The challenge

High Performance Liquid Chromatography is a separation technique used in analytical chemistry to separate, identify, and qualify various compounds in a solution. Most traditional analytical HPLC packing materials have an average diameter of approximately 2 to 30 microns. The particle size of the packing material is usually measured using methods that assume all particles are uniformly spherical. This may not be the case; fines and irregular shaped particles can be a percentage of the final product. As particle size decreases, the effect of fines and irregular shaped particles demands a greater degree of control on incoming quality of the silica material. Variation in particle shape can directly affect reproducible performance. What is needed is a way to quantify the fines and non-spherical particles.

Applicable measures

Measure

![]() Feret Width

Feret Width

![]() Feret Length

Feret Length

![]() Feret Aspect Ratio

Feret Aspect Ratio

Range of acceptance

3 – 100 microns

3 – 100 microns

1.0 – 30 .0

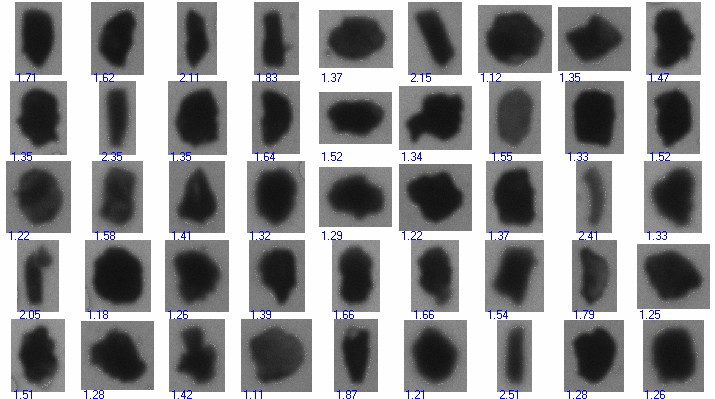

Typical thumbnail page

Random thumbnail images of the alumina sample from the 10,000 captured in just over one minute. The value under each thumbnail represents the Feret Aspect Ratio of the particle.

Procedures and Results

Proper sampling of the incoming materials was made to ensure a homogeneous sub-sample. The sample was then suspended in water and analyzed. After analysis and a review of all particle thumbnail images, it was evident that this alumina sample had two distinct shape populations. One was rod-shape and the other had an aspect ratio near unity, but the particles were not round. Had the sample been analyzed using a sizing technique that assumes all particles to be spherical, these rod-like and irregular particles would not be differentiated.

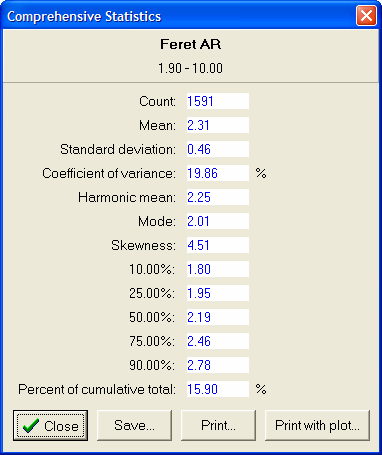

In developing a method for this sample, particles with an aspect ratio greater than 1.9 were considered to be rod-like and more likely to negatively impact the packing efficiency of the column. This aspect ratio value threshold was derived from sample lots that did and did not exhibit the problems previously described.

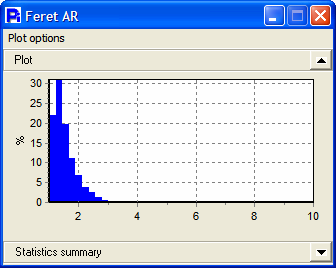

As shown in the histogram and statistical data, the percentage of rod-like particles in this column packing material was 15.90% of the total distribution which, compared to the historical lot of good material, proved to be excessive for the particular column application.

A review of the thumbnails for only those particles that have a Feret Aspect Ratio greater than 1.9 gives a better perspective on what these particles actually look like.

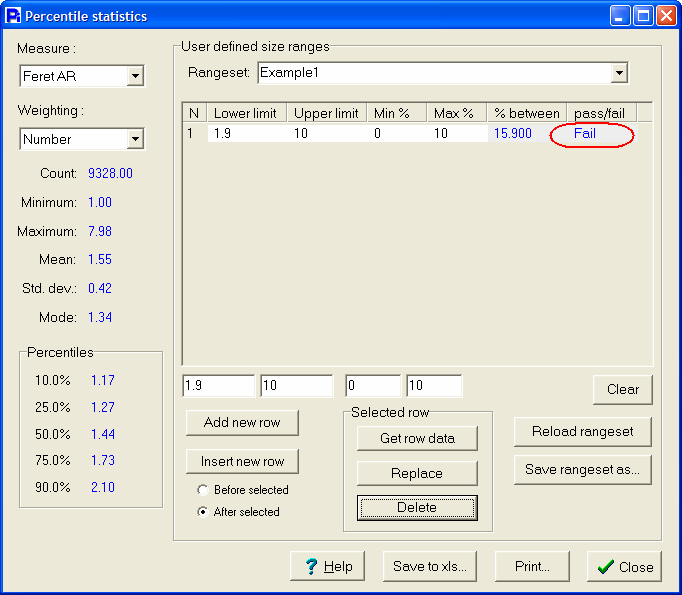

With a method established to determine that the Feret Aspect Ratio of incoming alumina packing material had no more than 10% rod-like particles, the end-user was able to create a simple process control indicator with the Particle Insight.

Using the Percentile Statistics feature, incoming quality control can determine easily and quickly if a lot of material passes or fails the criteria established by management.

Conclusions

The Particle Insight with its Dynamic Image Analysis technique can help reduce costs by finding HPLC packing material inconsistencies prior to reaching column manufacturing. The manufacturer is still responsible for determining the acceptable percentage of non-spherical particles for incoming materials. Once the manufacturer establishes incoming quality control criteria, the Particle Insight can be used as a pass/fail inspection tool to determine the percentage of spherical to non-spherical particles. Solving this potential problem early in the process improves production and helps to ensure consistent HPLC column quality and performance.