How the Raptor Dry Powder Module Reveals the Untold Story of Particle Shape

Introduction: Why Shape Is the New Size

When most scientists talk about starch powders, the conversation quickly turns to particle size. But if you’re only looking at size, you’re missing half the story.

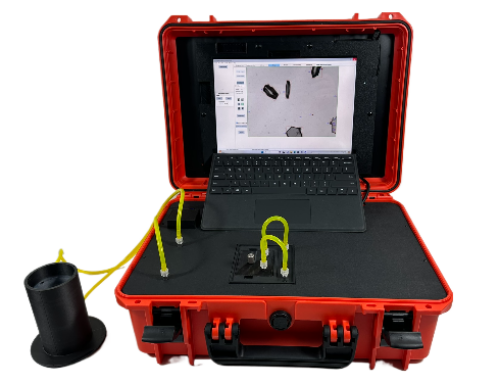

In industries ranging from food processing to pharmaceuticals, particle shape can significantly influence functionality—affecting everything from flowability and compressibility to reactivity and appearance. Enter Dynamic Image Analysis with the Raptor Dry Powder Module, a tool that makes exploring particle shape as easy as pressing “start.”

The Problem with Size-Only Analysis

Laser diffraction and sieving are classic go-to techniques for starch particle size analysis. While these methods are fast and useful, they make one major assumption: that all particles are spherical.

Spoiler alert—they’re not.

Starch particles are notoriously variable in shape depending on source (corn, potato, wheat, etc.), processing method, and intended application. Two starches may have the same D50 value, yet behave completely differently in a product.

Ignoring shape can lead to incorrect predictions of how a starch will perform in your process.

The Raptor Difference: Seeing Particles in a New Light

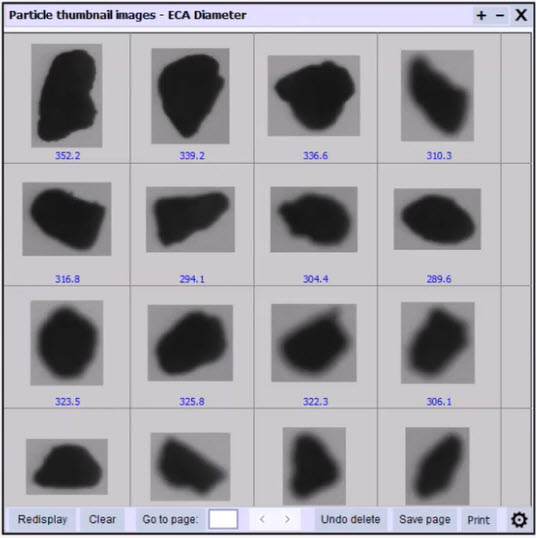

Starch Thumbnails. Very irregular particles will have poor flowability and compaction but have higher surface area

With the Raptor Dry Powder Module, you’re not just getting size metrics—you’re getting high-resolution thumbnail images and shape descriptors like:

-

Aspect Ratio

-

Circularity

-

Convexity

-

Elongation

These insights allow you to:

-

Detect unexpected particle types or contaminants

-

Understand the impact of milling or drying conditions

-

Tune particle morphology for desired product performance

And the best part? It’s incredibly user-friendly. As shown in the demo video, analyzing a starch powder sample takes just minutes.

Real-World Use Case: Starch in Food Applications

In the food industry, particle shape affects how starch hydrates, swells, and interacts with other ingredients. Irregular shapes can cause clumping or uneven texture. More uniform shapes lead to better mouthfeel and more consistent processing.

With the Raptor, QA teams can now monitor these parameters routinely, rather than relying on guesswork or occasional SEM snapshots.

▶️ Watch the video: How Easy It Is to Analyze Starch With the Raptor

Conclusion: Don’t Settle for Half the Picture

If you’re still only measuring size, it’s time to evolve.

The Raptor Dry Powder Module gives you a complete view of your powder’s morphology—automatically, efficiently, and with visual proof. This level of detail not only helps you make better decisions but can improve your product consistency, process control, and ultimately, customer satisfaction.

👉 Watch the video to see for yourself: Raptor + Starch Powder Demo