Understanding Particulate Contamination in Hydraulic Oil: A Comprehensive Guide

The Importance of Hydraulic Oil Cleanliness

Hydraulic systems are the backbone of industrial machinery, ensuring efficient operation, lubrication, and cooling. However, particulate contamination is one of the leading causes of system failures, unplanned downtime, and costly repairs. Effective contamination monitoring and control strategies are essential to extending equipment life and maintaining optimal performance.

What is Particulate Contamination?

Particulate contamination in hydraulic oil refers to solid particles suspended in the fluid, which can originate from various sources, including:

- Wear debris from pumps, valves, and actuators

- External contamination from dust, dirt, or moisture ingress

- Oil degradation products such as varnish and sludge

- Improper filtration or maintenance practices

Even microscopic particles can cause damage by blocking small passages, eroding components, and reducing lubrication efficiency.

Industry Standards for Hydraulic Oil Cleanliness

To ensure reliability, various ISO standards define methods for monitoring particulate contamination in hydraulic fluids:

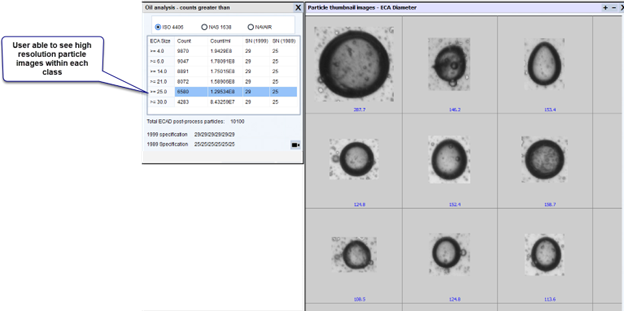

- ISO 4406: Specifies a cleanliness code based on particle counts at different size ranges.

- ISO 11171: Standardizes calibration of automatic particle counters using light extinction.

- ISO 21018-1: Introduces alternative methods, including Dynamic Image Analysis, for contamination monitoring when traditional methods are insufficient.

Common Methods for Contamination Monitoring

Several techniques are used to analyze particulate contamination in hydraulic oils, each with its advantages and limitations.

1. Light Obscuration (ISO 11171)

✅ Common and widely accepted ✅ Automated and fast particle counting ❌ Does not differentiate between contamination types ❌ Struggles with water droplets, air bubbles, or soft contaminants

2. Microscopic Analysis (ISO 4407)

✅ Provides direct visual confirmation of particles ✅ Can classify wear debris, fibers, and dirt ❌ Time-consuming and labor-intensive ❌ Requires expert interpretation

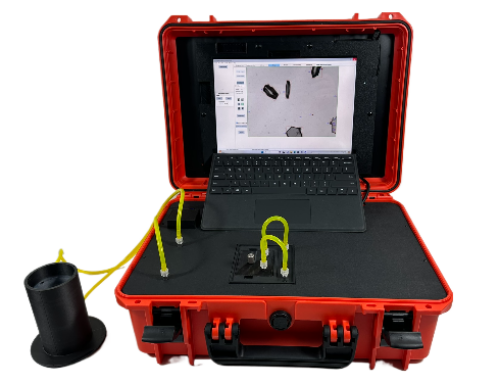

3. Dynamic Image Analysis (ISO 21018-1 Compliant)

✅ Captures high-resolution images of contaminants ✅ Provides shape-based classification to identify wear particles, fibers, and gels ✅ Reduces false positives from air bubbles or water droplets ✅ Supports proactive maintenance by identifying contamination sources ❌ Newer technology—adoption is still growing

Best Practices for Hydraulic Oil Contamination Control

To maintain optimal oil cleanliness and extend system longevity, follow these best practices:

1. Regular Oil Analysis

Routine oil testing allows for early detection of contamination before it leads to severe wear or system failure.

2. Proper Filtration

Use high-efficiency filters and regularly replace them to prevent contaminant buildup.

3. Contamination Source Identification

Understanding where contaminants come from (e.g., metal wear, seal degradation, external dust) enables targeted maintenance strategies.

4. Compliance with Industry Standards

Following ISO 4406 cleanliness codes ensures that hydraulic systems meet the required contamination limits for different applications.

Figure 5 Oil wear reporting to meet requirements as well as thumbnail images for any selected class as objective evidence.

Conclusion

Particulate contamination in hydraulic oil is a silent killer of system reliability. By implementing effective monitoring techniques, following industry standards, and employing best practices, industries can significantly reduce maintenance costs, prevent failures, and improve overall efficiency.

With the introduction of ISO 21018-1, newer methods like Dynamic Image Analysis are providing greater insights into contamination sources, helping industries shift from reactive to proactive maintenance strategies.

🚀 Want to learn more about hydraulic oil contamination monitoring? Stay ahead by exploring advanced techniques today!

📩 Want to run a free sample? Contact us or visit www.ParticleShape.com

Other articles to view….

View our Blog post on Particulates in Fuel and Lubricating Oils here.