INTRODUCTION

System Description

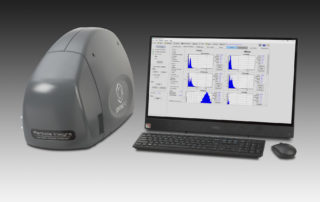

The PI SENTINEL Shape Module (PiSM) is a Dynamic Image Analyzer that measures particles ranging from 1 to 300 μm in diameter with a standard configuration. Optional optical configurations are available for an expanded size range. The PI SENTINEL Shape Module can acquire statistically valid measurements of a sample in a very short amount of time; a capability that is essential for quality control purposes in many manufacturing processes. It differs from many microscopy-based systems in that it emphasizes speed and statistical assurance.

PI SENTINEL Shape Module Advantages

- Real-time results – Shape analysis & display shown in real-time as images are captured, providing instant results the moment analysis begins.

- Obtain meaningful results – Offering 30 size / shape measures. The ability to correlate multiple shape measures gives unprecedented power to single out key particle shapes of interest.

- Multi-Run sample trending – Ability to track size and shape changes over user defined time intervals, for statistical process monitoring and control

- Real Time backup – Data mirroring feature to store all analysis data in multiple locations simultaneously offering a real-time backup of data as well as giving lab managers the ability to review results remotely.

- Statistical assurance – The recirculating pump and unique optics assures statistical accuracy without the need of costly sheath fluids or complex optical components.

- Data reporting flexibility – Data for a sample is saved in the sample file, and may be printed or exported to Microsoft XLS (Excel) format. A data summary from each of several runs may be combined into one worksheet.

- Simulated sieve data – Size distributions may be reported as fractional parts on a set of sieves, allowing comparison to real sieve data.

- Rare event detection – Particle Thumbnail feature extracts individual particle silhouettes from captured images that meet user-defined shape parameters.

- Security and Regulatory Compliance – Compliant with the FDA 21 CFR Part 11 regulations with multiple levels of security and robust audit log that tracks all security-related actions.

- Post Run Processing – Advanced feature that captures all measured particles and saves them for additional viewing and processing after the analysis.

- Auto-Classification – Feature allows the analysis of sub-components within the same mixed particle at the click of one button.

Specifications

Size Range: 1 µm to 300 µm depending on particle density with standard optics configuration. Optional lenses/cells available to expand size ranges: 10 µm to 800 µm and 100 µm to 2500 µm.

Image rate: Up to 30 frames per second in high resolution mode. Higher speeds available at lower resolution settings.

Shape Models:

- Circle Measures:

Equivalent circular area diameter, Equivalent circular perimeter diameter, Bounding circle diameter, Mean diameter, Circularity, Smoothness, Compactness - Ellipse Measures:

Equivalent elliptical area width, length, Bounding ellipse width, Length, Elliptical aspect ratio, Ellipticity - Rectangle Measures:

Bounding rectangle length, Width, Bounding rectangle aspect ratio; Rectangularity - Polygon Measures:

Polygon order, Interior angles, Convexity - Fiber Measures:

Fiber length, Width, Fiber aspect ratio, Fiber curl - Irregular Measures:

Ferret length, Width, Ferret aspect ratio, Smoothness - Optical Measures:

Opacity and White fraction

Fluid compatibility: Compatible with most common suspension fluids (aqueous and organic). Please refer to chemical resistance table available from manufacturer.

System volume: PI SENTINEL Shape Module allows for different sample volumes.

Voltage: 100 – 240 VAC

Frequency: 50/60 Hz

Temperature: 10 to 45 °C for operation. -10 to 55 °C for storing or shipping

Humidity: 20 to 80% relative, without condensation

Width: 25.4 cm (10 in.)

Height: 38.1 cm (15 in.)

Depth: 63.5 cm (25 in.)

Weight: 13.2 kg (29 lbs.)

Computer minimum Requirement:

- 2 GHz CPU speed or better

- 1GB B RAM (minimum)

- 60 GB hard drive

- Writable CD or DVD drive

- USB interface (2 USB3 connectors)

- 24” LED Touchscreen

ANALYZER OVERVIEW

Principle of Operation

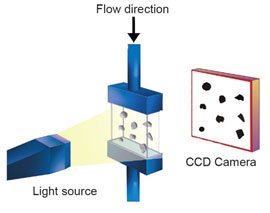

Particles flow through a view cell. An illumination source on one side of the flow cell shines light through the cell to a lens and digital camera on the other side. The camera records dark silhouettes of the particles and sends the images to the PC computer in grayscale format.

Software characterizes each particle based on the size and shape of the particle shadows using a pre-selected shape model that is appropriate for the kind of particles being analyzed.

In run mode, the camera images are analyzed as they come in, and the software accumulates statistics on the results of each image analysis. Data on individual particles can be saved while running. The statistical plots and values are shown on-screen while running and updated as the analysis is occurring. At the end of a run the accumulated particle statistics are available for display, printing, or export to Microsoft XLS format.

The image rate of the camera itself is 30 images per second. The software attempts to capture and analyze every camera image but may run at a slower rate depending on the number and type of measures selected and particle density. Higher frame rates can be achieved if the resolution setting of the camera is reduced.

In addition to the normal number histograms, the software generates surface area-weighted and volume-weighted histograms for some of the shape models, making certain assumptions about particle size and shape in the third (unseen) dimension. The recirculating fluidic system presents particles for analysis in a random orientation. This is critical to ensure all dimensions of the particles in question are being measured, not just two dimensions.

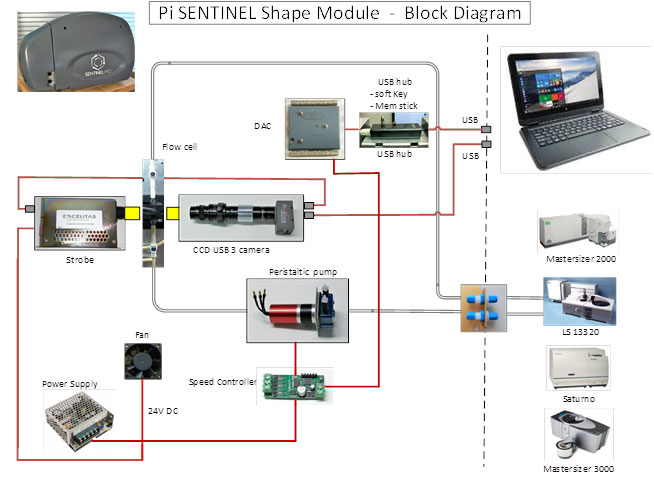

System Overview

The PI SENTINEL Shape Module can be adapted as an accessory to several particle sizing instruments in the market. The module has a circulation peristaltic pump and can be setup as a stand-alone system. However, it can be setup with flexible external pumping option. Particles suspended in fluid coming from an external source, flow through the Quartz Flow Cell by activating the circulation pump via software. The speed of the pump can also be adjusted via software on a Speed Controller PCB associated with it.

An illumination source Strobe module on one side of the flow cell shines light through the cell to

a lens and Digital Camera on the other side. The camera records dark silhouettes of the particles and sends the images to the PC computer via USB3 serial connection in grayscale format.

The application software processes the data and provide the shape information about the particles. A 24V DC Power Supply provides the required voltage for the module operation.