Particle Shape and Size Analysis of Toner Powder for Laser Printers

Overview

Toner powder is a critical component in laser printers and photocopiers, composed primarily of carbon mixed with various polymers. Each printer manufacturer customizes its toner formulation to meet specific performance goals. Among the most vital characteristics in these formulations are toner particle size and shape, which directly influence print resolution, efficiency, and overall print quality.

Evolution of Toner Particle Size in Laser Printing

In the early stages of toner development, average particle sizes ranged from 14 to 16 micrometers. As printing technology evolved, particularly with the goal of achieving 600 dpi (dots per inch) resolution, manufacturers reduced the toner particle size to approximately 8 to 10 micrometers. Maintaining a tight and uniform particle size distribution remains essential for optimal print performance, toner flow, and device longevity.

Why Particle Shape Matters as Much as Size

While controlling particle size is crucial, particle shape plays an equally important role in laser printing performance:

-

Spherical toner particles promote consistent flow through the printer’s feed system.

-

They help deliver even toner application on paper, reducing streaking and improving clarity.

-

Smoother, rounder particles minimize mechanical wear on printer components.

For manufacturers, this means that analyzing both shape and size is key to maintaining high product quality and consistency across batches.

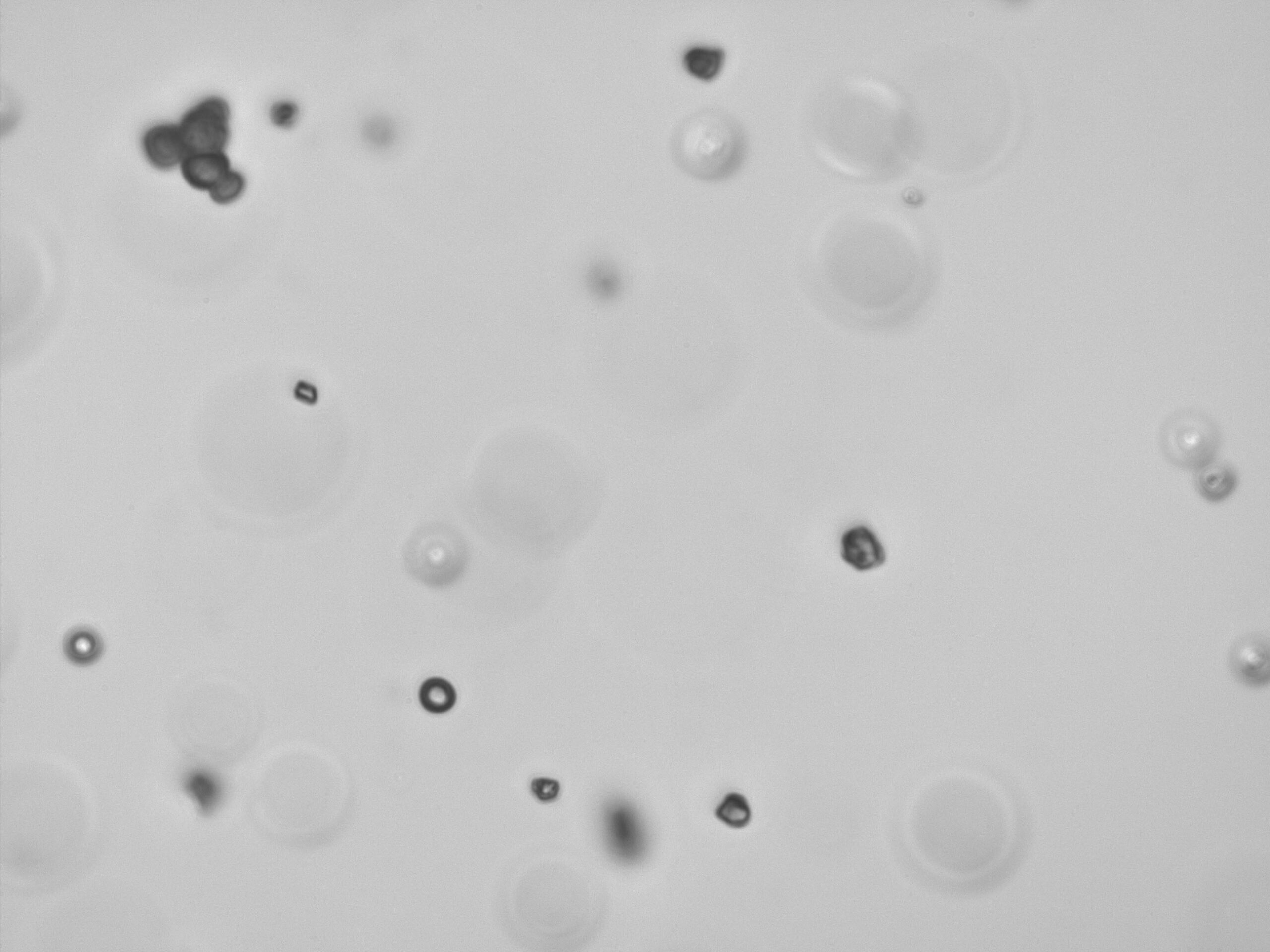

Advanced Particle Analysis Using Dynamic Imaging

Dynamic image analysis, such as that offered by instruments like the Pi Sentinel PRO or Particle Insight, provides accurate, real-time measurement of both toner size and shape characteristics.

According to Wikipedia, “Originally, the particle size of toners averaged 14–16 micrometers or greater. To improve image resolution, particle size was reduced, eventually reaching about 8–10 micrometers for 600 dots per inch resolution. Toner manufacturers maintain a quality control standard for particle size distribution in order to produce a powder suitable for use in their printers.”

Key Findings from a Recent Study

-

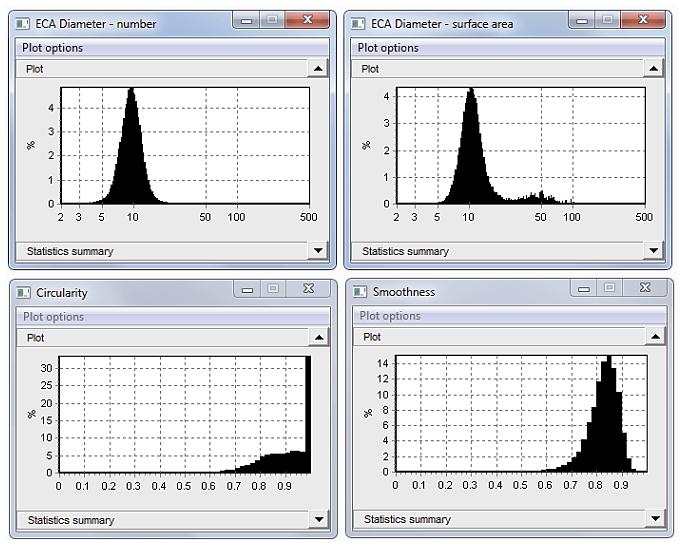

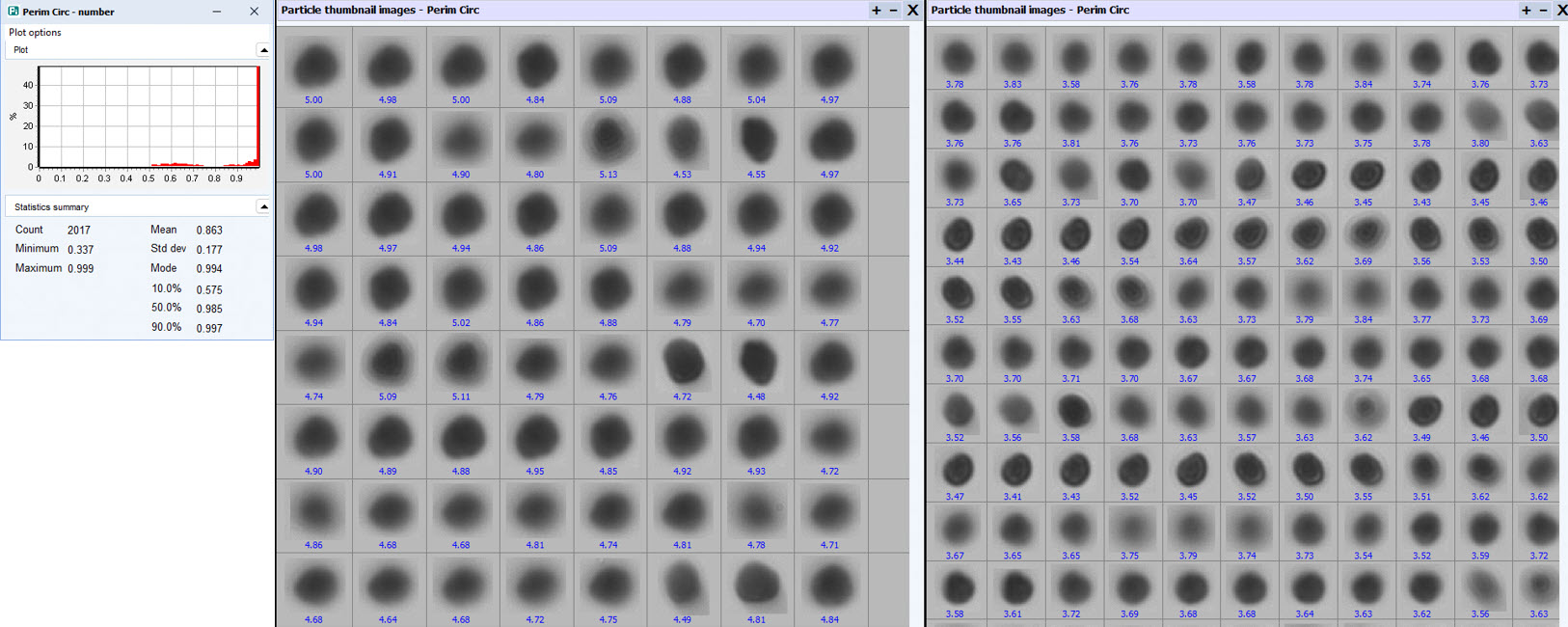

150,000 toner particles were analyzed.

-

Particle size distribution showed a near-Gaussian curve centered at 10 µm.

-

Minimum particle size was recorded at 2 µm.

-

Particles displayed high circularity and smoothness, indicating excellent flow properties.

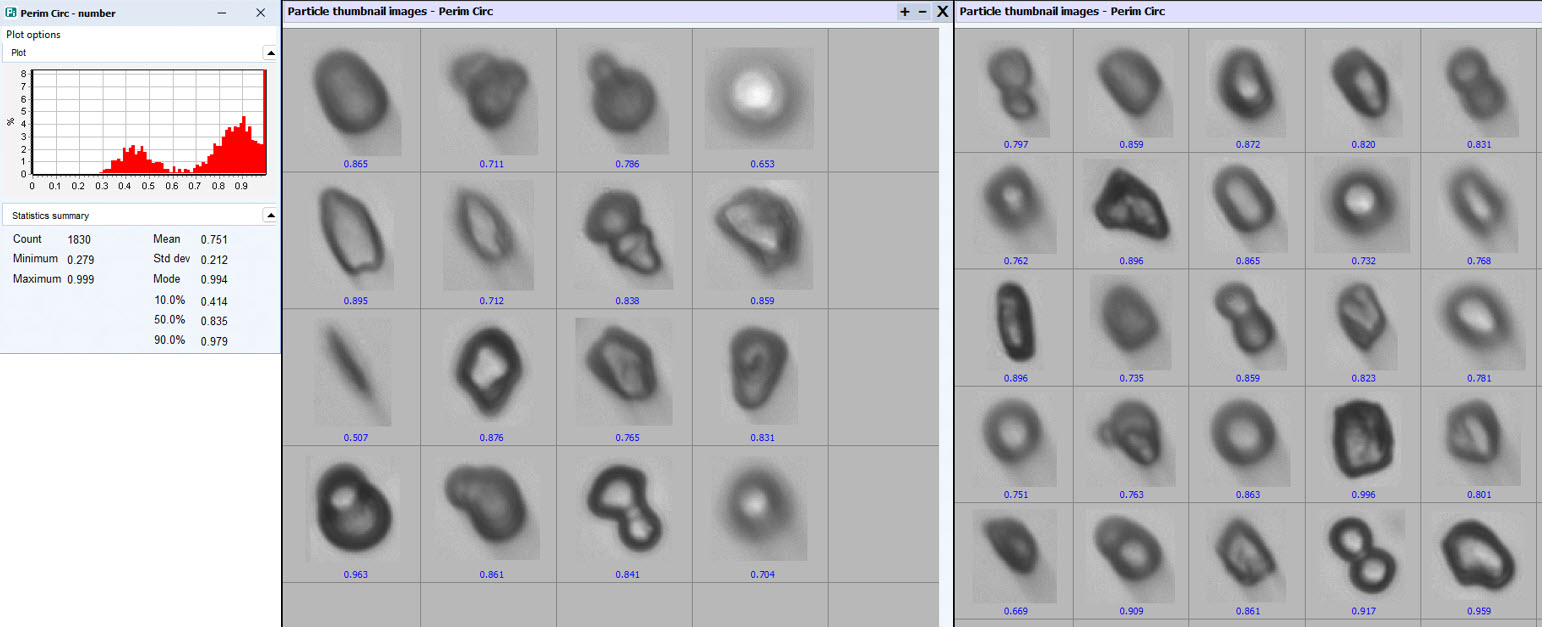

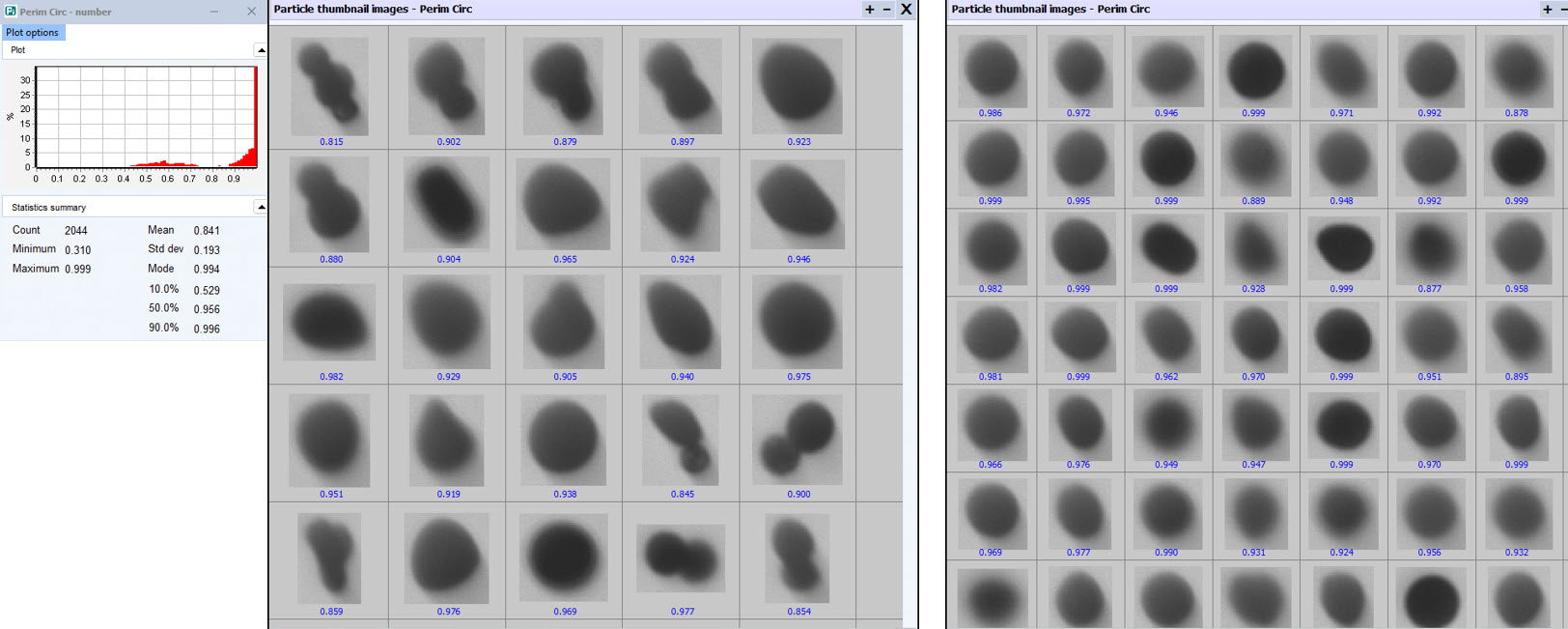

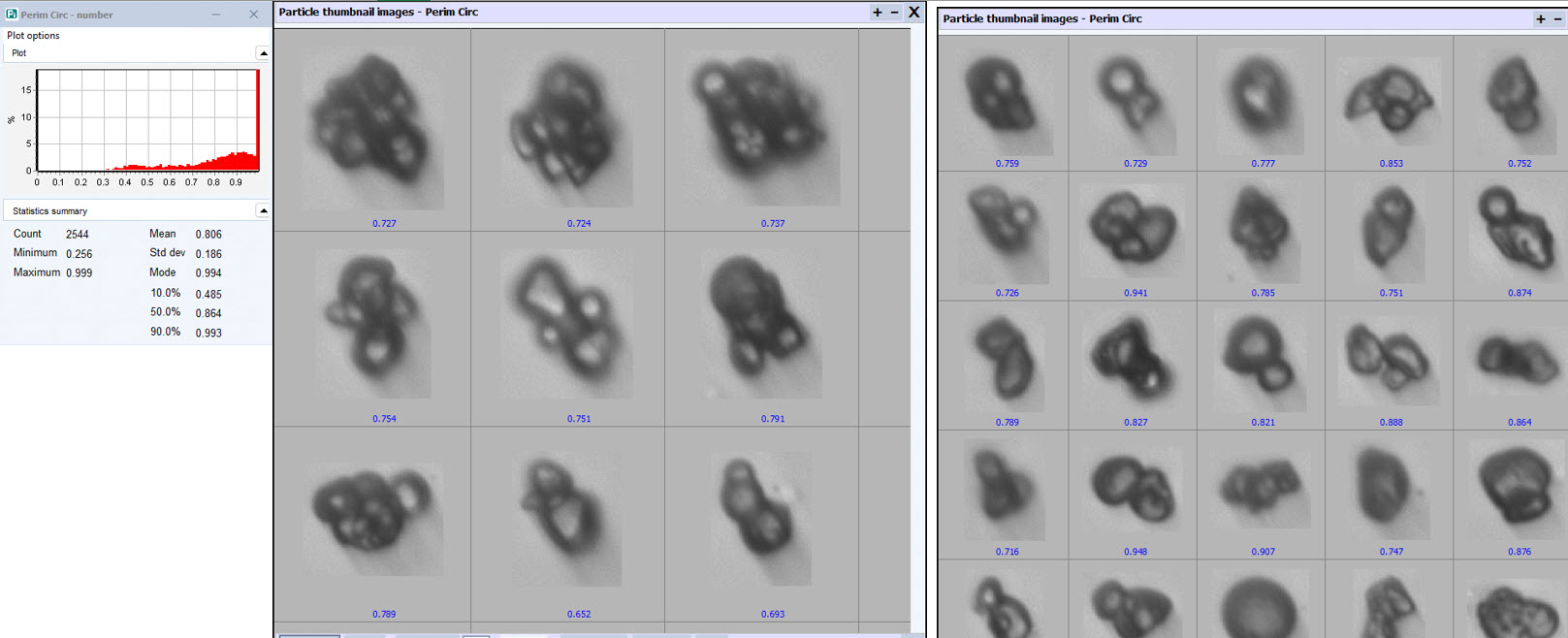

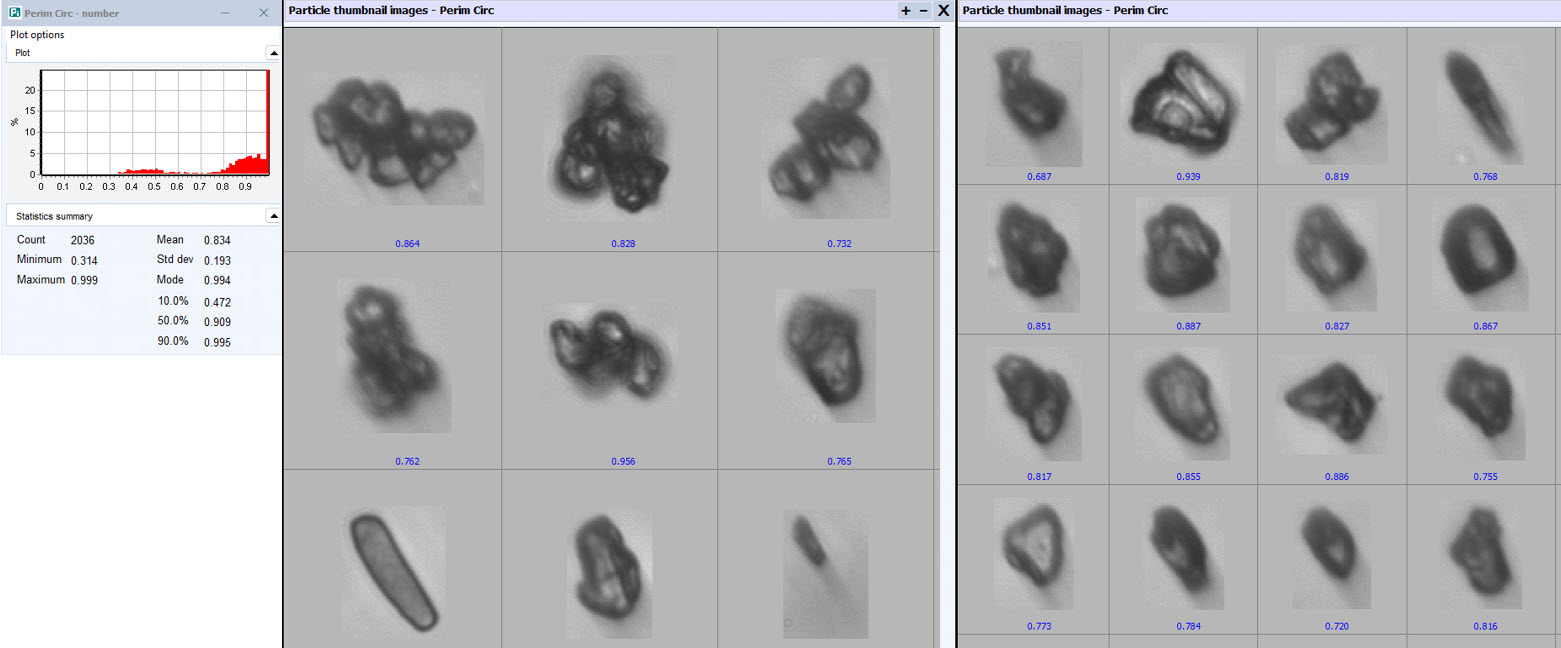

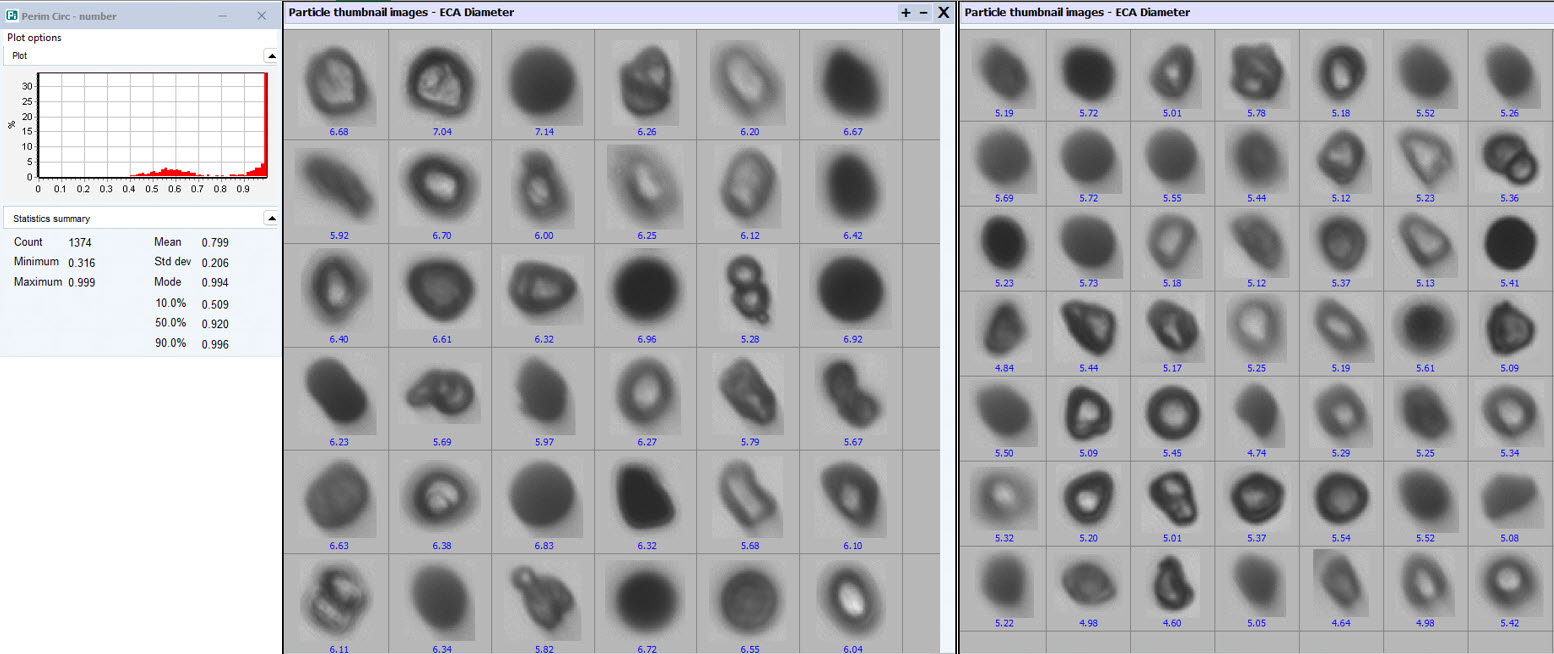

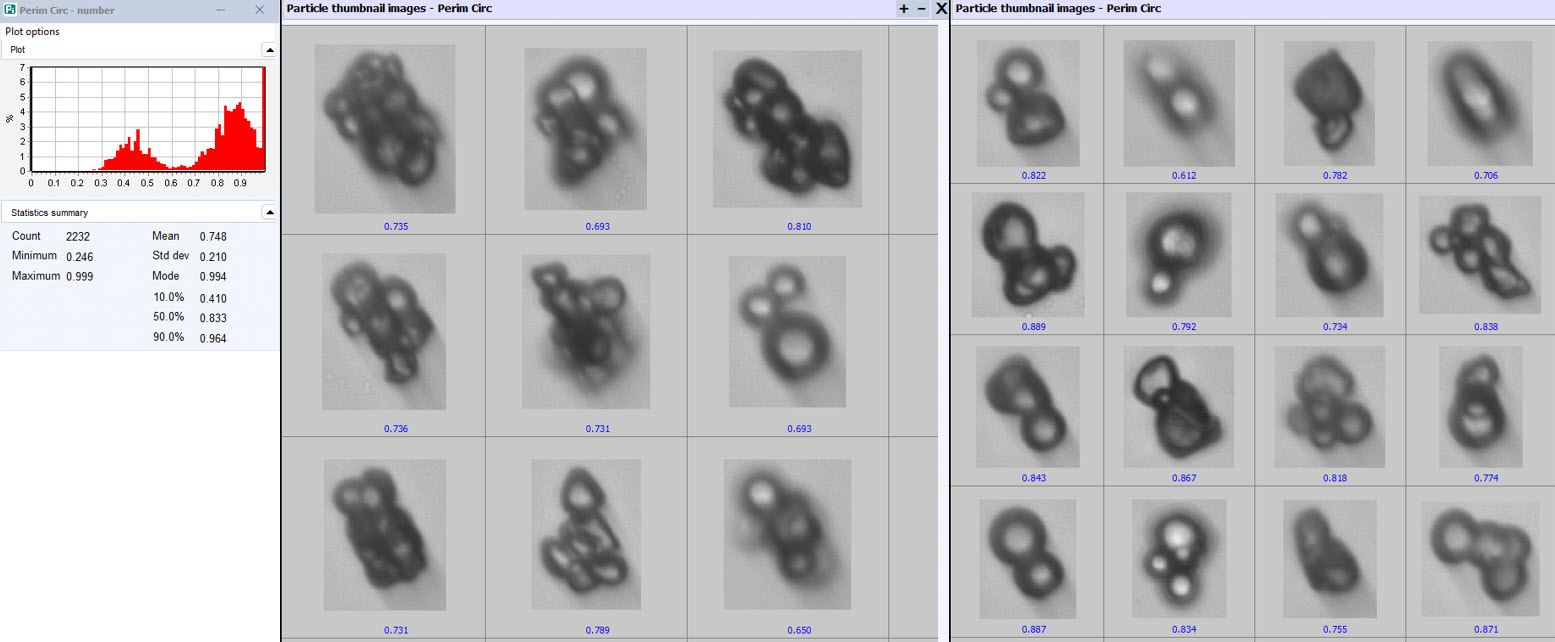

Metrics such as Equivalent Circular Area (ECA), Circularity, and Smoothness offer critical insight into toner morphology. These parameters help manufacturers detect agglomerates, irregular shapes, and outliers that may affect printing efficiency.

Visualizing Toner Distribution: Number vs. Volume Weighted Histograms

Both number-weighted and volume-weighted histograms were generated to depict the toner particle size distribution:

-

The number-weighted histogram reflects the particle count per size range.

-

The volume-weighted histogram—often used in laser diffraction analysis—is especially useful in identifying larger agglomerates that might affect toner behavior during printing.

By observing both, manufacturers can gain a comprehensive understanding of toner consistency.

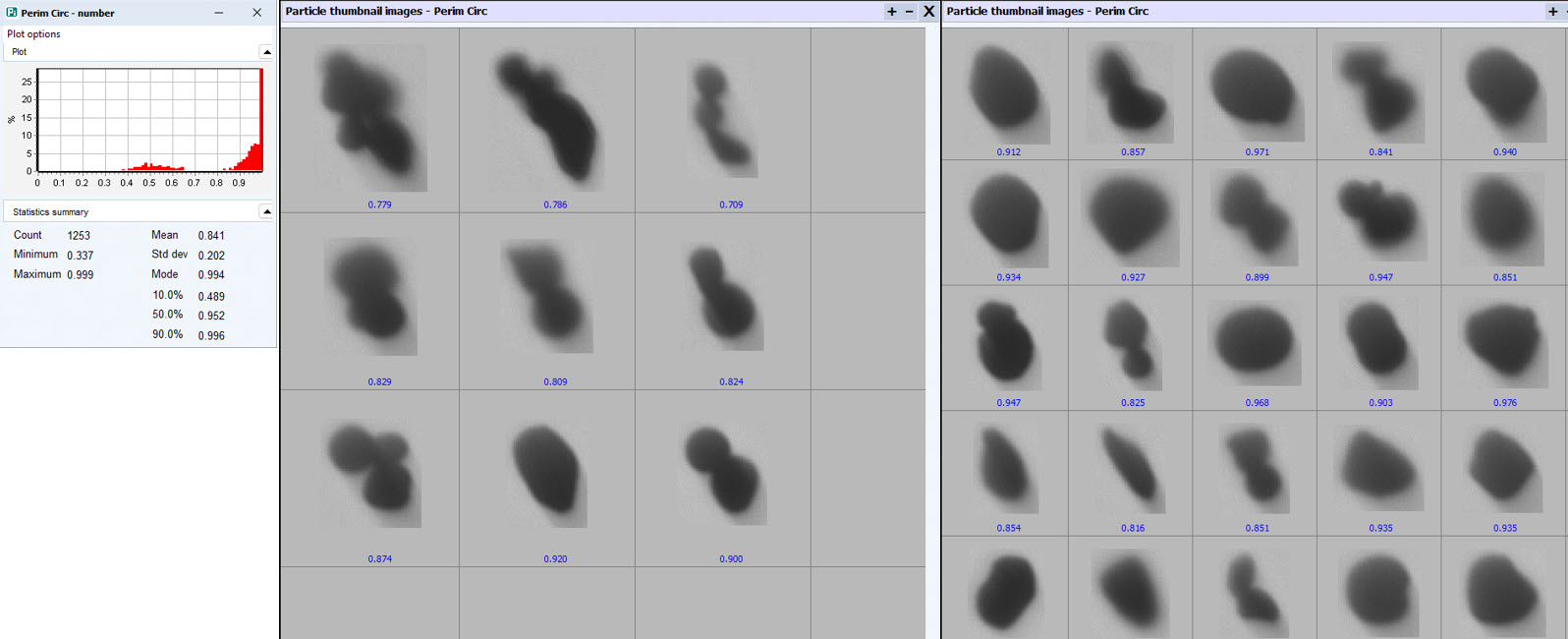

Additional analysis was done of numerous toner particles. The goal was to identify agglomerates. Below are results of the various toner particles analyzed.

Conclusion: Enhancing Print Quality Through Advanced Particle Analysis

In today’s competitive print technology market, precision control of toner particle characteristics is more important than ever. Dynamic image analysis enables toner producers to:

-

Maintain tight quality control.

-

Ensure batch-to-batch consistency.

-

Optimize toner formulations for high-resolution, efficient printing.

By focusing on both size and shape analysis, manufacturers can deliver superior toner performance, reduce printer maintenance issues, and meet growing demands for high-quality digital prints.