Quantity of Fines Could Be More Important Than Particle Size Distribution

Silicon carbide equivalent circular area diameter distribution analysis of two (2) samples F8 & F6 are shown below with their respective statics.

Comparing these analyses suggests that sample F6 has a mean size 44% larger than sample F8.

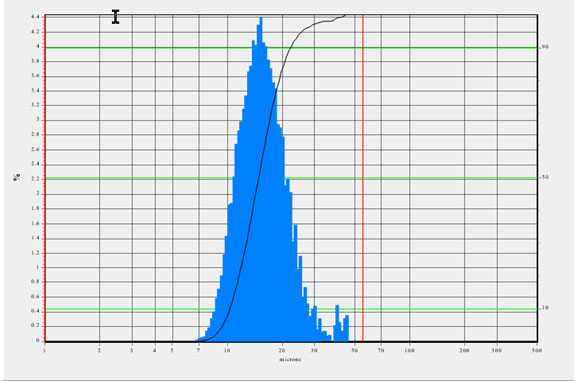

Silicon Carbide F8 Volume Distribution

ECA Diameter – Volume: 1.0 – 55.06 microns

Total count 20,057

Mean 11.4 microns

10.00% 7.8 microns

25.00% 9.0 microns

50.00% 10.6 microns

75.00% 12.6 microns

90.00% 15.0 microns

Silicon Carbide F6 Volume Distribution

ECA Diameter – Volume: 1.0 – 55.06 microns

Total count 19,919

Mean 16.4 microns

10.00% 10.6 microns

25.00% 12.5 microns

50.00% 15.2 microns

75.00% 18.8 microns

90.00% 22.9 microns

The Vision Analytical Sentinel Pro Particle Insight allows one to select any particle size range of a sample and immediately identify statistics across this selected size range. We can then isolate/identify each particle above 30 microns for each sample. We can observe that sample F8 has only three (3) particles greater than 30 microns while sample F6 has 36 such particles. Also sample F8 particles above 30 microns are near 50 microns in size which will skew it volumetric particle size distribution accordingly.

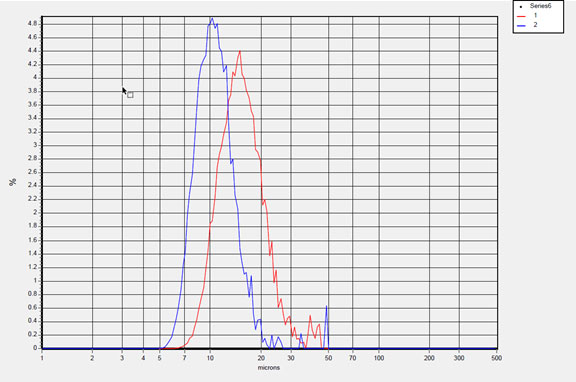

The built-in overlay capabilities of the Sentinel Pro can illustrate these difference as shown below. Note that no particles can be seen below 5 microns when using the volumetric display.

Silicon Carbide F8 vs F6 Volume Overlay

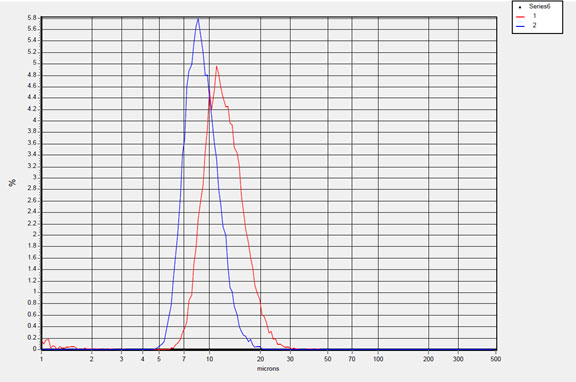

The Vision Analytical Sentinel Pro Particle Insight has an additional feature beyond typical laser analysis. If one is careful to select a sample concentration so every image contains a single particle, one can look at the number of particles for a given particle size, much as a particle counter. The number distribution removes the bias toward larger particle volume contributions to the distribution analysis. Smaller particles then have the same weight as larger particles and we can now see the quantity of particles at any sizes range. The Sentinel Pro can show statistical differences between these samples by number, even for all captured 30 shapes.

Below is an overlay of these same samples by a number distribution.

Note that the particles above 30 microns “disappear” because a single large 50 micron particle in sample F6 is an insignificant percentage of the total number of measured particles.

Note one more observation: It appears sample F8 fines below 5 microns is different than sample F6.

Silicon Carbide F8 vs F6 Number Overlay

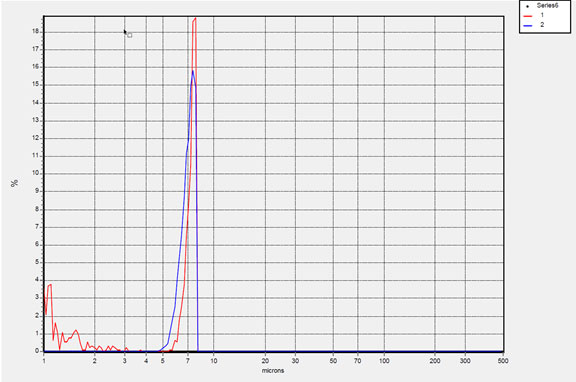

The Sentinel Pro software allows one to select any ECA diameter range, calculate new statistics across this range and present data and graphs for this new focus analysis. Selecting an ECA diameter from 1.0 – 5.0 microns should show the significance of the fines between these two samples

Below is an overlay of these samples by number of particles below 5 microns.

Silicon Carbide F8 vs F6 Number Overlay Below 5 microns

Here are the captured statistics of each sample below 5 microns:

Silicon Carbide F8 Volume Distribution Below 5 microns

ECA Diameter – Number: 1.0 – 5.0 microns

Total count 25

Mean 2.9 microns

10.00% 1.1 microns

25.00% 1.3 microns

50.00% 1.6 microns

75.00% 4.8 microns

90.00% 5.0 microns

Silicon Carbide F6 Volume Distribution Below 5 microns

ECA Diameter – Number: 1.0 – 5.0 microns

Total count 256

Mean 1.4 microns

10.00% 1.0 microns

25.00% 1.1 microns

50.00% 1.2 microns

75.00% 1.5 microns

90.00% 1.9 microns

Conclusions:

- Sample F6 has 10 times the number of fines below 5 microns

- Most of sample F6 fines are significantly smaller than sample F8

- Sample F6’s volumetric mean is 44% larger than sample F8, yet contains much more fines

- Resample F8 to see if you can repeat the measurement of any particles above 30 microns

- Sample F8 could produce a tighter, more uniform particle size distribution with less fines

- Sample F8 could be the superior product; how do these samples perform in the process? Different??