How Particle Shape Affects HPLC Column Packing and Performance | ParticleShape.com

When it comes to High Performance Liquid Chromatography (HPLC), most people focus on particle size. But ignoring particle shape can seriously hurt your column’s packing quality, flow consistency, and chromatographic performance.

In this article, we explain why particle shape matters for HPLC columns, how Dynamic Image Analysis solves shape problems, and what you can do to improve your column results.

Introduction

High Performance Liquid Chromatography (or High-Pressure Liquid Chromatography) is a separation technique used in many areas of analytical chemistry to separate, identify, and qualify various compounds in a specific solution. HPLC utilizes a column that holds chromatographic packing material that retains molecules as they are pumped through the column, the retention time being dependent on the packing material, the carrier liquid (solvent), and the specific type molecule. Each chemical species in the injected sample is most identified by UV and Mass Spec detection. Most traditional analytical HPLC packing materials have an average diameter of approximately 2 to 30 microns and are typically a silica-based or alumina-based material. The particle size of the packing material is usually measured using methods that assume all particles are uniformly spherical. This may not be the case, as in manufacture of the silica and bonding, fines and irregular shaped particles can be a percentage of the final product. As particle size decreases, the effect of fines and irregular shaped particles demands a greater degree of control on incoming quality of the silica material. Variation in particle shape can directly affect reproducible performance.

Read more about particle properties in our post:

👉 Basics of Particle Characterization

A column packed with uniform spherical beads is easier. to manufacture and yields consistent and uniform results.

The same column containing irregular particles and fines will present manufacturing challenges as well as end user concerns with respect to consistency.

Filling stage backpressure of the column can vary greatly depending on the shape of the HPLC particles. The flow of a packed HPLC sample column using perfectly spherical particles has a very predictable performance when used to separate molecules. In addition, the manufacturing of a column with only truly spherical particles would be predictably consistent.

However, in many situations, some of the particles used for HPLC column packing are irregular in shape. The percentage of irregular packing and fines can alter the consistency of performance of the column and make HPLC columns much more expensive to manufacture because of the additional care and expertise required in achieving consistency in production.

Possible downtime in production can result if incoming lots of materials contain varying percentages of irregular particles. Ideally, if there was a method for the packing material manufacturer to specify shape characteristics and for column manufacturers to inspect incoming materials against those specifications, manufacturing of HPLC columns would become more predictable, less costly and exhibit consistent performance. Recent advancements in Image Analysis could provide the answer. The analytical technique used in the experiment outlined in this application note is Dynamic Image Analysis. With Image Analysis, images are captured and analyzed as particles pass through a detection zone. ISO 13322-2 is used as the guideline for all Dynamic Image Analysis instruments available on the market today. The key benefit of using Image Analysis for HPLC column packing materials is to enable the identification and quantification of the different particle shapes present in incoming materials.

Experiment

Inconsistent packing pressures observed during the manufacture of a specific HPLC columns and a wide variation in their performance prompted the analysis of this sample. For this experiment, the Pi Sentinel PRO particle Shape Analyzer measured incoming HPLC materials used to pack Size Exclusion Chromatography columns. Proper sampling of the incoming materials was made to ensure a homogeneous subsample was taken. The sample was then suspended in water and analyzed. The Pi Sentinel PRO system recirculates the sample much like laser diffraction systems. All particles are measured and randomly oriented to measure all dimensions, not just two sides.

Results and Discussion

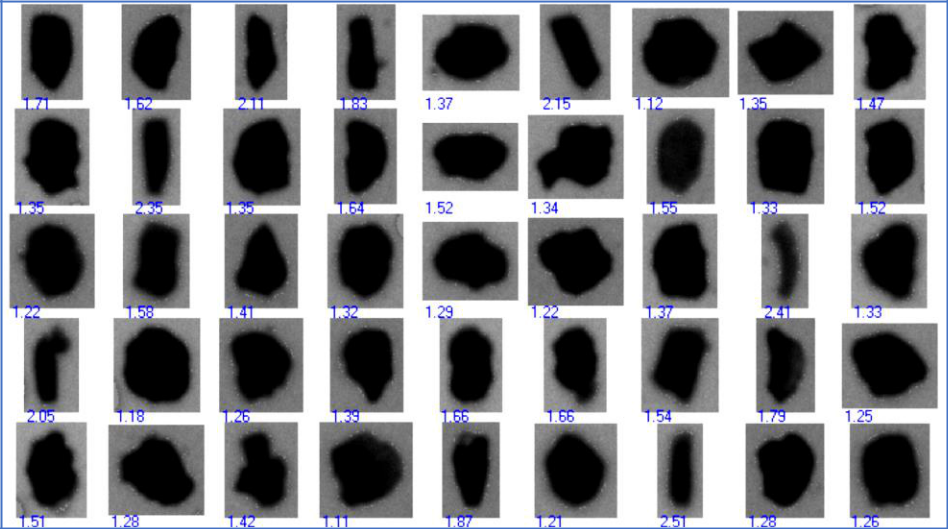

After analysis and a review of all particle thumbnail images, it was evident that this alumina sample had two distinct shape populations. One was rod-shape and the other had an aspect ratio near unity, but the particles were not round. Had the sample been analyzed using a sizing technique that assumes all particles to be spherical, these rod-like and irregular particles could not be differentiated.

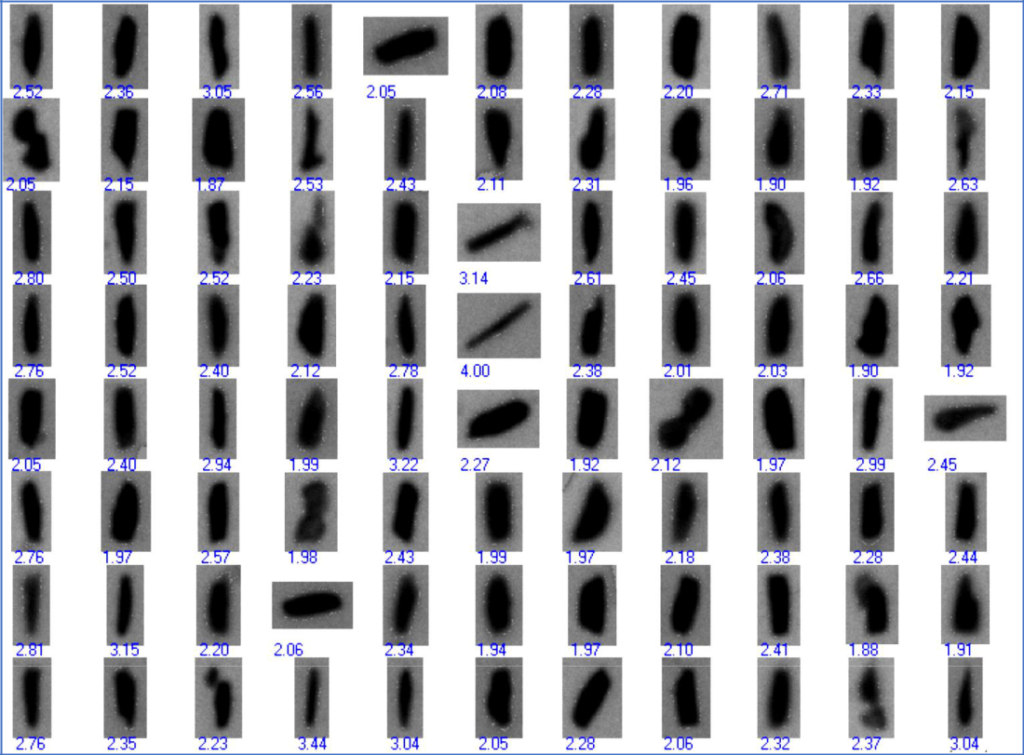

Random thumbnail images of the alumina sample from the 10,000 captured in just over one minute. The value under each thumbnail represents the Feret Aspect Ratio of each particle.

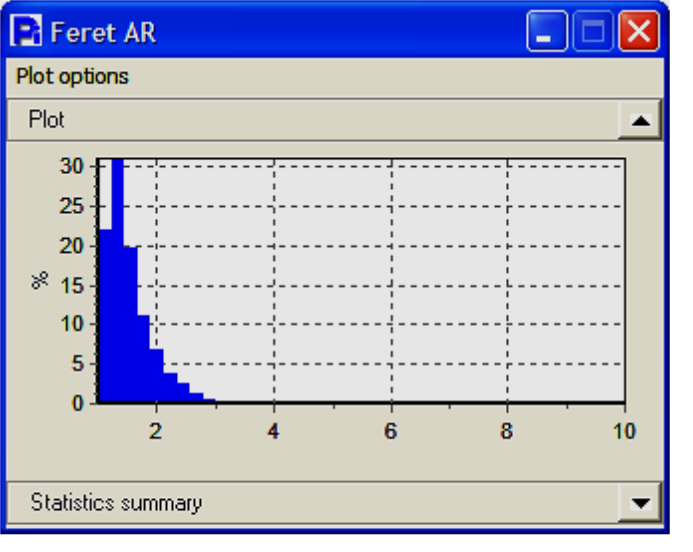

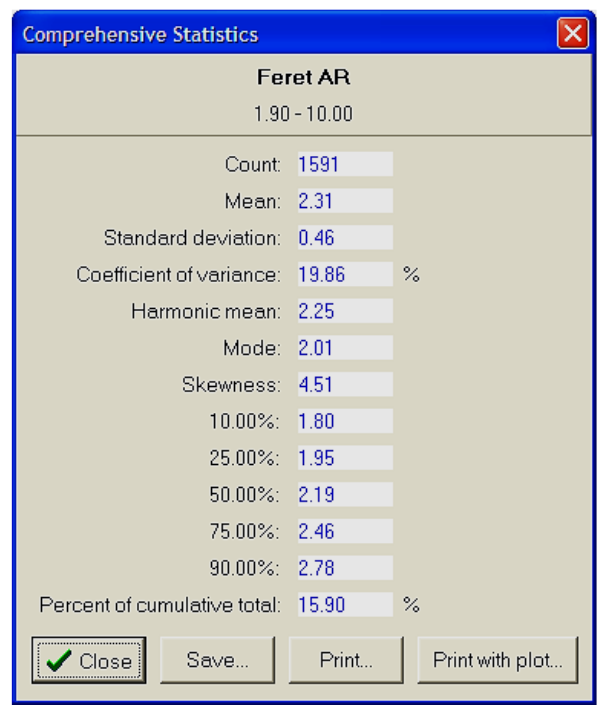

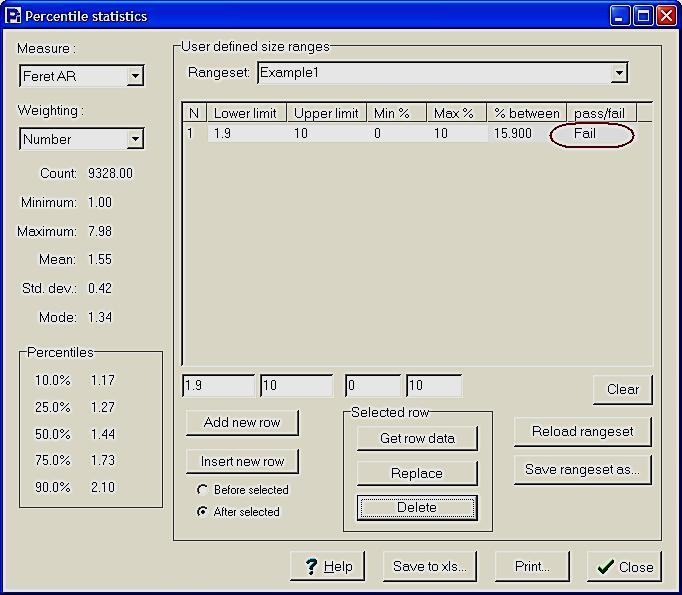

In developing a method for this sample, particles with an aspect ratio greater than 1.9 were considered to be rod-like and more likely to negatively impact the packing efficiency of the column. This aspect ratio value threshold was derived from sample lots that did and did not exhibit the problems previously described. As shown in the histogram and statistical data, the percentage of rod-like particles in this column packing material was 15.90% of the total distribution which, compared to the historical lot of good material, proved to be excessive for the particular application of the column.

Histogram of the alumina sample.

Comprehensive Statistics for the alumina sample

A review of the thumbnails for only those particles that have a Feret Aspect Ratio greater than 1.9 gives a better perspective on what these particles look like. With a method established to determine that the Feret Aspect Ratio of incoming alumina packing material had no more than 10% rod-like particles, the end-user was able to create a simple process control indicator with the Pi Sentinel PRO.

A sampling of the thumbnails of the 1,591 particles found to have an aspect ratio greater than 1.9.

Using the Percentile Statistics feature, incoming quality control can determine easily and quickly if a lot of material passes or fails the criteria established by management.

The Percentile Statistics feature enables you to see particle statistics and pass/fail criteria.

Conclusion

The Particle Insight series of products with its Dynamic Image Analysis technique can help reduce costs by finding HPLC packing material inconsistencies prior to reaching column manufacturing. The manufacturer is still responsible for determining the acceptable percentage of non-spherical particles for incoming materials. Once the manufacturer establishes incoming quality control criteria, the Insight instrument can be used as a Pass/Fail inspection tool to determine the percentage of spherical to non-spherical particles. Solving this potential problem early in the process improves production and helps to ensure consistent HPLC column quality and performance.

Want to know more about how shape influences overall particle behavior?

👉 Why Particle Shape Is Important