High Resolution Particle Size Goes to the Streets

In today’s fast-paced industries, using and understanding particle size and shape is crucial for maintaining product quality and optimizing processes. The Particle Insight Raptor Portable emerges as a groundbreaking solution, offering unparalleled precision and portability for comprehensive particle analysis.

The Way Particle Size Once Was

Traditionally, particle size and other analytical instrumentation would be located in a laboratory somewhere in a building or in a centralized location. This was done for several reasons.

- Precision particle size equipment is typically very sensitive to temperature changes. Temperature variation can alter alignment in the case of some techniques and can also alter the measurement readings due to temperature changes in the suspension fluids.

- Also, in the case of Laser Diffraction that requires constant automatic alignment of the laser, being a portable system would be very difficult to maintain alignment of such sensitive lasers and detectors in the field. This can result in erroneous size results.

- Attempts to make portable particle analysis equipment have generally failed because of the above-mentioned reasons. Also because of these mentioned reasons, instruments that are field-based tend to have much lower resolution than lab-based instrumentation to compensate for temperature and vibration impact. The result is that such low resolution for traditional field-based particle analysis equipment cannot capture changes in your sample or process the same way lab-based equipment can.

As a result, when samples are taken in the field, decisions cannot be made until the samples are sent to the in-house or outside lab, processed, and data is reported. Results are then sent back and analyzed by an expert to determine if the process is within specification or out of specification. This can take as little as a day but in most cases, it will take many days during which time decisions cannot be made and money is lost waiting for data results.

Portability Meets Laboratory-Grade Accuracy

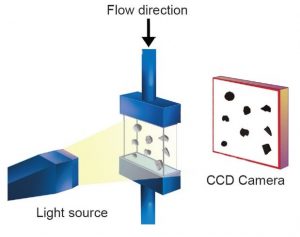

Dynamic Image Analysis (DIA) is a relatively new technique that is not sensitive to temperature nor is it sensitive to alignment issues. The temperature of the suspension fluid does not impact the analysis of particles. This makes DIA a perfect technique for a portable instrument that can be used in the most demanding environments.

In addition, it is the only technique for particle size and shape that will have the same level of resolution in the field as it does in the lab. This means that an operator can obtain high resolution particle size and shape data at the point of testing.

Dynamic Image Analysis technique is very simple. High resolution pictures of particles are taken and analyzed by software. Does not care about temperature or vibration.

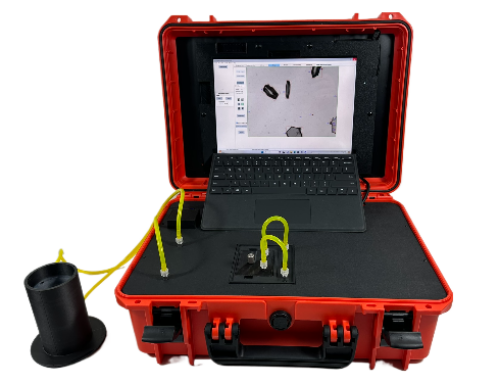

The Particle Insight Raptor Portable was designed for both benchtop and portable applications, the Raptor Portable ensures that precise particle analysis is no longer confined to the laboratory. Its ruggedized case and battery operation allow for seamless transitions between on-site and in-lab analyses, making it an invaluable tool for industries requiring flexibility without compromising on accuracy.

When working in the lab, simply connect an external keyboard, mouse, monitor, and network connection to the ports located on the side of the instrument. When you are ready to take field-based real-time analysis, simply close the case and take it with you to run your samples where your samples are. No more sending samples to the lab.

Designed for both benchtop and portable applications, the Raptor Portable ensures that precise particle analysis is no longer confined to the laboratory. Its ruggedized case and battery operation allow for seamless transitions between on-site and in-lab analyses, making it an invaluable tool for industries requiring flexibility without compromising on accuracy

More than just portable particle size.

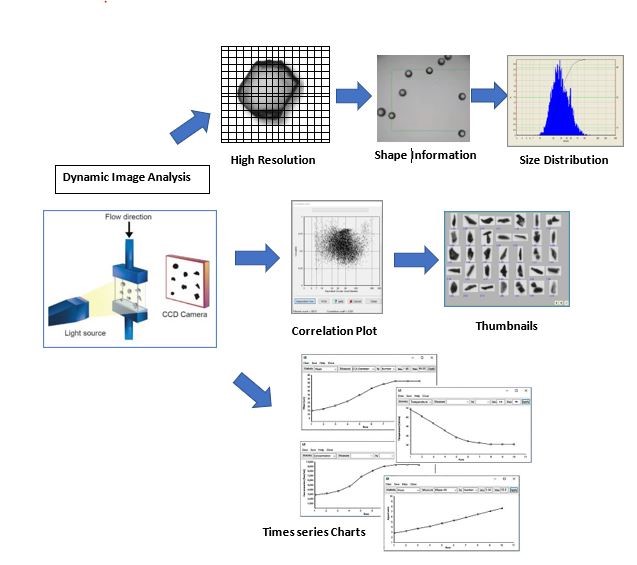

We’ve established that Dynamic Image Analysis is a technique that is ideal both as a portable and lab-based particle size and shape analyzer. However, Dynamic Image Analysis is also a technique that eliminates the need for an expert to interpret data.

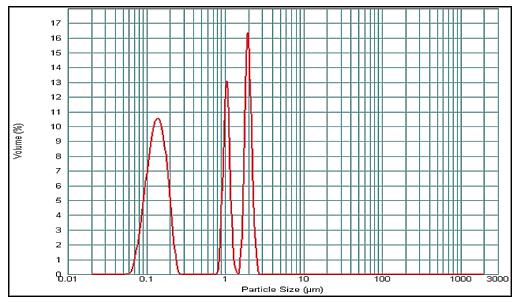

Traditional particle size results are reported in the form of a Volume-Weighted size histogram and an D10, D50 and D90 value to determine if a process is in or out of control.

Typical Size-Only results from Laser Diffraction systems require experts to read statistics and make a determination of what is going on in the process.

Dynamic Image Analysis workflow offers the information to customers enabling them to make a decision at the testing site without the need of an expert to identify a problem.

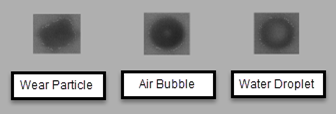

Dynamic Imaging, being a direct measurement method, reports particle size and shape. In addition, this technique also reports additional information including thumbnail images as evidence of particles measured.

-

Identify problems at the testing site: NO EXPERT REQUIRED to determine a problem in the field. This allows for immediate action by the operator. Easily identify agglomerates, contamination, air bubbles, water droplets, etc. No guessing.

-

Identify mixed samples: Many industrial samples are a mix of different particles or sizes. Dynamic Imaging makes 32 measurements of every particle allowing the software to automatically differentiate one particle population from another.

- Particle Counts: Being a number-based technique, the Raptor Portable Particle Size Analyzer can give you particle counts and concentration of the total sample or of a sub-population of particles.

- On-Line Continuous Process Monitoring: DIA and the Raptor Portable also supports real-time analysis, allowing for immediate adjustments and optimization of manufacturing processes. This means that the same system can be adapted for on-line continuous analysis.

Dynamic Imaging uses the shape of each particle to differentiate them.

Conclusion

High resolution data in the field, no expert required….

How would you feel if you could make a decision on your process in the field without sending samples to the lab?

The Particle Insight Raptor Portable stands at the forefront of particle analysis technology, combining portability with high-resolution measurement capabilities. Its advanced features and adaptability make it an essential instrument for industries aiming to achieve meticulous quality control and process optimization.

For more information on the Pi Raptor Portable, click here.

Learn more about the Particle Insight Raptor from some of our Channel Partners…

Meritics Limited – UK – Particle Insight Raptor Portable

🚀 The future of particle size and shape is here! Explore how Dynamic Imaging can transform the way you test materials.

📩 Contact us or visit www.ParticleShape.com to learn more about how DIA technology is setting a new standard for contamination monitoring.

📩 Want to run a free sample? Contact us or visit www.ParticleShape.com

🚀Other articles to view….