The challenge

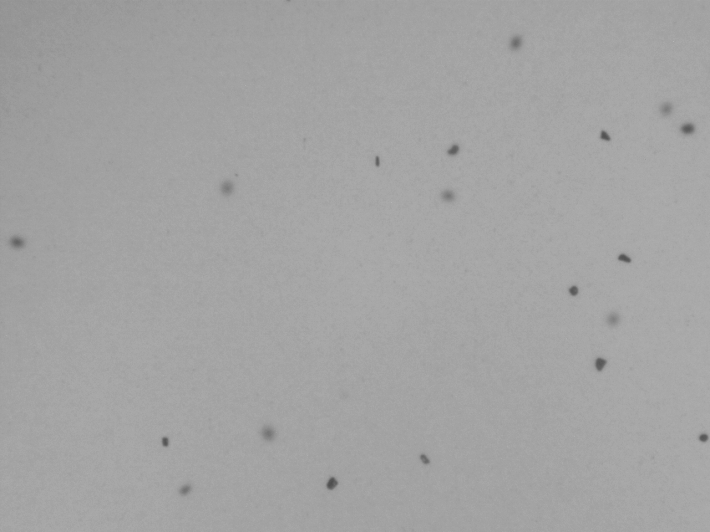

Finely-cut diamond abrasive is used to make industrial drills, grinding wheels and discs, dental tools and lapidary equipment. Grinding tools are used to shape steels, alloys, ceramics, glass, granite and other materials. Two sizes, or grits, of abrasive were studied. Below is a typical raw image of particles from each of the two samples.

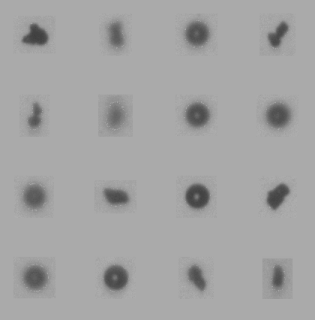

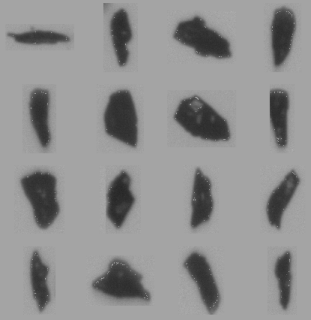

Here are two collections of particle thumbnails from the two samples:

|

|

| The first sample contains very fine sizes. There are also a few spherical bubbles present. They are between about 30 and 40 microns in diameter. | The second sample has considerably larger grains, with straight-faceted sides. Some of the sides are convex and some are concave. |

Size distribution is of primary interest; but since the abrasive grains are not round, a single size measure is inadequate. Length and width are needed. Particle shape also has a large effect on abrasive performance. A polygon shape with sharp angles performs best.

For size measurement, the elliptical model will work best. The particles are not ellipses; however a fitted ellipse can provide a good measure of width, length and aspect ratio. We will use the least bounding ellipse. For shape we use the polygon model since most particles appear polygonal with straight sides. Polygon order is the number of sides of the fitted polygon, and polygon angles are the interior angles of the polygon. Convexity tells us whether a particle has a generally convex shape, that is, how well it matches the fitted polygon. A particle with indented sides would have a lower convexity than one that fills most of the polygon.

Applicable measures |

Measure

|

Range of acceptance

3 – 500 microns |

Image analysis settings included minimum pixel area: 5; maximum pixel area: 50000; binary threshold: 80%; focus rejection parameter: 50; pump speed: 40%, and the option to correct size for diffraction effects is was enabled.

Results

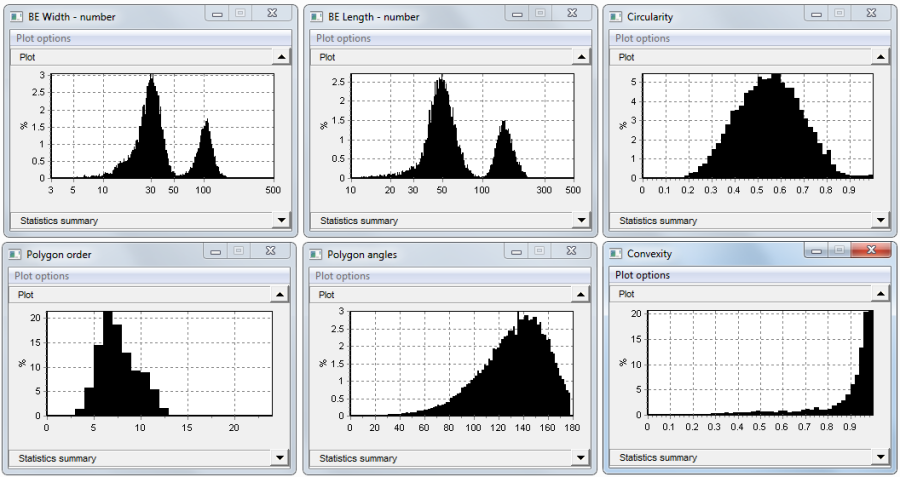

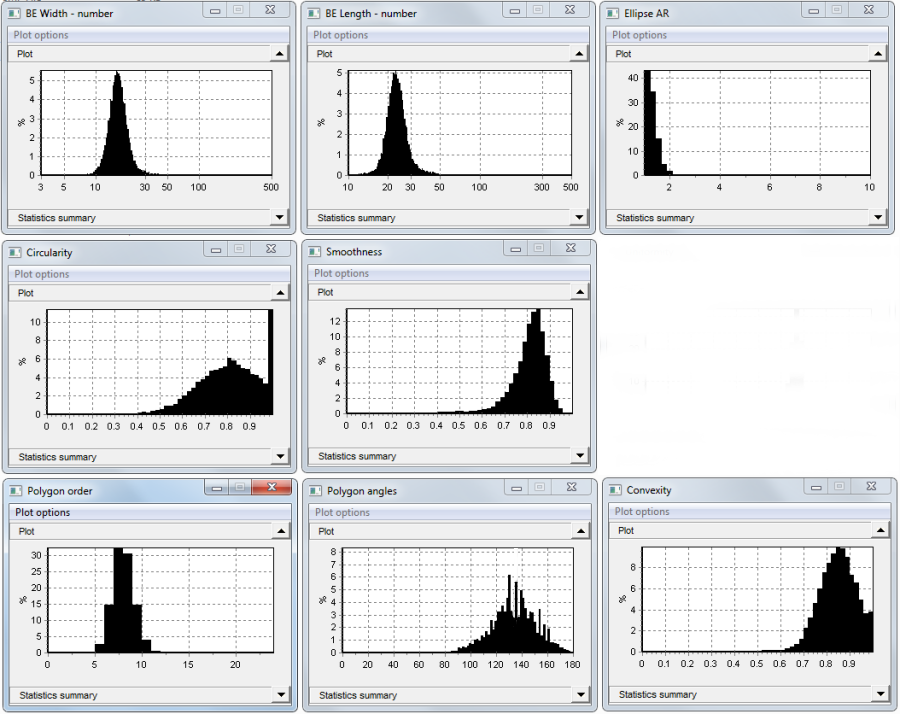

Sample 1:

Width and length are normally distributed, approximately, with all aspect ratios below about 2. Number of sides (polygon order) is centered around 7 and 8. Interior angles center around 135 degrees. Convexity has a spread to its distribution but is fairly high. Circularity shows a spike at 1 due to the presence of the spheres.

Using the post-processing filter, it is possible to reanalyze the particles excluding the spheres, by placing an upper limit of 0.99 on Circularity.

The data does not change much, because the spheres account for less than 10% of the sample (1430 out of 15114).

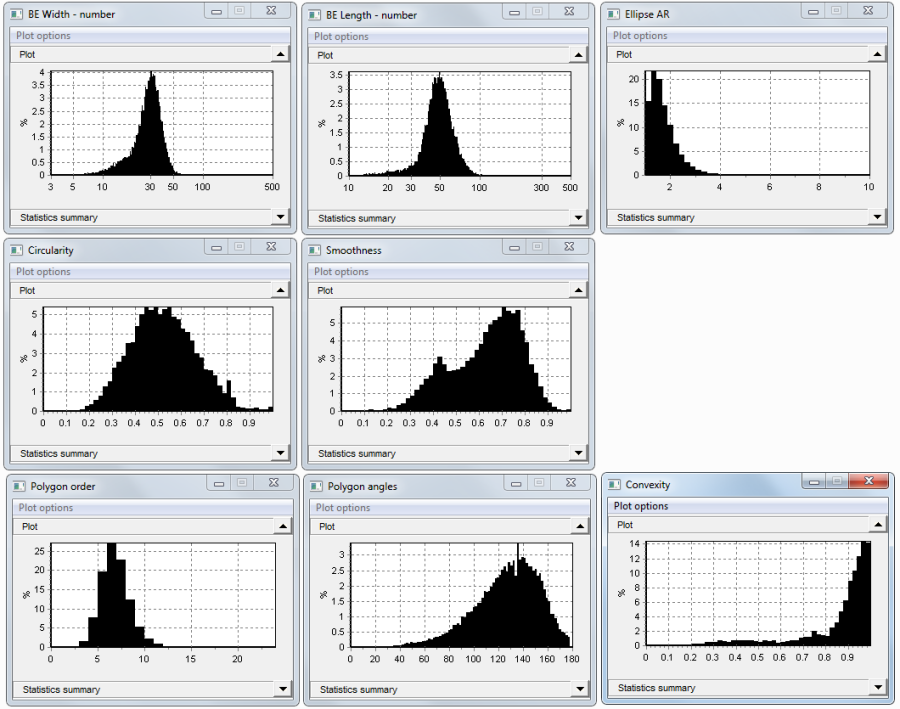

Sample 2:

In the second sample, the Bounding Ellipse width mean increased to 28.7 microns, from 17.0 in sample 1. Bounding Ellipse length increased from 23.9 to 49.4. Both Circularity and Smoothness of these larger abrasives are lower than the fines of sample 1. Polygon Order is about the same here. Interior angles have a similar mean, but the histogram now looks like the usual kind of skewed normal distribution. Many of the particles in sample 1 are too small to compute the angles. Convexity is higher with the larger abrasives.

A third sample was mixed from samples 1 and 2, for demonstration purposes. The analysis of that mixture shows the presence of the two original materials, in unequal amounts. It would be possible to separate out the two parts using one of the Particle Insight separation methods, and compare the results to the original samples.