The challenge

Abrasive Powders are used in a variety of everyday applications. It can be the particles used to polish teeth, abrasive polishes to make expensive automotive finishings shine, or even the sandpaper a carpenter uses for his daily work. All of these powders are designed to remove material. Some are more aggressive in removal than others. Sometimes the abrasiveness of particles is referred to as the “grit” of the powder. As you can imagine the more aggressive the grit, the more removal of material one would expect. However, the grit of the powder is a function of not only the size of the particles but also its shape characteristics. A low grit, which corresponds to a stronger removal, has larger particles. However if these larger particles were all smooth and round, the removal performance would be poor. Because of this, both size and smoothness are important in abrasive powders.

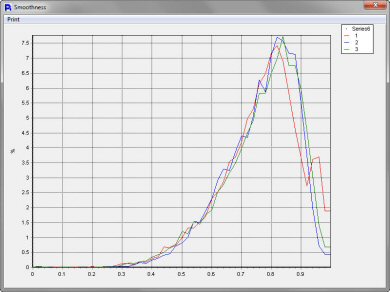

Here we study various abrasive powders and show how these powders contrast not only in size for the different grit classifications but also how they compare in smoothness. As we will see, proving abrasive consistency cannot be done by size alone. The Smoothness of the powders is also a critical measure to control.

Applicable measures |

Measure

|

Range of acceptance

3 – 500 microns |

Procedures and Results

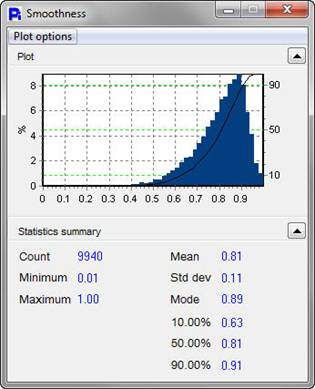

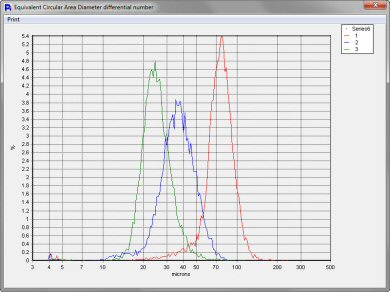

Several abrasive powder samples were analyzed. For this report we are using three different abrasive powders, each being a different “grit.” The manufacturer of these abrasive powders currently use a size-only measurement to check the quality of their abrasive powders before sending them to their final use: polish and in most cases, sandpapers for different applications. Particle-size-only instruments will report sizes as if the particles are round, and do not report shape information. That may be acceptable for some raw materials but where the smoothness of the particles is directly associated with their performance, this is not adequate.

The Particle Insight is able to analyze thousands of particles in just a few minutes and show results of up to 30 size and shape measures. For this study, the Particle Insight was able to do detailed statistical analysis of the smoothness of these particles as well as enable the user to see any single particle that may have been out of specification.

Particle images and data

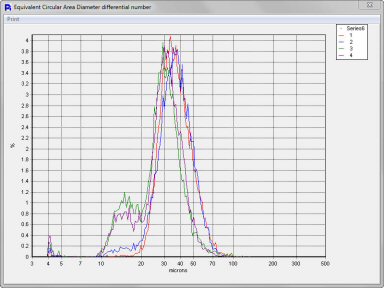

The Particle Insight allows correlating any two size/shape measures. Here we see a scatter chart of all these abrasive particles, plotted by Size and Smoothness. The correlation plot shows that size and smoothness are mostly independent of each other.

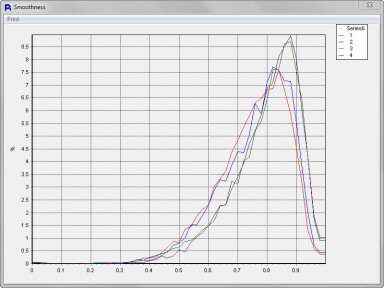

After analyzing three different grits of abrasive powders we can see that the particle size is different for all three, as we would expect. However, what we have shown here is that regardless of the size or grit of the abrasive powders, the smoothness of the powders are very uniform. This tells us that the grinding process of the manufacturer of these abrasive powders is very well under control. The consistency of the smoothness regardless of size is critical to ensure uniformity of performance of the abrasive particles regardless of their end use.

One other thing we were able to identify using the Particle Insight is that being a direct measurement technique that works on a counting or single-particle basis, if there are any large unwanted particles, we could easily identify those not only by the number based distribution and data for any single particle but also by viewing the thumbnails for each out-of-specification particle. After all, no one would want to polish their care with a product that has even one large unwanted particle.