The Significance of Particle Shape

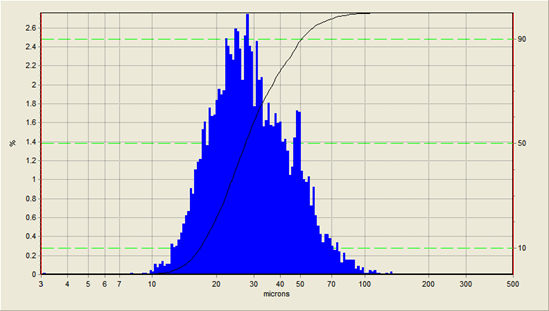

Investigating raw materials for particle size distribution is a very common practice in many industries. Particle size measures have become the standard inspection criteria for incoming materials, and outgoing products that we all use every day. Particle size is the main way powders and other granular materials are quantized. But, how is “particle size” defined?

Because most powder granules in industry are irregular in shape, this question does not have a simple answer. Industry, as a general rule, avoids the issue by determining a single size, or “diameter”, for each particle, under the implicit assumption that the particles are round. Even when it is known that the grains are not spherical, it is common practice to use a measurement technique that reports a single size figure for each particle.

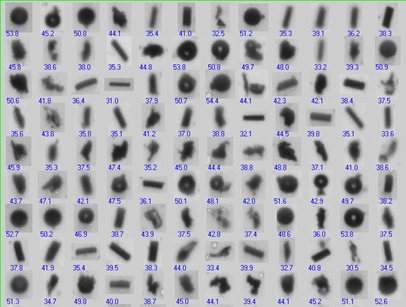

Different kinds of instrumentation will often report a different size number for the same particle, especially if it has an irregular shape. The more serious problem is that with many non-spherical materials, single size number statistics are not sufficient to determine how the substance will perform. Single size number statistics cannot adequately characterize the product. This is especially true if a sample contains more than one kind or classification of particle, as in the example below.

All these particles – spheres, irregular shapes, and fibers – report a single ECA diameter of about 40 μm. |

Assuming that all particles are spherical can impact your process because the size statistics mix the different shapes together. Assuming that all particles are spherical can impact your process because the size statistics mix the different shapes together. |

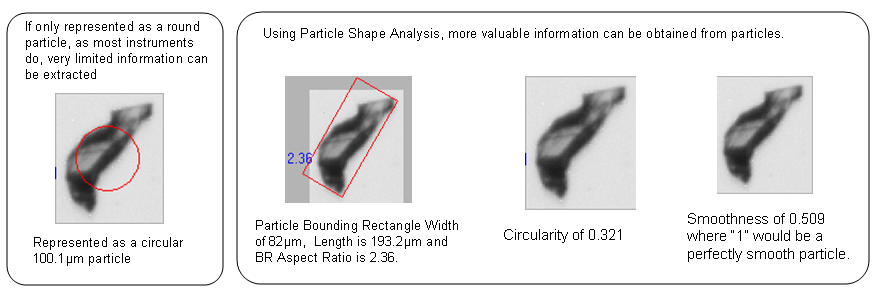

When powder particles are elongated or fibrous it is clear that length and width measures are needed, at a minimum. But even with low aspect ratios, meaning particles are not elongated, they can still be irregular, and in order to predict performance it may be necessary to obtain statistics on the minimum and maximum diameters (Feret length and width), and on how much they deviate from being spherical.

“Circularity” is a measure of roundness of the particle silhouette, and by inference the degree of sphericity, in the range 0 to 1.0. It is computed from the area and perimeter of the actual particle silhouette. It is also possible to put a number on surface smoothness, from the shape of the particle outline.

“Circularity” is a measure of roundness of the particle silhouette, and by inference the degree of sphericity, in the range 0 to 1.0. It is computed from the area and perimeter of the actual particle silhouette. It is also possible to put a number on surface smoothness, from the shape of the particle outline.

Another measure, “convexity”, tells us how “regular” the shape is from a larger perspective; that is, to what extent it is free of indentations and protrusions. All these measures are possible and meaningful even for shapes that are approximately round.

Aspect ratio, circularity and smoothness give us information about non-spherical objects:

In certain industries such as abrasives, it is sometimes important to garner additional shape information; number of polygonal sides and the interior angles for instance.

With rectangular or fiber samples, a single size number is far from sufficient. We need to know the distribution of widths present, or of the lengths, or both, or statistics on the aspect ratios. Surface smoothness may also be important in these cases.

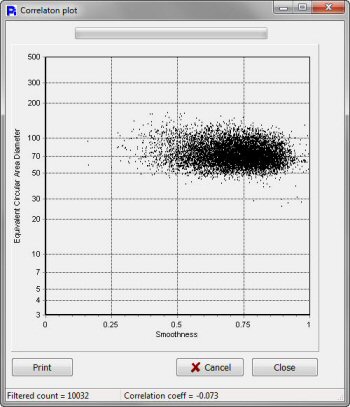

A powerful feature of shape analysis is being able to correlate shape statistics with size statistics, to see how shape changes with size. This takes the form of a scatter diagram, with one point for every particle.

[details]

[details]

Another powerful feature is the ability to define subcategories within a sample, based on size and shape simultaneously, and derive separate statistics for each class of particle. [details]