Add dynamic image analysis (DIA) to your existing Light Obscuration (LO) workflow to capture size, shape, and images of every subvisible particle.

-

Stand-alone or bolt-on imaging for your existing LO system

- Numerous sample suspension methods

-

Visual proof + morphology data for every particle

-

No workflow disruption / no full replacement

Why USP Introduced <1788.3>

Subvisible particle testing has long relied on Light Obscuration as the standard method defined in USP <787> and <788>. While effective for many applications, Light Obscuration primarily reports particle counts and size distributions, without providing confirmation of particle identity or structure.

USP <1788.3> was introduced to address this limitation by recognizing Dynamic Image Analysis (DIA) as an orthogonal method that adds particle images and morphology characterization to traditional results. This is particularly valuable for modern injectables and biologics, where particle populations may include soft or translucent materials such as protein aggregates and silicone oil droplets that can be difficult to detect or interpret using Light Obscuration alone.

By incorporating DIA, laboratories can strengthen their ability to:

-

confirm whether events are real or artifact

-

differentiate particle types

-

identify contamination sources faster

-

support deviations, investigations, and CAPA with visual evidence

USP <1788.3> represents the reality of modern injectables: the best practice is no longer “size and count only,” but size, count, shape, and images.

What USP <1788.3> Effectively Requires

To meet today’s expectations, manufacturers must be able to:

-

Confirm subvisible particles with visual evidence

-

Characterize morphology (shape, structure, and features)

-

Differentiate particle populations to support root-cause investigations

Why Light Obscuration Alone Falls Short

Light Obscuration remains the compendial standard for subvisible particle testing — but it was never designed to identify what particles actually are.

In modern injectables and biologics, many of the most critical particle populations are translucent, deformable, or irregular, including:

-

protein aggregates

-

silicone oil droplets

-

fibers and fragments

-

mixed particle populations that require differentiation

Because Light Obscuration reports only size and count, it provides no visual confirmation and limited insight into particle origin. This makes it difficult to determine whether an event is true contamination, an artifact, or a formulation-related issue — and it often leads to longer investigations and weaker supporting documentation.

When you can’t see the particles, you can’t confidently:

-

confirm the nature of a particulate event

-

differentiate particle types

-

identify root cause

-

support deviations and CAPA with defensible evidence

That’s why USP <1788.3> now emphasizes orthogonal characterization using Dynamic Image Analysis — so QC labs can move beyond “count-only” results and gain traceable, image-based confirmation for every detected particle.

The Bottom Line

Light Obscuration can tell you how many particles are present — but not what they are.

DIA provides the missing layer: size + shape + images for stronger investigations and defensible compliance.

The Raptor 1788 Solution: USP <1788.3> Imaging Without Replacement

You don’t need to replace your validated Light Obscuration system to meet USP <1788.3> expectations.

Instead, enhance it.

The Raptor 1788 besides being a stand-alone analyzer, integrates as a bolt-on Dynamic Image Analysis (DIA) module, adding the missing layer of compliance: particle images and morphology characterization — without disrupting existing SOPs or requiring a full instrument replacement.

With Raptor 1788, QC labs gain the ability to confirm, characterize, and differentiate subvisible particles while maintaining their established Light Obscuration workflow.

What Raptor 1788 Adds to Your Workflow

-

Images of every detected particle for traceable confirmation

-

Morphology metrics (shape, structure, transparency indicators)

-

Improved differentiation of particle populations (aggregates vs droplets vs fibers)

-

Stronger investigation support with visual evidence for deviations and CAPA

-

Faster root-cause analysis through morphology-based classification

How It Works as a Stand-Alone system

-

Load your sample.

-

Enter sample name & press Start

-

View results in the custom Dashboard

How It Works as an Add-On to your LO system

-

Run Light Obscuration as usual (USP <787>/<788>)

-

Add Raptor 1788 imaging (Connected inline) as an orthogonal characterization step

-

Confirm and classify particles using images + morphology data

Result: A compliance-ready approach that enhances existing methods instead of replacing them.

How Raptor 1788 Integrates Into Your Current Workflow

Raptor 1788 is designed to enhance your existing subvisible particle testing workflow — not replace it.

Most QC labs already rely on Light Obscuration for compendial reporting. Raptor 1788 adds Dynamic Image Analysis (DIA) as a complementary characterization step, providing the particle images and morphology data needed to support USP <1788.3> expectations.

A Simple 3-Step Approach

-

Run Light Obscuration as usual (USP <787>/<788>)

-

Analyze the same sample with Raptor 1788 for imaging and morphology

-

Confirm, characterize, and differentiate particles using traceable image evidence

This approach maintains your validated method while adding the missing layer of insight: size + count + shape + images.

Designed for QC Practicality

✅ Keep existing SOPs and reporting workflows

✅ Add orthogonal imaging only when needed

✅ Reduce validation burden vs full system replacement

✅ Accelerate investigations with image-based evidence

Key Benefits of Adding Raptor 1788

By integrating Dynamic Image Analysis into your subvisible particle program, Raptor 1788 helps QC labs move beyond “count-only” testing and gain the traceable evidence needed for modern injectable quality.

Fast Analysis Preserves Sample Integrity

Slow imaging methods can allow particles to settle, droplets to float and coalesce, and sample populations to drift during measurement. Raptor 1788 runs fast, helping preserve dispersion and deliver results that better reflect the true sample condition. Capable of running at speeds of as high as 200ml/min.

High Quality Visual Proof for Every Particle

Clearer particle images improve classification accuracy and confidence in investigations — especially when differentiating droplets, aggregates, fibers, and fragments. Better image quality strengthens traceability and supports more defensible quality decisions.

Differentiate Particle Populations

Distinguish common subvisible particle types — including protein aggregates, silicone oil droplets, fibers, and fragments — using morphology and image-based classification.

Reduce False Counts from Stuck Particles (Especially in Cell-Based Samples)

In some imaging systems, particles that adhere to the flow cell window can be repeatedly detected and counted across multiple frames. Raptor 1788 software includes tools to detect and ignore these stuck particles, improving accuracy and reducing false inflation of results.

Built-In Tools for Classification and Investigation

Raptor 1788 includes analysis tools that support particle classification, correlation plots, and deeper interpretation — helping QC teams move from detection to actionable insight without exporting data into multiple external tools.

Minimal Workflow Disruption

Raptor 1788 enhances your existing program while allowing QC teams to maintain established SOPs, compendial reporting practices, and production timelines.

The Result

A practical compliance-ready approach that adds size + shape + images — improving investigation quality while keeping your compendial workflow intact.

Does Raptor 1788 replace my Light Obscuration system?

No. Raptor 1788 is designed to enhance, not replace, your existing Light Obscuration system. Light Obscuration remains your compendial method (USP <787>/<788>), while Raptor 1788 adds orthogonal imaging and morphology characterization aligned with USP <1788.3>.

Will I need to revalidate my current Light Obscuration method?

In most cases, no. Because Raptor 1788 is added as an orthogonal characterization step, existing Light Obscuration methods and reporting workflows can remain unchanged. Validation requirements typically apply only to the added imaging workflow, not to the existing compendial method.

What particle size range does Raptor 1788 cover?

Raptor 1788 is optimized for subvisible particle analysis, 1-100 microns, supporting the particle size ranges described in USP <1788.3> for injectable products.

Can Raptor 1788 differentiate silicone oil droplets from protein aggregates?

Yes. By capturing particle images and morphology metrics, Raptor 1788 helps differentiate common subvisible particle types — including silicone oil droplets, protein aggregates, fibers, and fragments — which cannot be reliably distinguished using size and count data alone.

Why does image quality matter in subvisible particle investigations?

Image-based particle testing is only as useful as the images it generates. High-quality images improve classification confidence, reduce ambiguity, and strengthen traceability when supporting investigations, deviations, and CAPA documentation.

Does using Raptor 1788 slow down routine QC testing?

No. Raptor 1788 is typically used as a targeted characterization tool, applied when additional insight is needed — such as during investigations, deviations, or method development — without slowing routine Light Obscuration testing.

What happens if particles stick to the flow cell window?

In some imaging workflows, particles can adhere to the flow cell window and be repeatedly detected across multiple frames, artificially inflating particle counts. Raptor 1788 includes software tools to identify and ignore stuck particles, improving data integrity — especially in samples containing adherent cells or sticky contaminants.

Why does analysis speed matter for subvisible particle testing?

Subvisible particle samples can change quickly. Heavier contaminants may settle, while silicone oil droplets may float and coalesce, altering the particle population during long measurement times. Faster analysis helps preserve representative sampling, improve repeatability, and provide results that better reflect the original sample condition.

What analysis tools are available after the run is completed?

Raptor 1788 provides tools to support particle classification, correlation plots, and deeper investigation workflows. These outputs help teams interpret results faster and generate more defensible documentation without relying solely on basic counts and images.

Still have questions?

Our specialists can help you determine whether Raptor 1788 fits your current subvisible particle workflow and USP <1788.3> strategy.

Ready to Strengthen Your Subvisible Particle Program?

Add Dynamic Image Analysis to your existing Light Obscuration workflow and align with USP <1788.3> — without replacement, revalidation, or disruption.

👉 Request a Raptor 1788 Consultation

No obligation. No workflow disruption. Just a clearer path to compliant particle characterization.

Coming Soon: Raptor 1788 Integration with your existing Light Obscuration system

We’re taking compliance and performance even further. The Raptor 1788 will soon be available as a direct retrofit for your current Light Obscuration system, the industry required technique for USP <788>. This seamless integration brings Dynamic Image Analysis directly into your trusted workflow — no revalidation, no replacement, just enhanced insight.

Check back soon to see this powerful combination in action.

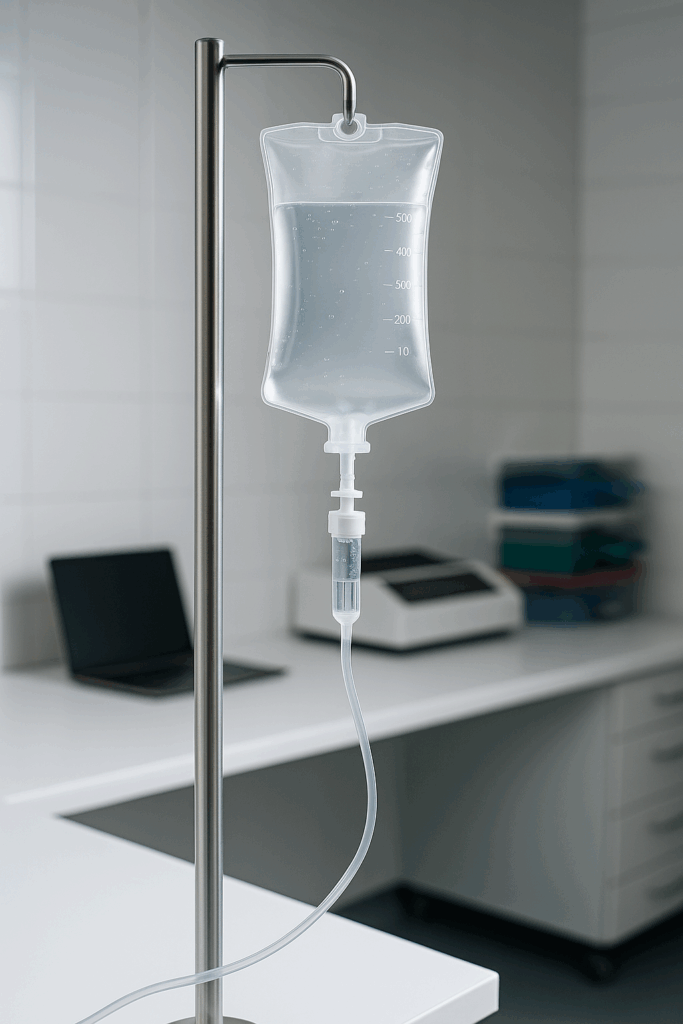

The Raptor 1788 will enable direct sample analysis from IV bags, eliminating the need to transfer samples into beakers or syringes. This non-invasive approach minimizes contamination risk, preserves sample integrity, and allows for long, continuous particle monitoring — something not possible with conventional Light Obscuration systems.

Stay tuned to see how the Raptor 1788 simplifies large-volume analysis while improving data accuracy and workflow efficiency.

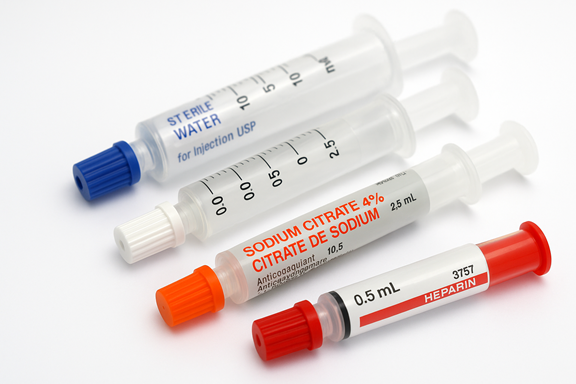

The Raptor 1788 will soon make it possible to analyze pre-filled syringes directly, eliminating the need to transfer samples into secondary containers. This approach preserves sample integrity, reduces contamination risk, and enables both particle and silicone droplet detection, identification, classification and concentration within the same test cycle.

By allowing analysis and return of the original sample, this method supports a true non-destructive workflow — ideal for high-value biologics and injectables where every drop counts.

Check back soon to see how Vision Analytical is redefining precision testing for pre-filled syringe applications.