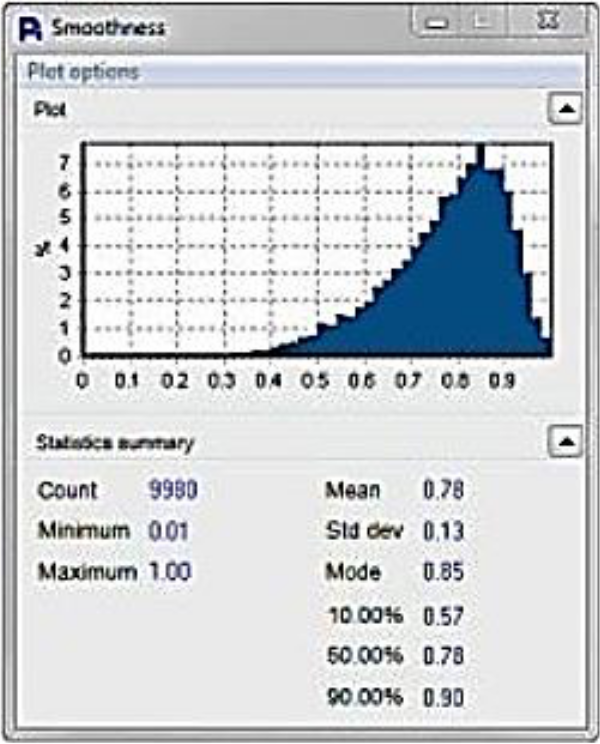

Abrasive powders of certain grit dimensions record an average diameter of 73.6 microns. However, this number only represents a rough size calculation and is a reporting assuming the particles are all round in shape. Surface smoothness yields a more satisfactory means of characterizing of the particles. Smoothness of each of the measured particles is exhibited as a statistical histogram below. For this very reason dynamic imaging is reports more than just one statistical value for a sample. By using more than one, it offers a greater ability to differentiate one sub-population from another.

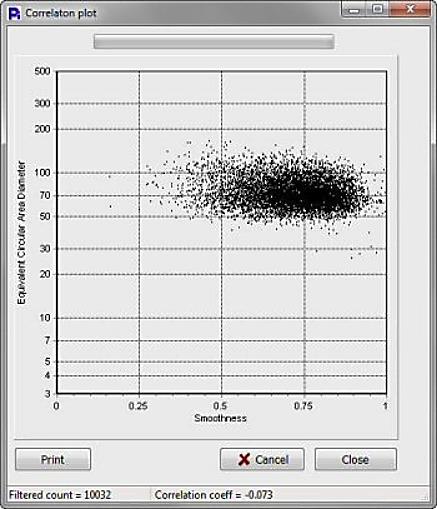

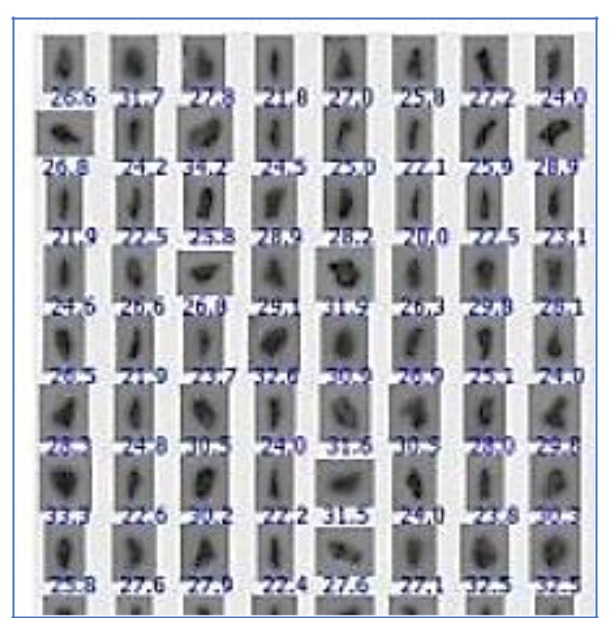

The Particle Insight series of products permits the correlation of any two size/shape measurements. A scatter graph of each of these abrasive particles, plotted according to size and smoothness, is presented here. The correlation plot demonstrates that size and smoothness are almost always independent of each other.

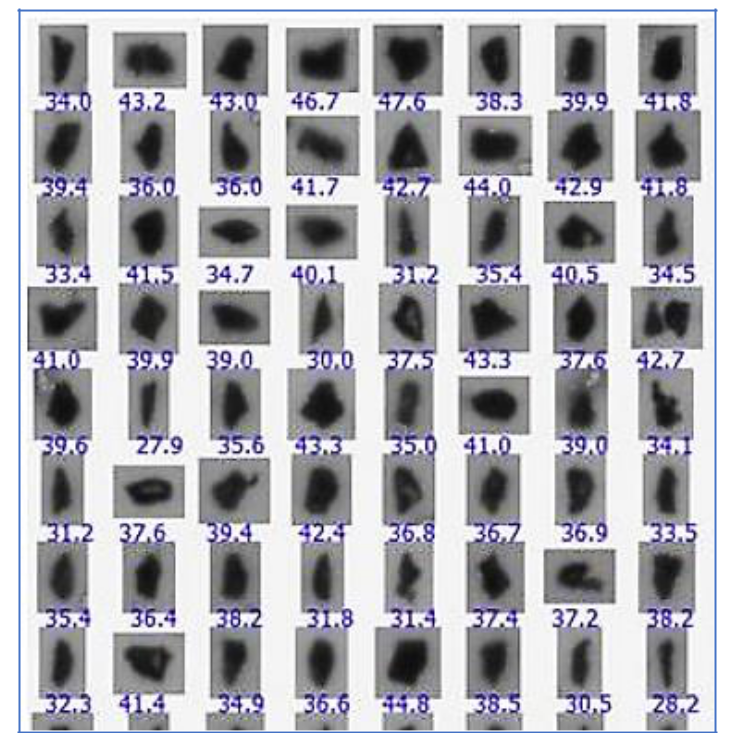

What is unique here is not just the scattergram or scatterplot but the fact that this is a functional plot. Any user can zoom into any portion of this plot and view the particles each dot represents. This allows the user to go from this identification tool to direct objective evidence of a population of interest using thumbnail images.

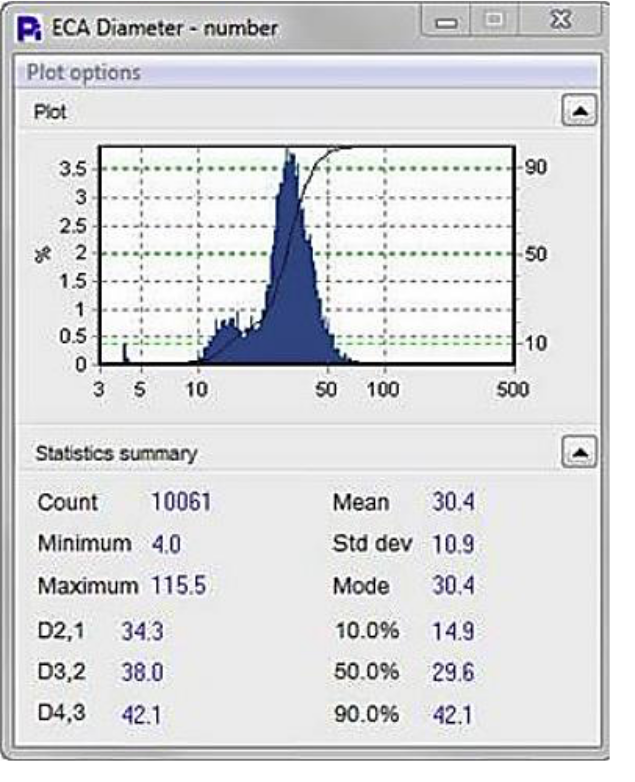

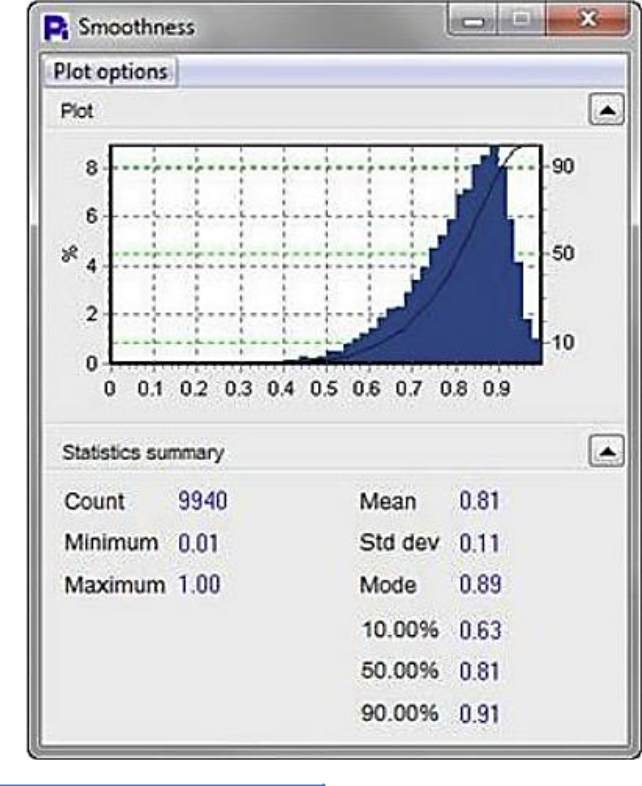

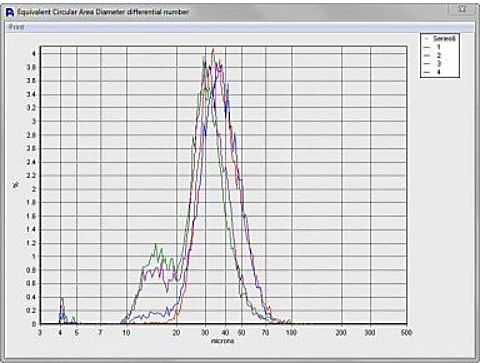

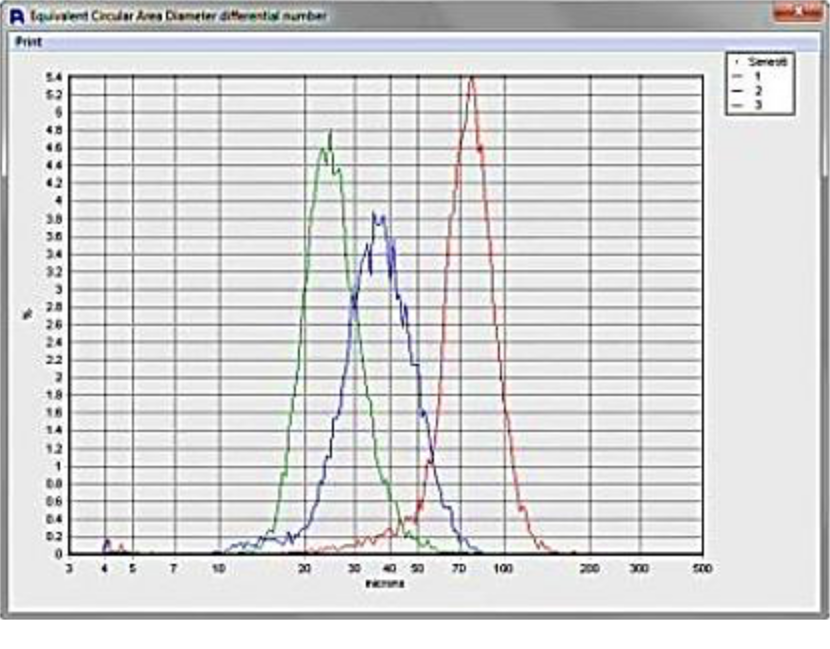

Abrasive powders of a higher grit number, or finer particles, are presented here. The average size of these particles is smaller, 30.4 microns, but the average smoothness of 0.81 (1 representing perfect smoothness) is roughly the same as the prior case.

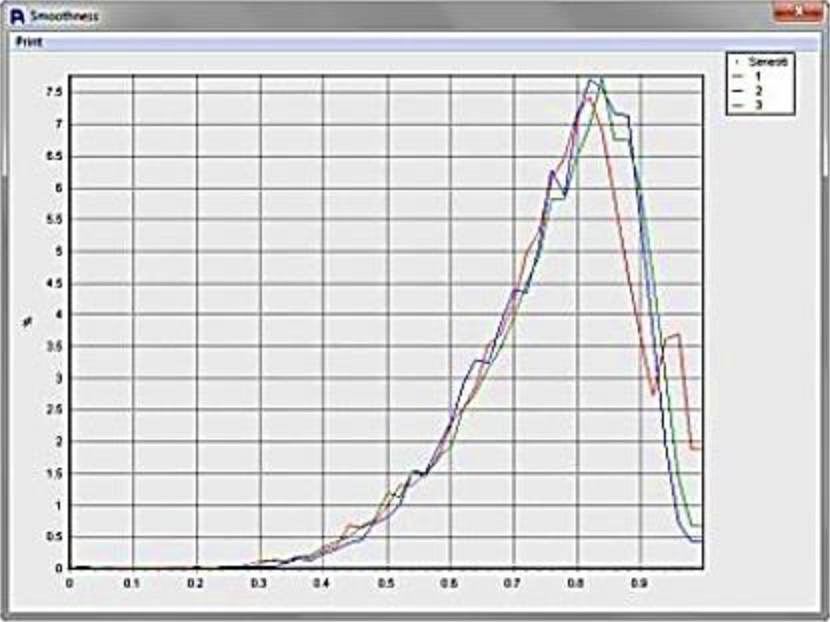

Moreover, the Particle Insight series of products can overlay various samples on the same plot to enable differentiation of size and shape measurements. Some samples overlay in size adequately, but possess a high ratio of fine particles, as shown here. Nevertheless, the fine particles do not affect the general smoothness; the smoothness of these particles is comparable to that of the larger particles.

It is always important to do overlays and comparisons both looking at a number weighted distribution as well as a volume weighted distribution. Click here why this is important

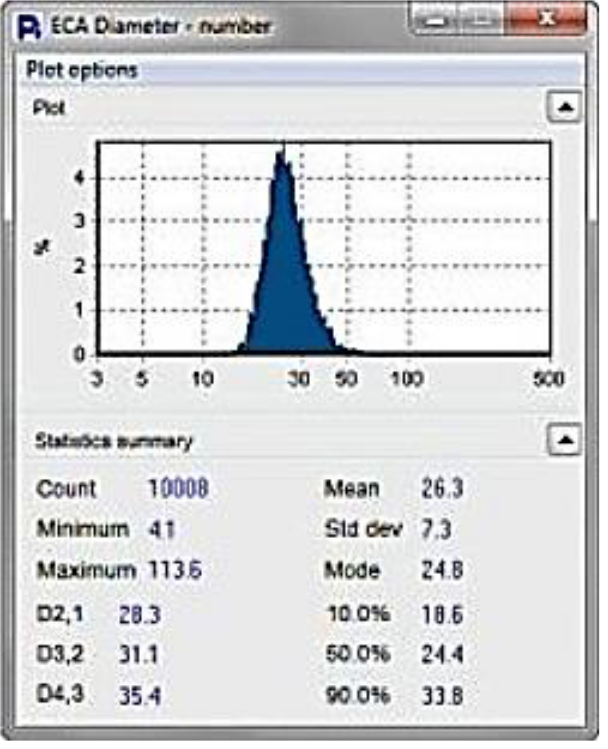

Even finer particles with a size of around 26.3 microns are presented here. As before, while the size of the particles decreases in inverse proportion to the grit number, the smoothness of the abrasive particles is still comparable with that of the other grit powders.

Even finer particles with a size of around 26.3 microns are presented here. As before, it can be seen that, while the size of the particles decreases in inverse proportion to the grit number, the smoothness of the abrasive particles is still comparable with that of the other grit powders.

Conclusion

Analysis of the three separate grits of abrasive powders yielded three different particle sizes, as would be expected. However, this study reveals that, irrespective of the size or grit of the abrasive powders, their smoothness remained remarkably homogeneous. This indicates that the grinding processes employed by the manufacturers of these abrasive powders is adequately regulated. This smoothness constancy, irrespective of size, is an important way of ensuring performance consistency, whatever the abrasive particles’ end use.

Another identifiable feature of the Particle Insight series is that, because it performs a direct measurement technique, operating on a counting or single-particle basis, if there are any large, undesirable particles, these can easily be identified. This identification is executed using the number-based distribution and data for any individual particle, but also by observing the thumbnails for each out-of-specification particle. After all, no consumer would want to polish their car with a product containing even one large unwanted particle.

For a deeper understanding, visit our Basics of Particle Characterization page.