Particle Insight

Process Monitoring System

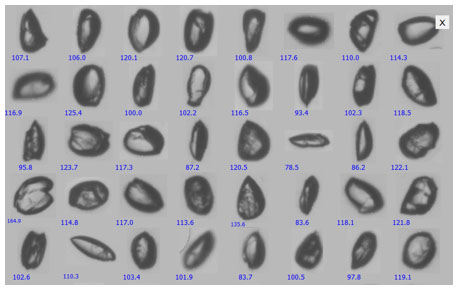

Dynamic Size and Shape Monitoring of Crystal Growth

Particle morphology of crystal growth provides important information regarding the physical shape properties of your API sample. By knowing true size and shape, with visual confirmation, the end user can determine when the crystallization process ends. Software assists with enabling downstream processes such as valve actuation and starting milling operations for Continuous Manufacturing processes for true on-line control.

The Particle Insight Process Monitoring System is a class-leading dynamic image analyzer that is ideal for applications where particle shape, not just the particle size, may be critical information for predicting raw material quality and to maintain a high level of process control. The Process Monitoring System is an on-line adaptation of a proven system that has been serving the Pharmaceutical market for well over 10 years.

Competitive systems offer qualitative information or cord length measurements. Particle Insight offers proper dispersion and high-quality imaging to give more than 31 shape measurements on each particle as well as concentration.