The Future of Hydraulic Oil Cleanliness Monitoring

Contaminant monitoring in hydraulic and lubrication systems is evolving. Traditional particle counting methods, such as Automated Particles Counters (light obscuration), have been the industry standard for decades, but they lack the ability to distinguish between contamination types or identify contamination sources. At-site oil testing is common practice. Testing is done to make fast decisions on the quality of machinery based on the particle count. Because of this, Automated Particle counters have been at the front line of testing with more sophisticated measurement equipment back in testing labs for more in-depth information on machinery health. The ability to have at-line testing with backup lab testing has become the norm for established quality processes to monitor machinery health. Unfortunately, Automated Particle Counters can only offer limited information on oil and machinery health. This is done reporting cleanliness codes such as the ISO 4406 and other similar reports.

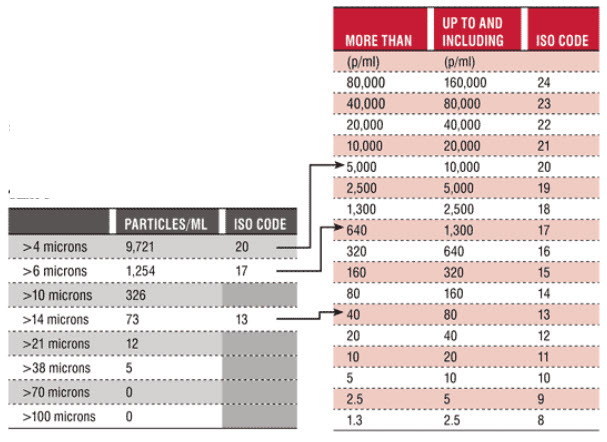

iso4406 reporting format

At-line testing using Automated Particle Counters requires a significant amount of expertise to prepare samples, run them, and analyze the results in a way to best monitor changes in fluid health and try to understand the source of the change. For example, an increase in particle count could be dangerous wear particles or water droplets both having different sources and different courses of action to intervene and prevent catastrophic failure. Particle sources could also be air bubbles which may not have any cause for concern. But, how can you make that determination at the point of testing? This is why samples are then sent to a lab for further testing which takes time (days or weeks) where machinery can be sitting idle waiting for results or can be damaged further if operated while waiting for lab test results. Both causing a waste in money.

This limitation has led to the adoption of Dynamic Image Analysis (DIA), an advanced technology that provides both quantitative and qualitative contamination insights.

With the introduction of ISO 21018-1, the industry now recognizes alternative methods for contamination monitoring, opening the door for Dynamic Imaging to become the new standard for hydraulic fluid cleanliness assessment at the source. Besides offering standardized reporting codes, Dynamic Imaging also offers thumbnail images of all measured particles greater than 1micron as objective evidence. This objective evidence enables operators to make accurate fast decisions for corrective action.

Why Traditional Methods Fall Short

Light obscuration particle counting (calibrated to ISO 11171) has long been the default method for hydraulic oil contamination monitoring. However, it has several shortcomings:

- Inability to Differentiate Contaminants – Light blockage methods only count particles but cannot determine if they are metal debris, fibers, water droplets, or gels.

- False Positives – Air bubbles and soft contaminants can interfere with light extinction measurements, leading to inaccurate contamination levels.

- Limited Particle Size Range – Many traditional particle counters struggle with very small (<4µm) and very large (>100µm) particles.

- Clogging – Traditional light obscuration systems can become easily clogged with large particles requiring them to have internal filters that prevent cloging but will also prevent detection of large particles.

- Accuracy Concerns – Traditional particle counters will mathematically adjust the particle count based on the assumption of coincidence. This is the assumption that based on size of the particles, there will be some that statistically be at the same place at the same time and may be counted as a larger particle than it really is.

- Limited Versatility – Traditional particle counters are single-pass detection systems. Once the sample is measured, it is dropped into waste where recovering the sample for further analysis is difficult.

- No Visual Evidence – Without images, maintenance teams lack direct evidence of the contamination type and source.

The Dynamic Imaging Advantage

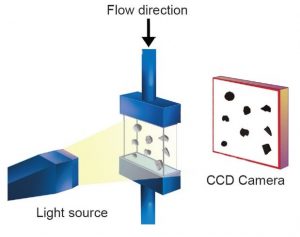

Figure showing the principle of operation behind dynamic image analysis

Dynamic Image Analysis (DIA) overcomes these limitations by providing a clear, visual representation of fluid contamination. Instead of just counting particles, DIA captures high-resolution images of each particle, allowing for shape analysis and contamination source identification.

Key Benefits of Dynamic Imaging for Contamination Monitoring:

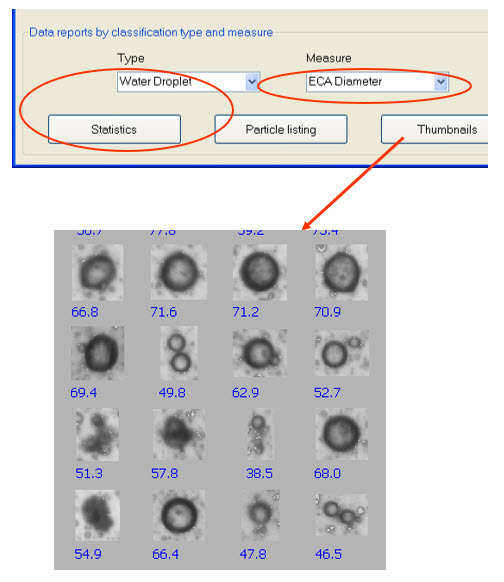

✅ At-Line and Real-Time Contamination Identification – Portable high-resolution thumbnail images of contaminants allow users to distinguish between wear debris, dirt, fibers, gels, and water droplets or air bubbles and take immediate corrective action based on the source of the contamination. A picture is worth 1000 words. No expert needed! No guessing!

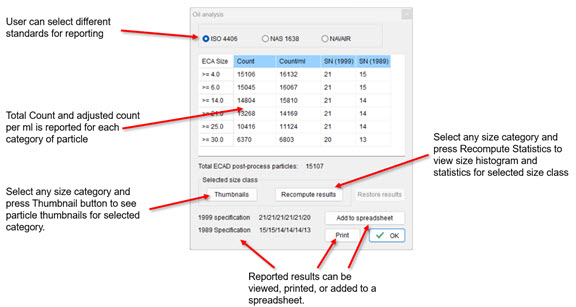

✅ Same Reporting Codes – Just as APC’s, Dynamic Imaging also offers all the reporting codes with a twist. The user can “SEE” the particles in each class allowing them to identify the source of contamination.

ISO 4406 reporting codes

✅ Same Counting and Concentration – Just as APC’s, Dynamic Imaging is a number-based analysis system where it can give total count as well as concentration. However, due to its ability to differentiate particle types by size and shape, Dynamic Imaging can also give count and concentration for different classes of particles. Particle classes can be size classes (>4microns, etc) or shape classes (Cutting Wear, etc). This allows users to obtain more detailed information on trends in particle count by type. Something APC’s cannot do.

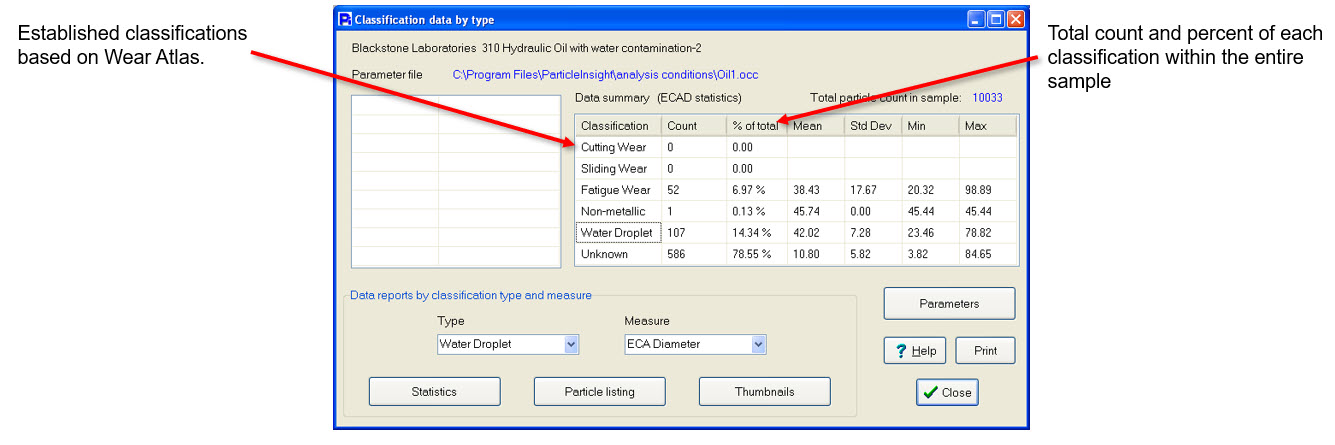

✅ Classify Particles – ALL measured particles (particles greater than 1 micron and smaller than 300 microns) can be classified by the standard Noria Wear Atlas based classifications.

Particles can be classified by established wear classes or can be customized.

Select one class of particle, and you can then see all the particle thumbnails for that class. This objective evidence allows users to identify the source of the contamination and take immediate and accurate corrective action without guessing.

Particles can be classified by established wear classes or can be customized.

✅ Better Decision-Making for Maintenance – Maintenance teams can analyze the root cause of contamination rather than just responding to particle count trends.

✅ Reduction in False Positives – By identifying and eliminating / ignoring misclassification of bubbles and soft contaminants, DIA improves contamination accuracy. No coincidence correction required in dynamic imaging. All particles between 1 and 300 microns are measured and thumbnail images are saved.

✅ Compliance with ISO 21018-1 – Recognized as a valid alternative method, making it a future-proof contamination monitoring solution.

✅ Easy Adaptability – Same sample preparation as that of Automated Particle Counters.

✅ Versatile Sampling – Similar to APC’s, can run in single-pass mode, but can also be run in re-circulating mode, or with sterile syringes both offering to keep your initial sample for future testing and reference.

✅ Calibration Standards – Recognized calibration standards available similar to APC standards.

How Dynamic Imaging Transforms Fluid Cleanliness Management

| Feature | Dynamic Imaging (ISO 21018-1) | Light Obscuration (ISO 11171) |

|---|---|---|

| Particle Identification | Yes, with thumbnail images | No, only counts |

| Shape Analysis | Yes, to differentiate particles | No |

| Contaminant Source ID | Yes, with objective evidence images | No |

| False Positive Reduction | Yes, filters out air bubbles | No, cannot differentiate |

| Applicable to All Fluids | Yes, can operate with limited opaque fluids. | Limited to clear fluids |

| ISO Standard Compliance | ISO 21018-1 | ISO 11171 |

The Market Shift: Why Industries are Adopting DIA

Industries that rely on hydraulic systems, fuel quality, and lubrication maintenance are moving toward Dynamic Imaging due to its ability to provide deeper insights into contamination issues at the point of testing with an abundance of data enabling fast and accurate decision making. Key sectors benefiting from DIA technology include:

🚛 Fuel and Lubrication Monitoring – Ensuring compliance with the same cleanliness standards used for APC’s and detecting contamination sources in real-time reducing equipment down-time and equipment damage caused by waiting for slow lab results.

🏭 Manufacturing & Industrial Equipment – Reducing unexpected failures through precise contamination tracking. Track not only particle count but classes of particles. An increase in particle count could be as insignificant as air bubbles caused by poor sample prep or as urgent as an increase in fatigue ware or water droplets in oil.

🛢 Hydraulic Systems & Heavy Machinery – Improving system efficiency and longevity by identifying contaminants before they cause wear.

🔬 Laboratory & R&D Applications – Enhancing contamination studies with detailed particle characterization.

The Future of Fluid Cleanliness: A New Industry Standard

With ISO 21018-1 validating alternative monitoring technologies, Dynamic Imaging is positioned to become the new industry standard. By providing deeper contamination insights, improved accuracy, and real-time imaging, DIA is revolutionizing the way industries monitor and manage fluid cleanliness.

🚀 The future of contamination monitoring is here! Explore how Dynamic Imaging can transform your fluid cleanliness strategy.

📩 Contact us or visit www.ParticleShape.com to learn more about how DIA technology is setting a new standard for contamination monitoring.

📩 Want to run a free sample? Contact us or visit www.ParticleShape.com

🔗 Check out our Hydraulic Oil Testing Guide

🚀Other articles to view….

View our Blog post on Particulates in Fuel and Lubricating Oils here.