The First Truly Portable Dry Powder Analyzer for Pharma, Cement, and Manufacturing Industries

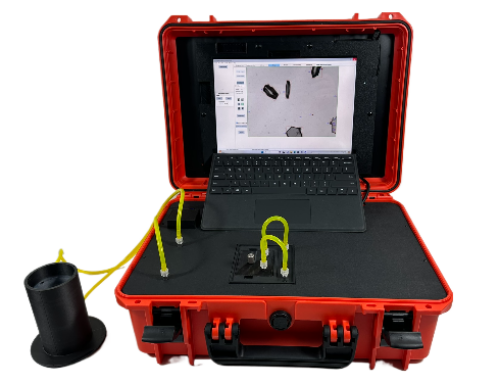

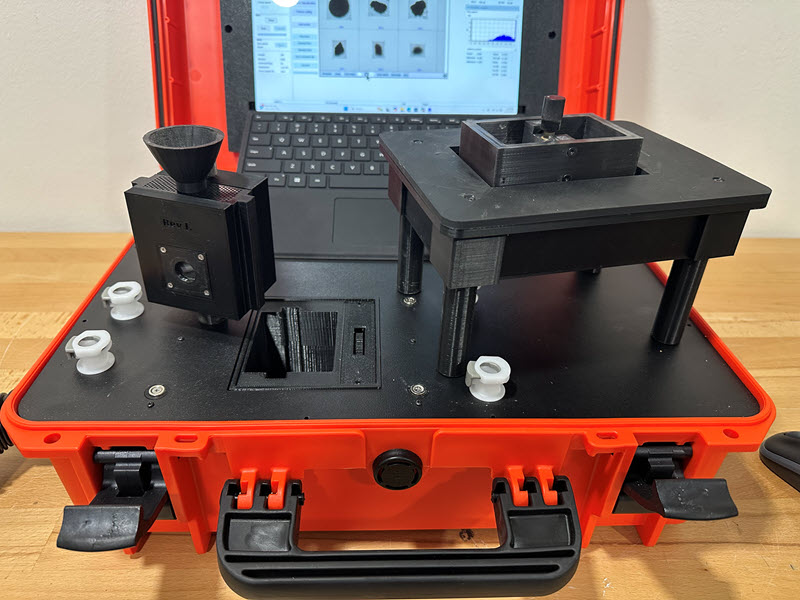

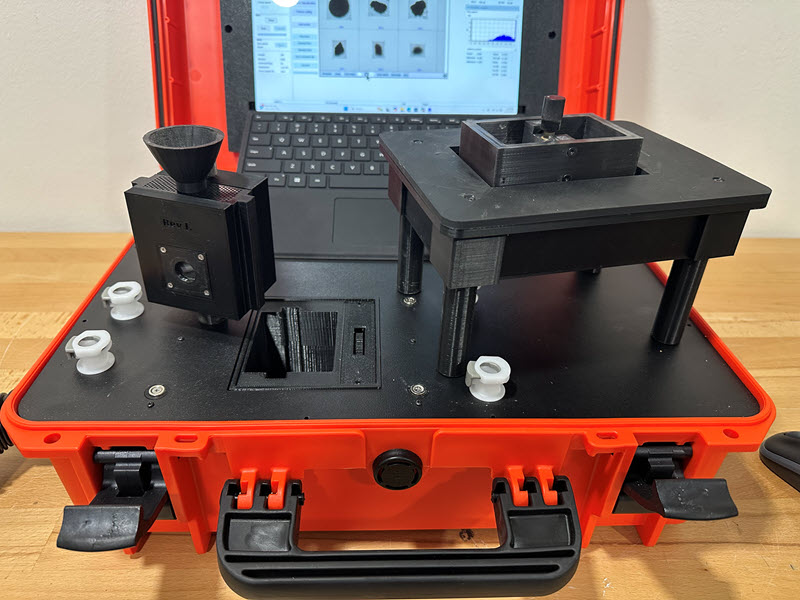

Dry Powder Module on Raptor Portable particle size and shape analyzer.

In industries where dry powder analysis plays a critical role — like pharmaceuticals, cement manufacturing, additive manufacturing, and many more — precision, efficiency, and flexibility are essential.

Yet for too long, dry powder systems have been large, stationary, and difficult to integrate into dynamic work environments.

Today, we’re proud to announce a breakthrough innovation:

The Raptor Portable Dry Powder Analyzer — the first dry powder system designed specifically to be portable without sacrificing performance.

Why Portability Matters in Dry Powder Analysis

Traditional dry powder systems require powders to be transported to the analysis lab — a process that introduces potential for:

- Sample contamination

- Loss of critical time

- Decreased efficiency in production workflows

The Raptor Portable Dry Powder Analyzer changes the game by enabling engineers, operators, and quality control specialists to bring advanced dry powder analysis directly to the point of need — whether that’s on a production floor, a clean room, or in field applications.

Key Features of the Raptor Portable Dry Powder Analyzer

✅ Truly Portable — lightweight, compact design that fits into existing workflows without disruption.

✅ High-Precision Measurement — leveraging dynamic image analysis to deliver particle size and shape information with exceptional accuracy.

✅ User-Friendly Interface & Tools — intuitive dashboard with tools allowing for FAST decision-making in the field. No experts required.

✅ Versatile Application — engineered to perform reliably across a wide range of powders: pharmaceutical excipients, cement powders, specialty chemicals, and more.

✅ Rugged Design — built for mobility while maintaining the robustness needed for industrial environments.

✅ Thumbnail Images — with thumbnail images as objective evidence of what’s in your sample, you don’t need to be an expert to SEE what’s happening in your process and make a decision in the field.

Dry Powder Module on Raptor Portable particle size and shape analyzer.

Industries That Will Benefit

🔬 Pharmaceutical Industry

Perform real-time analysis of active ingredients and excipients without leaving the cleanroom or production site.

🏗️ Cement and Construction Materials

Monitor particle size distribution and material consistency on-site to ensure product quality and optimize formulation.

🧪 Chemical Manufacturing

Analyze specialty powders without interrupting manufacturing flow or compromising sample integrity.

⚙️ Advanced Manufacturing & 3D Printing

Optimize powder bed fusion and other additive manufacturing processes by ensuring the right particle characteristics are maintained.

Setting a New Standard

With the Raptor Portable Dry Powder Analyzer, we are redefining what’s possible in powder analysis.

It is not just a tool — it’s a catalyst for faster insights, higher-quality production, and more agile operations.

Whether you’re working in pharmaceutical quality control, building infrastructure with the highest-grade cement, or advancing cutting-edge manufacturing techniques, the Raptor Portable Dry Powder Analyzer gives you the power to analyze faster, smarter, and on the move.

Learn More

View a live demonstration here on YouTube

For more information on the Pi Raptor Portable, click here.

Learn more about the Particle Insight Raptor from some of our Channel Partners…

Meritics Limited – UK – Particle Insight Raptor Portable

Related Press Release from Azo Networks.. Raptor DPM: The First Portable Powder Particle Analyzer

🚀 The future of particle size and shape is here! Explore how Dynamic Imaging can transform the way you test materials.

📩 Contact us or visit www.ParticleShape.com to learn more about how DIA technology is setting a new standard for contamination monitoring.

📩 Want to run a free sample? Contact us or visit www.ParticleShape.com

🚀Other articles to view….