Presented at Reliable Plant 2025 by Peter Bouza, Vision Analytical

🛢️ Outgrowing the Limits of ISO 11171

For decades, ISO 11171 has served as the benchmark for particle counting in hydraulic fluids and lubricants. Its method—Light Obscuration (LO)—relies on measuring the size of particles by how much light they block. While effective in many contexts, this technique falls short in modern reliability and contamination analysis where shape and type of particles offer critical insight into wear, failure modes, and contamination sources.

As equipment tolerances tighten and uptime expectations grow, industry professionals are demanding more from their particle monitoring tools.

📘 Introducing ISO 21018: A Modern Approach

ISO 21018 (Part 1) is a new international standard that addresses this gap. It acknowledges that traditional LO-based particle counting cannot differentiate between air bubbles, water droplets, fibers, or metallic debris—all of which may register the same size but have vastly different consequences for machinery.

ISO 21018 opens the door to alternative, image-based methods like Dynamic Image Analysis (DIA), which offer:

-

Real images of particles

-

Size + shape metrics

-

Thumbnail records for traceability

-

Better identification of root causes

This is a major advancement in how we understand fluid cleanliness—and it’s especially timely for lubrication professionals.

🎤 Watch the Presentation: ISO 21018 at Reliable Plant 2025

In June 2025, I had the opportunity to present this topic at the Reliable Plant Conference. The presentation covered:

-

A critical comparison between ISO 11171 and ISO 21018

-

Real-world examples of Dynamic Image Analysis in lubrication

-

A look at how Vision Analytical’s Raptor system aligns with ISO 21018 standards

If you missed the talk, I’ve made it available on YouTube here:

📸 What is Dynamic Image Analysis (DIA)?

Dynamic Image Analysis is a powerful tool that captures high-speed images of flowing particles, allowing for detailed characterization in real time. Unlike LO systems, DIA doesn’t guess shape from shadows—it shows the actual particle geometry.

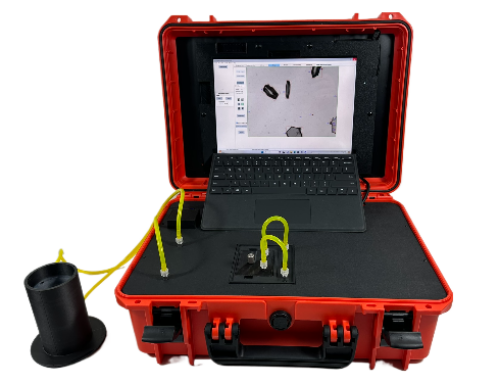

With systems like the Raptor analyzer, users can:

-

Count and classify particles based on shape (not just size)

-

View particle thumbnails for every sample

-

Reduce misidentification from bubbles or water

-

Meet ISO 21018’s criteria for image-based particle monitoring

DIA doesn’t just report data—it tells a story about what’s happening in your system.

📊 ISO 21018 vs ISO 11171: A Visual Comparison

To help make the distinction clearer, we’ve created a 1-page infographic comparing ISO 11171 and ISO 21018:

-

Measurement Technique

-

Data Output

-

Use Case Relevance

-

Strengths & Limitations

💾 [Download the infographic here — coming soon!]

🚀 Ready to Modernize Your Particle Analysis?

If you’re still relying solely on ISO 11171-compliant LO systems, now is the time to consider more advanced tools. Whether you’re managing industrial gearboxes, turbines, hydraulic systems, or labs testing lubricant health, Dynamic Imaging aligns with the future of particle monitoring.

📞 Want to learn more about Raptor and ISO 21018?

Reach out for a demo or technical brief at www.particleshape.com