Why Particle Shape is important

For many years, particle size has been a vital characterization method. Most of the established techniques for particle size characterization are indirect measurement techniques that render particle size results assuming all the measured particles are round. Most particles in industry are not round, leaving significant doubt on the ability of size-only techniques to offer enough characterization information.

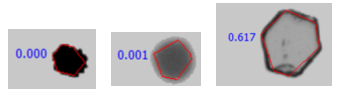

As an example, this abrasive particle, being represented as a round particle, would lead one to believe that this is a 100.1 µm particle.

- Size 100.1 µm

- Smoothness is 0.509

- Circularity is 0.321

- Bounding Rectangle Aspect Ratio is 2.36 where Width is 82 µm, Length is 193.2 µm.

Irregular particle shape can significantly impact how particles interact with each other, how they flow, and how they compact, ultimately impacting the efficacy of final products. Because of this, many years ago, scientists embraced and elevated the characterization of particles based on shape and size by using direct measurement techniques such as microscopes. Although slow and tedious, microscopy allows users to obtain qualitative information about their raw materials particles even though it is practical to measure only a small population of particles.

It wasn’t until the early 1990s when improved machine vision cameras and higher performing computers were around to start analyzing the shape of particles in a more standardized way with a much higher sampling of particles. Image Analysis, whether the particles are static or dynamically moving, involves very fast image processing.

Commercial shape analysis systems began to appear on the market in the 1990’s and 2000’s. Being a new technique, it was competing against well-established size-only instrumentation such as laser diffraction. As with any new technique, it took many years of education to let the industry realize that shape analysis systems existed. Approximately in 2014, new add-on shape analysis systems, such as the Particle Insight Shape Module, were developed to attach to existing size-only instruments as a shape complement. From this, shape analysis has become known as a complementary method to different size-only techniques. This technique’s high-resolution nature and flexibility have also enabled it to be incorporated into broad application areas such as online particle analysis.

What kind of information does Particle Shape give that I can’t get from my Particle Size analyzer already?

Particle size is a very established measurement for raw materials. As such, dynamic image analysis instrumentation will always give particle size as one of its shape measurements. This is done not only because particle size is very well established, but also because customers typically like to compare particle size information with their existing technique. For comparisons in particle size with different techniques, please view our overview document on different shapes with different techniques.

Dynamic image analysis is a number-based technique. This means that it measures particles individually. There are a few other techniques in the industry that are also number based and are very suitable to give individual particle information as well as count and concentration information which is very important to many industries. In addition, dynamic image analysis is a direct measurement technique. This means that measurements are being made of the actual particle. Because of this, dynamic image analysis is capable of reporting particle size not only in a typical volume-weighted distribution but also in a number-weighted distribution.

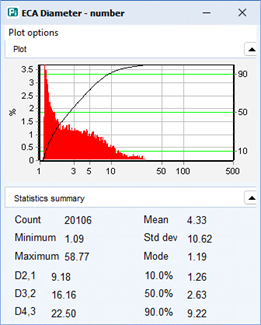

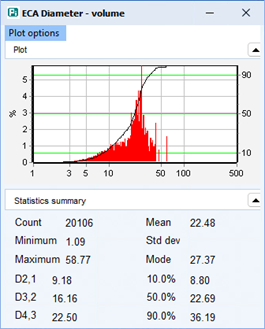

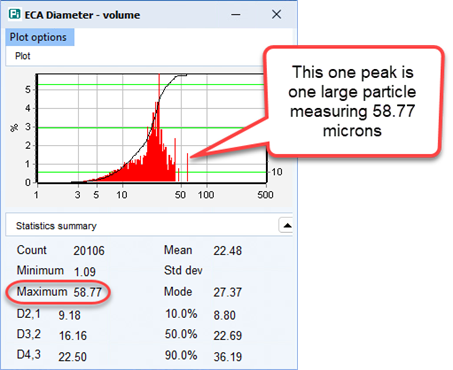

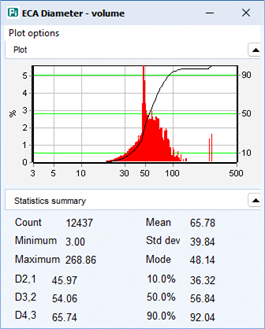

Above we show both a number-weighted distribution as well as a volume-weighted distribution of the same sample. Having accurate results of both are very important. For example, monitoring and controlling the amount of fine particles in the sample maybe important because it can impact improved flowability of larger particles, the clogging ohh filters, or find particle debris that can impact the process. Accurately viewing volume-weighted particle size information is also important in order to identify any agglomerates or large particles in your raw materials that can impact the final product.

Because dynamic image analysis is a number-based technique, every particle is represented on the histogram.

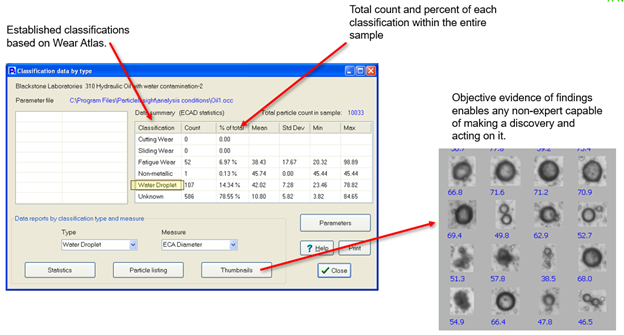

Many scientists and users today know how particle shape instrumentation can be used not only as a characterization but also as an identification tool. Regarding characterization, many use shape analysis to quantify the percentage of different particles in a mixed sample. For example, in the graph below, by only looking at this size histogram, an analyst would think that all their particles are in the 50-micron range with some odd peaks. When making determinations of your process using size-only information it typically requires an expert to view this graph and the statistics and decide what is going on in a process. When in fact, as can be seen here, this sample is made up of a series of three different shaped particles.

These three different shaped particles all have a size-only measurement of about 35 microns. This is if you’re looking at size-only data. As one can imagine, all these different shapes will blend, compact, flow, and behave differently in a process. This is why additional shape measurements are needed. To identify and quantify the different classes of particles.

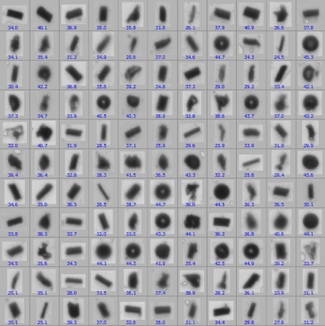

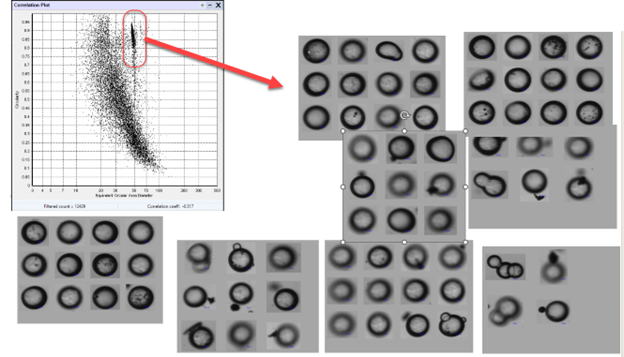

As is shown above, dynamic image analysis also gives the user thumbnail images of every measured particle. Besides making 30+ shape measurements of every particle to facilitate differentiating one from the other, the ability to see a thumbnail image as objective evidence eliminates the need for an expert to make a decision based only on a statistical graph and numerical data. In many instances differences in shape, not size, can be used to identify different lots of raw materials. Particle thumbnails help users to detect and identify large particles as either bubbles, agglomerates, or contamination.

Besides size, what other measurements of shape are made with dynamic image analysis?

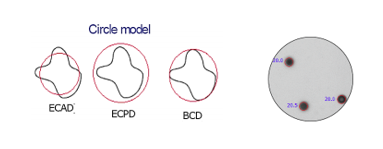

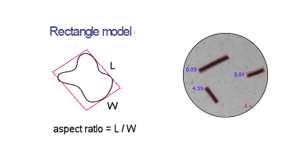

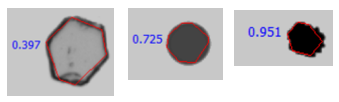

In the case of the Particle Insight line of products from Vision Analytical, there are a total of 30+ size and shape measures, within 6 different shape models, as well as the ability to correlate any two measures to find rare event particles. Normally not all shape models are going to be of use to a user. However, it is very common to have one or more be of importance. For example, for a rod-shaped particle, the length and the aspect ratio may both be equally important. Or in the case of an abrasive powder, the Circularity and the Smoothness is important to monitor. It is important to identify which set of the 6 shape models would best be suited to identify key performance measures for your particles.

For example, if your samples are a mixture of round and rod-like particles and they are separating or are not compacting well, then possibly the ratio of round (circular model) to long (length models) is important to monitor.

Particle Characterization Shape Models measures

Circle: equivalent area (Heywood) diameter, equivalent perimeter diameter, bounding circle diameter, circularity, form factor, compactness.

Ellipse: equivalent area diameter, bounding ellipse diameter, ellipticity.

Rectangle: bounding rectangle length, width, aspect ratio; rectangularity.

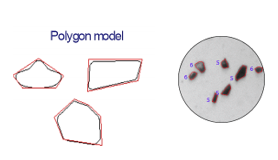

Polygon: polygon order, convexity, interior angles.

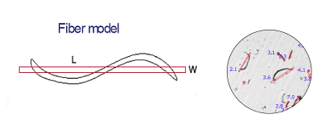

Fiber: length, width, aspect ratio, curl.

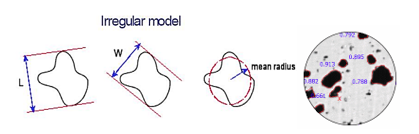

Irregular: Feret length, width, aspect ratio, mean radius, smoothness.

Pixel Intensity: Opacity and White Fraction.

Opacity: The particle’s intensity mean is calculated as a value 0 black) and 255 (white). Opacity is then computed as (256 – (Intensity Mean))/256.

0 is fully transparent, 1 is fully opaque.

White Fraction: White fraction is the fraction of the particle area that is lighter than Dark Threshold in Analysis Conditions options.

Why else would particle shape be of help to me?

Many scientists and users today know how particle shape instrumentation can be used not only as a characterization but also as an identification tool. Regarding characterization, many use shape analysis to quantify the percentage of different particles in a mixed sample. For example, a user can characterize the percent of excipient to active pharmaceutical ingredients after mixing. They can also then perform the exact measurements before tableting.

Shape analysis also allows for the identification of rare events. In some applications it is difficult to identify and quantify contamination particles or agglomerates. With the use of functional correlation plots a user can easily identify these particles of interest and have thumbnail images of them as objective evidence.

There are many other benefits to Particle shape analysis using dynamic image analysis techniques. In addition to giving particle size, identifying we are events, and classifying particles, Dynamic imaging analysis offers many more tools. Please see our log page on our website as well as our white papers and application notes for more practical use of dynamic image analysis to solve real world problems.

To view this article on Azo Network, Click Here.