APPLICATION NOTE: AN-001

Particle Shape Analysis of Fiber Particles

Introduction

Automated image analysis has been developed to provide users with a more accurate measurement of their particles. For many years, particle size analyzers have rendered results with the assumption that all measured particles are spherical. However, in many applications, the circularity of particles can affect both performance and flowability in manufacturing. In some cases, for example, measuring surface smoothness can impact how well abrasives perform. Those in industry who have realized that the irregularity of their particles impact both manufacturability and efficacy have resorted to microscopy for shape analysis. Manual microscopy, by its very nature, is a slow and tedious method for particle analysis and becomes impractical to analyze many particles. Therefore, the end-user potentially is left with a poor representation of the sample. This makes microscopy acceptable for obtaining a general idea of particle shape, but is unacceptable when using particle shape analysis to control a process. One raw material which lends itself to be ideally measured by shape analysis is fibers. Fiber particles are used in a vast array of applications from adding strength to building materials to making effective filtration media. In all cases where raw fibers are used, there has been an expressed need to know the fiber length, width, and aspect ratio, as well as the curl of the fiber. Particle analysis results expressed in equivalent spherical diameter do not come close to giving the user critical information about their fibers, and how they will perform in their final state. Measuring such particles with manual microscopy is also impractical in a quality control environment where fast and representative analysis is required.

Figure 1 shows a typical fiber in the sample analyzed using the Pi Sentinel PRO Dynamic Image Analyzer from Vision Analytical Inc.

Figure 1: Fiber sample used for analysis

Analysis of this fiber sample with a conventional particle size analyzer assumes all particles are spheres, and reports minimal information; in this instance, a size of 112.1 μm. Analysis of the same fiber sample using the Pi Sentinel PRO Image analyzer, a proper-shape analyzer with fiber-shape measures, can yield much more information on a high population of particles in just minutes. The measurement of fiber length and width is calculated along with the aspect ratio, which is simply the length divided by the width. Another measurement that can be calculated is the fiber curl, a fractional measure that is equal to 1 for a straight fiber. The smaller the fiber curl value, the greater degree of curvature the fiber has. This can be very useful in making determinations of how fibers will interact with each other in a production process.

Applicable measures:

These four fiber-specific measurements made with a Pi Sentinel PRO are summarized below:

Fiber Length: 449.9 μm

Fiber Width: 22.7 μm

Fiber Aspect Ratio: 19.82

Fiber Curl: 0.984

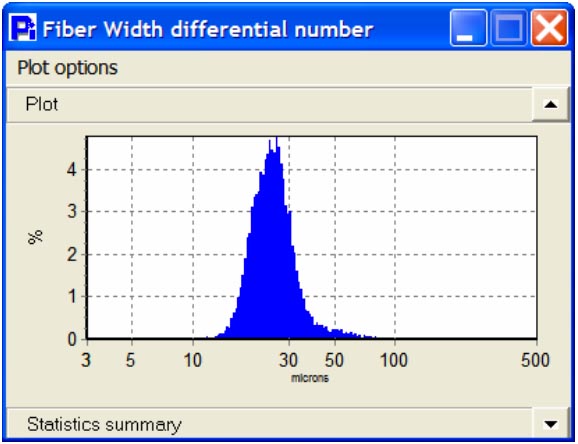

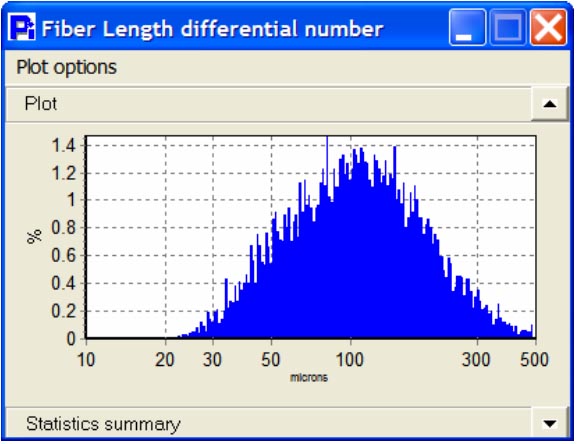

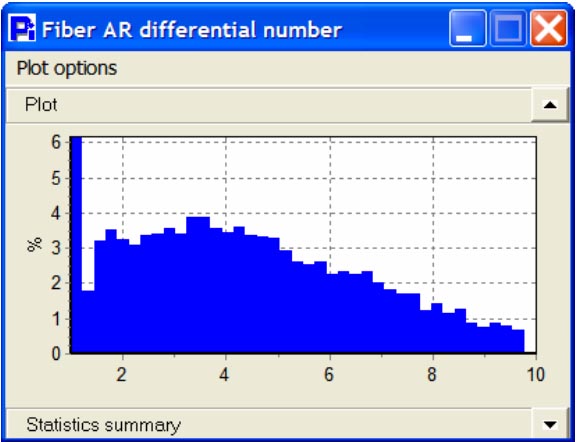

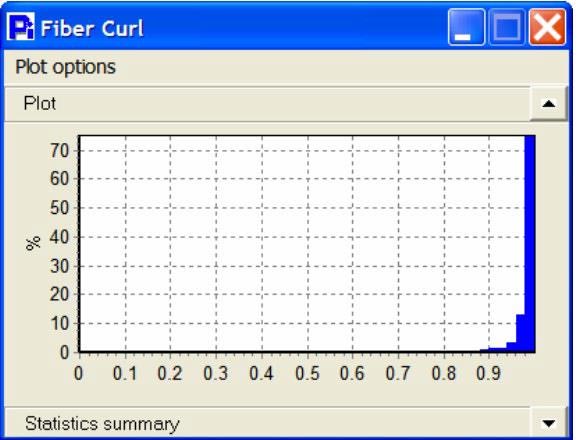

Figures 2 through 5 provide additional data statistics as indicated in the figure captions.

Figure 2: Indicates the width of these fibers were rather uniform in nature. A total of 10,000 particles was analyzed in 149 seconds.

Figure 3: Shows the average length of the fibers to have a mean of 123 μm with a standard deviation of 74.8 μm.

Figure 4: Although the width of the fibers is well controlled, the length is not. As a result, the aspect ratio results are broad. Here the aspect ratio shows a mean of 4.450 with a standard deviation of 2.262.

Figure 5: The mean fiber curl is 0.97 with a mode fiber curl of 0.99. This clearly indicates that the population of fibers is mostly non-curled.

Conclusion

It is important to select a particle size analyzer that can properly analyze the parameters that are important. As can be seen, measuring a fiber with the assumption that they are spherical in shape may not be the most accurate method for quantification. Size, in this case, was not enough to give the user a true and accurate measure of the fibers. In the case of the fiber samples in this application, it was much more revealing to use the four fiber-specific measures:

• Fiber Width differential number.

• Fiber Length differential number.

• Fiber AR differential number.

• Fiber Curl.

from the Pi Sentinel PRO to gain a better understanding of the particles and, possibly, in their manufacturing process. It is also very practical to use one or more of these fiber-specific measures as a Quality Control specification given that the analysis is accurate, fast, and can measure thousands of Save particles in seconds.