One Eye Shut – Why Particle Sizing Evaluations Should Include Particle Shape, Dynamic Imaging Analysis

Focus on Powder Flow

Abstract

Why Particle Shape Matters in Powder Flowability

In pharmaceutical manufacturing, particle shape and size play a critical role in determining powder flowability, a property that directly impacts drug formulation, blending, and tablet compression. Traditional particle size analysis alone often provides an incomplete picture—ignoring the influence of shape on how powders behave under real processing conditions.

This white paper explores the importance of particle shape analysis in pharmaceutical applications, highlighting industry data that demonstrates the relationship between morphology and flow performance. By comparing results from complementary analytical techniques, we show how dynamic image analysis (DIA) offers a more complete understanding of powder behavior than particle sizing alone.

For pharmaceutical scientists and engineers, integrating particle shape characterization into quality control and research ensures improved consistency, safety, and regulatory compliance.

Disclaimer

The opinions, findings and conclusions expressed in this publication are those of the authors who are responsible for the facts and accuracy of the data presented herein. This report does not constitute a standard, specification or regulation. Authors reserve the right to modify and change this document at any time for the purposes of clarity and corrections.

1. Introduction

Particle size analysis has a broad range of applications encompassing virtually all industries. Numerous automated techniques exist for measuring particle size distribution and nearly all report particle size in units of equivalent spherical diameter which assumes the particles are all spherical or round in shape. This

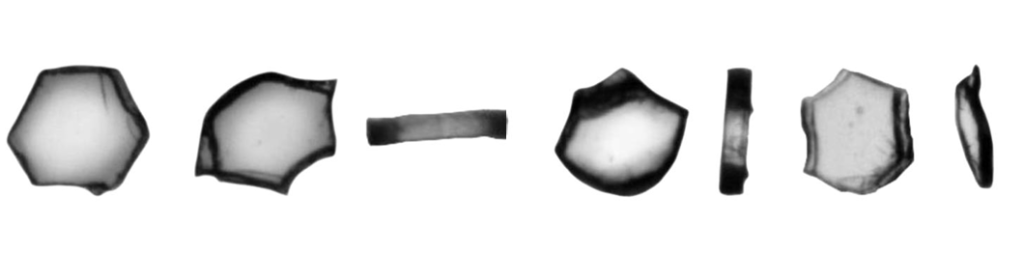

is necessary because of the ambiguity of describing the diameter of an irregularly shaped particle, and of constraints inherent in the instrument detection system. Of the available sizing instruments, Laser diffraction (LD) particle size analyzers are used extensively in many industries and within various applications. The LD method is a very robust, efficient, and reproducible method, but it does present significant shortcomings when particles deviate from spherical to more irregular shaped morphology. A needle shaped particle of 90 µm, may represent itself as having an equivalent sphere diameter of only a few microns in laser diffractions; based on its angular presentation to the LD detectors. Due to this phenomenon, as a particle deviates from spherical, the irregularity in circularity presented by that particle can have acute influence on the obtained Particle Size Distribution (PSD) of the population. This may result in the widening of that distribution, yet the actual size of the particles remains uniform and consistent. As an example, due to random orientation, a rod-like particle can present itself in Laser Diffraction as a rectangle, or as a circle representing the diameter of the rod, and of course, any possible combination of those orientations to the laser detection system.

Consideration of the effect of Particle Shape on Powder Flow It is well understood that Particle Size Distribution (PSD) is one of the most significant influences that affect the flow behavior of powders. Most operators have included robust particle-sizing analytical tools to access and control the Particle Size Distribution (PSD) to desired levels to ensure uninhibited flow character. But Particle Shape is also a key factor to determine and control powder flow and performance character. Particles segregate by their difference in mobility based on size, but it has been shown the shape also significantly influences that mobility. Shape controls the orientation and magnitude of the interparticle forces between particles. Particles of similar size but differing in shape can have very different flow behavior. Particles with irregular shaped surfaces can cause substantial mechanical interlocking and resistance to flow.

Surface irregularities or roughness can also influence flow behavior in fluidized bed reactors used for catalytic chemical reactions, the reaction kinetics are compromised as shape deviates from spherical to a flatten formed1. Irregularly shaped particles can minimize interparticle mass transfer rates. Catalyst deactivation rates increase with irregular or complex shaped particles showing increased carbon formation rates2.

In inhalation drug therapies, careful consideration of shape is recommended to complement particle size data. Shape has a direct impact on aerosolization, deposition and flowability. It has been shown that pollen shaped particles exhibited improved flowability, greater emitted dose, and improved higher fine particle fractions when compared to other shapes of the same or similar PSD3.

In inhalation drug therapies, careful consideration of shape is recommended to complement particle size data. Shape has a direct impact on aerosolization, deposition and flowability. It has been shown that pollen shaped particles exhibited improved flowability, greater emitted dose, and improved higher fine particle fractions when compared to other shapes of the same or similar PSD3.

In pharmaceuticals the control of shape, and crystal form is vital as they factor effect to downstream processing operations such as filtration, drying, and milling. Shape will also determine the physical and chemical properties of the API such as dissolution rate and solubility5.

In inhalation drug therapies, careful consideration of shape is recommended to complement particle size data. Shape has a direct impact on aerosolization, deposition and flowability. It has been shown that pollen shaped particles exhibited improved flowability, greater emitted dose, and improved higher fine particle fractions when compared to other shapes of the same or similar PSD3.

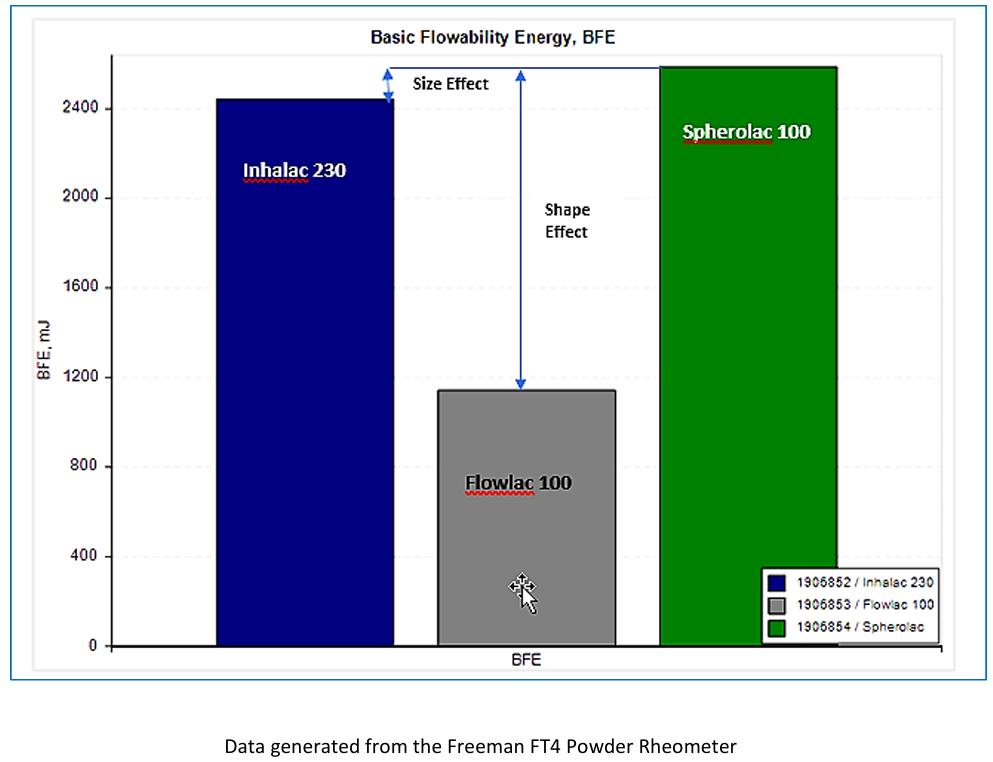

To illustrate the influence of shape in pharmaceutical excipients, we analyzed three commercial samples of lactose (FlowLac 100, SpheroLac 100 and Inhalac 230). Of these lactose samples, the FlowLac 100 and SpheroLac 100 have very similar Particle Size Distribution (PSD), but exhibit a difference in actual shape, whereas the Inhalac 230 and SpheroLac 100 have similar shapes but differ in PSD. In this case, it can be observed that the Basic Flowability Energy difference is most influenced by the difference in shape morphology of the samples tested as compared to the influence of Particle Size Distribution.

Integrating Dynamic Image Analysis into A Laser Diffraction Particle Sizing Workflow.

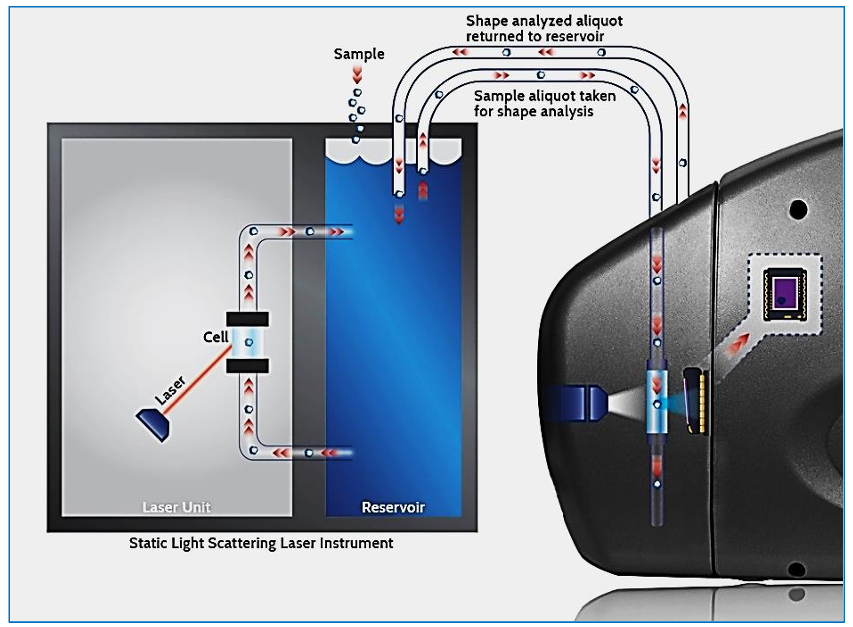

It is now possible to integrate a dynamic imaging shape analyzer directly in the workflow fluid path of your particle sizing laser diffraction instrument. The Particle Insight series instruments (Sentinel Pro, Hydro Insight, and Raptor) have the capability to be used as a complimentary method by connecting directly to the sample vessel or in-line fluidic path of the laser diffraction system. This ensures the same aliquot being tested on the laser diffraction system is the same sample being tested for shape. It requires no changes or re-validation of the current method or process, instead easily integrating within the fluid path of the existing size-only instrument. As the sample is being analyzed, the Particle Insight system taps into the sample reservoir of the sizing instrument, removes an aliquot of no more than 30 ml of the sample, performs real-time shape analysis and returns the sample to the existing instrument without jeopardizing sample or the integrity of the results for size obtained by the particle sizing instrument.

Dynamic Image Analysis uses high speed, high resolution optics to capture each individual particle as it is continuously streamed past the detection zone of known and controlled volume. This type of system permits random orientation so that each individual particle’s physical shape and size can be measured and represented as a gray scale image and as a binary fingerprint that is used for data deconvolution. By having a continuous flow, resulting in random orientation, dynamic imaging is not compromised with spatial orientation limitations as has been observed with Laser Diffraction (LD). It is also possible to determine particle concentration due to the high-speed particle capture rate and the known volume in the detection area.

Although Laser Diffraction is a powerful technique, it must be noted that there are several areas that may limit the reported Particle Size Distribution accuracy due to the architecture of Laser Diffraction and its following limitations:

- The limited angular resolution of the detectors employed

- Small surface irregularities can produce ghost peaks

- Orientation of non-spherical particles to the light source in the measurement cell

- The assumptions utilized by proprietary algorithms used for the deconvolution of the scattering data

- Theory based on particles only being spherical in nature

Incorporating Dynamic Image analysis and integrating it directly within the sizing workflow permits a user to capture important shape information as well as provide an orthogonal technique used to validate the sizing data. With this important addition to any particle morphology determinations in the laboratory, the user of this integrated workflow can now work with both eyes open when determining size and shape data of their particles.

For detail information on Dynamic Image Analysis, please contact us at www.ParticleShape.com

References

1 Cho, Jaehun & Sohn, Hong Yong. (2016). Effects of particle shape and size distribution on the overall fluid-solid reaction rates of particle assemblages. The Canadian Journal of Chemical Engineering. 94. 10.1002/cjce.22533.

2 Karthik G. M. and Vivek V. Buwa* Effect of Particle Shape on Catalyst Deactivation Using Particle Resolved CFD Simulations, ISCRE25, May2018

3 Meer Saiful Hassan, Raymond Wai Man Lau. Effect of Particle Shape on Dry Particle Inhalation: Study of Flowability, Aerosolization, and Deposition Properties AAPS PharmSciTech. 2009 Dec; 10(4): 1252. Published online 2009 Oct 29. doi: 10.1208/s12249-009-9313-

4 Hlosta, Jakub & Žurovec, David & Jezerská, Lucie & Zegzulka, Jiří & Necas, Jan. (2016). Effect of Particle Shape and Size on the compressibility and bulk properties of powder, Powder Mettalurgy June 2016

5 Jie Chen, Bipul Sarma, James M. B. Evans, and Allan S. Myerson, Pharmaceutical Crystallization, Crystal Growth & Design 2011 11 (4), 887-895 DOI: 10.1021/cg101556s