Introduction: Oil Cleanliness Testing Beyond the Numbers

In the fuel, lubrication, and hydraulic maintenance industries, particle contamination monitoring is critical. Reliability engineers and oil analysis labs depend on cleanliness codes such as ISO 4406 to assess wear, system health, and contamination risk.

But there’s one major limitation with traditional particle counting:

Most instruments report particle counts… without ever showing you the particles.

In this new demonstration video, I run real oil samples on the Raptor Portable Dynamic Image Analyzer, starting with hydraulic oil seeded with Medium Test Dust, and finishing with a challenging dark used machine oil sample.

The goal is simple:

-

Show exactly what contamination looks like

-

Demonstrate how easy oil particle testing can be

-

Provide full transparency into the process

📹 Watch the full video demo here:

Why Medium Test Dust Matters in ISO 4406 Testing

Medium Test Dust is one of the most widely used reference materials in the lubrication and hydraulic industries. It is commonly used to:

-

Validate particle counters

-

Check instrument performance

-

Support ISO cleanliness reporting workflows

Most labs are familiar with Medium Test Dust results from light obscuration particle counters, which have been the industry standard for decades.

But there’s an important question:

What does Medium Test Dust actually look like?

With traditional light obscuration methods, you never get to see the particles. You receive counts and code numbers — but not visual confirmation.

That’s where Dynamic Image Analysis (DIA) offers a major advantage.

Dynamic Image Analysis: Seeing Particles Instead of Assuming Them

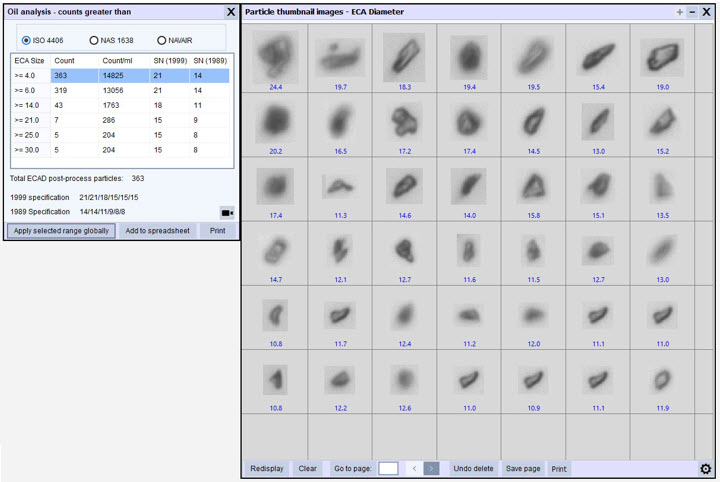

The Raptor Portable uses Dynamic Image Analysis, meaning it captures actual images of particles as they flow through the measurement zone.

Instead of relying only on light blockage signals, DIA provides:

-

Particle size distribution

-

Particle concentration

-

Shape and morphology information

-

Thumbnail images of real contamination

For reliability engineers, this is a powerful shift:

You don’t just get a cleanliness code — you get visual evidence.

Demo Part 1: Hydraulic Oil + Medium Test Dust

The first sample in the video is a controlled test:

-

Clean hydraulic oil

-

Seeded with Medium Test Dust

-

A common benchmark material for oil cleanliness instruments

Because Medium Test Dust is so widely used in ISO 4406 workflows, many professionals will immediately recognize the relevance of this test.

What makes this demo unique is that the Raptor Portable allows you to see:

-

What the dust particles look like

-

Their real shapes and sizes

-

How they appear under dynamic imaging

For anyone who has only worked with light obscuration systems, this is often the first time Medium Test Dust becomes “real” instead of abstract numbers.

Simple Workflow: Designed for Non-Experts

A key takeaway from the video is just how easy the process is.

The Raptor Portable workflow is straightforward:

-

Prepare the oil sample

-

Load it into the system

-

Run the measurement

-

Review results instantly in software

-

Examine particle thumbnails for deeper insight

No expert operator required.

This is especially important for:

-

Maintenance teams in industrial plants

-

Field technicians

-

Reliability engineers who need quick answers

-

Labs training new staff

Particle analysis should not require a PhD — it should be accessible, repeatable, and fast.

Demo Part 2: Running a Dark Used Machine Oil Sample

The final portion of the video addresses a real-world challenge:

Used oils are often too dark for traditional optical methods.

In this case, I take a dark used machine oil sample and dilute it with hydraulic fluid before running it on the Raptor system.

This demonstrates that even difficult samples can be handled with practical preparation techniques — making the system relevant not only for clean fluids, but also for:

-

Condition monitoring programs

-

Wear debris investigations

-

Contamination troubleshooting

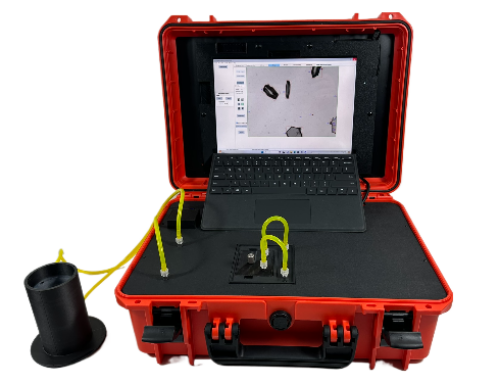

Portable System — Lab Proven, Field Ready

Although this demo was performed in the lab, the Raptor Portable is designed as a truly portable solution.

That means the same workflow can be applied:

-

At the maintenance bench

-

In a mobile oil analysis program

-

On-site in aerospace and defense operations

-

Directly in industrial reliability environments

Portability reduces turnaround time and enables faster decision-making.

Who Benefits Most from Particle Imaging in Oil?

This technology is especially valuable for:

Reliability Engineers

Identify contamination sources faster and improve predictive maintenance.

Oil Analysis Laboratories

Provide deeper reporting and particle morphology evidence beyond ISO codes.

Hydraulic Maintenance Teams

Quickly verify cleanliness levels without complex instrumentation.

Aerospace & Defense Applications

High-criticality systems demand both accuracy and transparency.

Final Thoughts: Oil Cleanliness with Visual Proof

Oil contamination monitoring is evolving.

The future is not just about particle counts — it’s about understanding what those particles are.

This demonstration highlights the key advantages of Dynamic Image Analysis:

-

Transparency

-

Ease of use

-

Visual evidence

-

Portable operation

-

Strong relevance to ISO 4406 workflows

If you’ve ever wondered what Medium Test Dust truly looks like — this video is worth watching.

📹 Full demonstration here:

(Embed YouTube Video)

Want to Learn More?

If you’d like a live walkthrough of the Raptor Portable or want to explore Dynamic Image Analysis for oil contamination monitoring, feel free to contact us.

👉 Learn more about the Raptor Portable here:

https://particleshape.com/particle-size-shape-count/

👉 Request a quote or demo here:

https://particleshape.com/contact/

CLICK here if you want to learn more about the Raptor Portable particle size and shape analyzer

CLICK here to learn more about Dynamic Image Analysis

CLICK here to learn why Particle shape is important