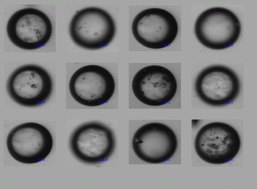

Key Insights into Water-Based Drilling Mud Through Image Analysis

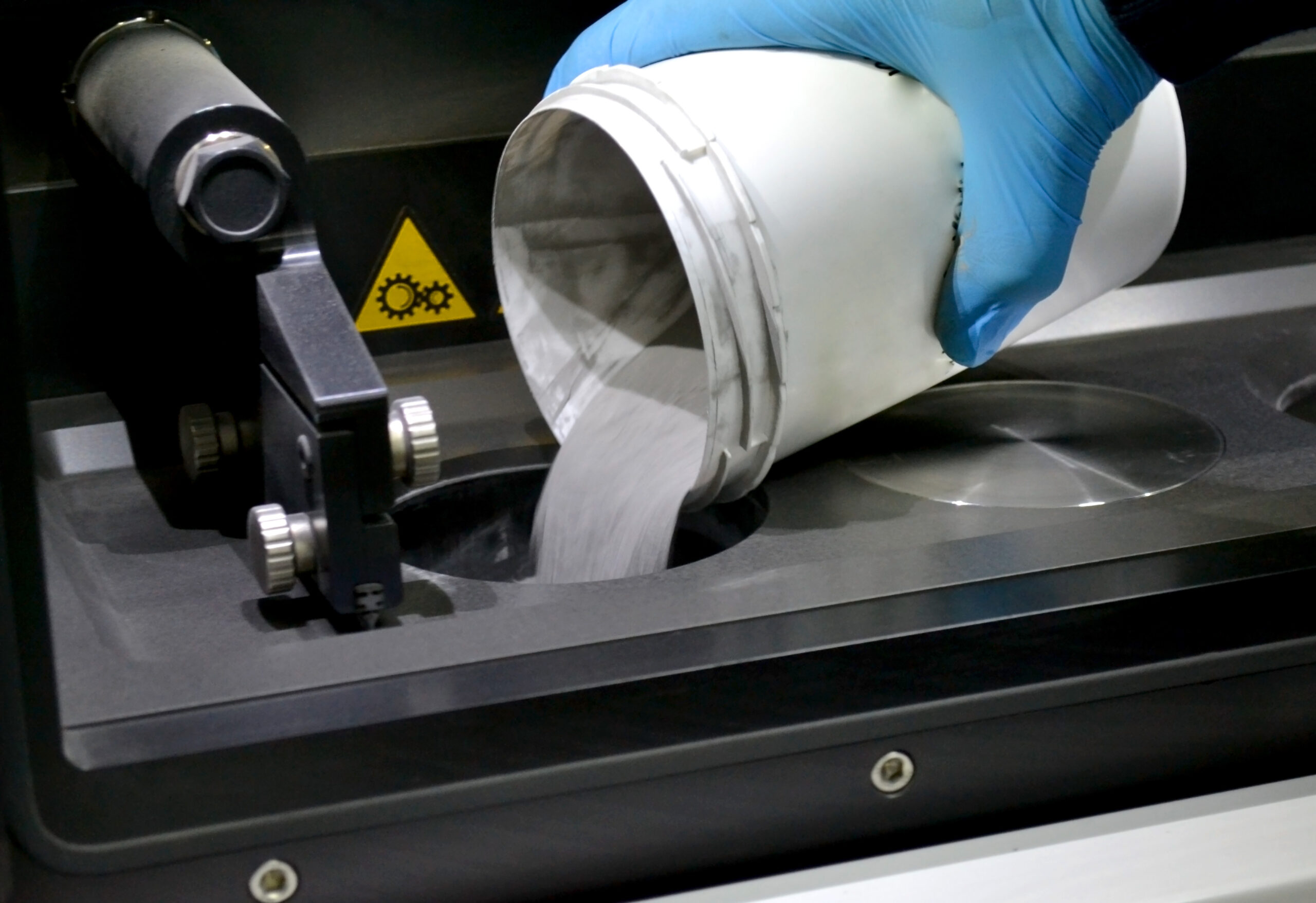

Water-based drilling muds are a critical component in the drilling industry. They offer a balance of efficiency, cost-effectiveness, and environmental safety. The physical characteristics of these muds, such as particle size and shape, play a pivotal role in their performance. Image analysis can help decipher the properties of these muds.