The challenge

Toner powder for laser printers and photocopiers is a mix of carbon and a polymer. The specific polymer used varies by manufacturer. Toner formulations vary from manufacturer to manufacturer and even from machine to machine. Granule size is an important property that distinguishes the different formulations.

According to Wikipedia, “Originally, the particle size of toners averaged 14–16 micrometers or greater. To improve image resolution, particle size was reduced, eventually reaching about 8–10 micrometers for 600 dots per inch resolution. Toner manufacturers maintain a quality control standard for particle size distribution in order to produce a powder suitable for use in their printers.”

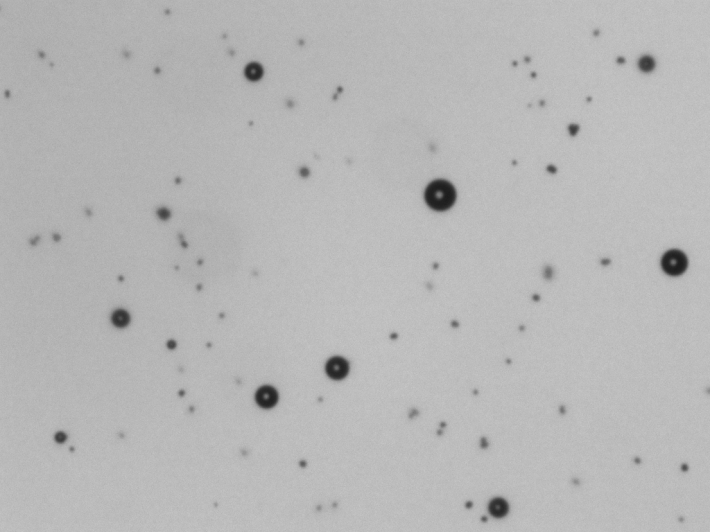

Toner grains are small and very close to spherical. There are also a few larger beads present. Because we can legitimately assume sphericity for everything, it is sufficient to use Equivalent Circular Area as the primary size measure, along with Circularity and Smoothness to provide additional characterization.

Applicable measures |

Measure

|

Range of acceptance

2 – 500 microns |

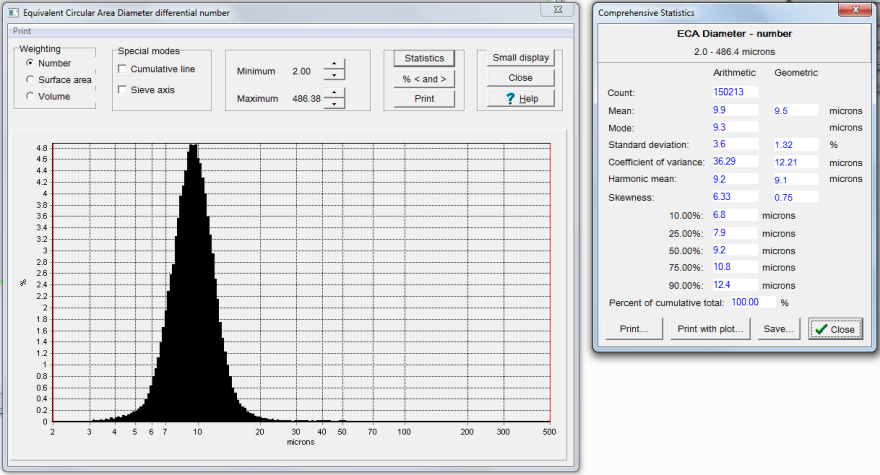

Image analysis settings included minimum pixel area: 5; maximum pixel area: 50000; binary threshold: 80%; focus rejection parameter: 50; pump speed: 40%, and the option to correct size for diffraction effects was enabled.

Results

A particle count of 150,000 produces very smooth distribution graphs. The ECA histogram is seen to be close to normal, with low skewness. the smallest size measured was 2 microns and the center is about 10 microns.

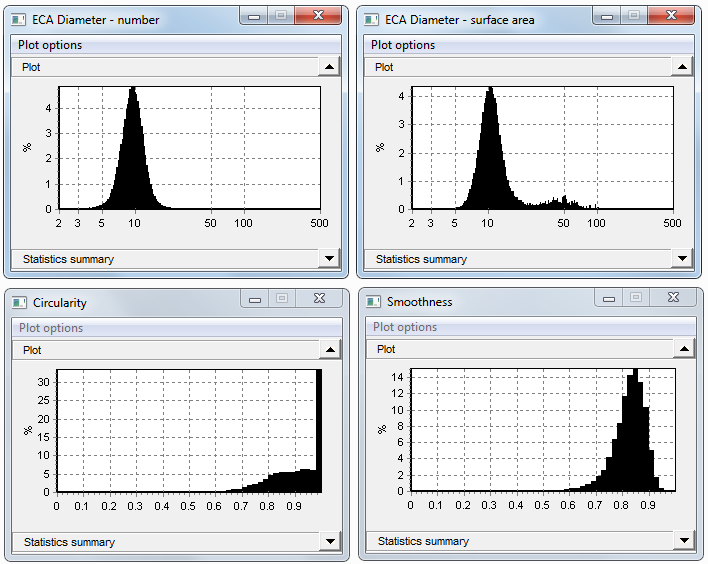

Below are seen the “small data window” plots for ECA (number and surface area), Circularity, and Smoothness. The large beads are too few in number compared to the toner grains to show up in the unweighted distribution, but they can be seen in the surface area-weighted plot because they contribute a noticeable amount to the total surface area. The spike in Circularity at 1 reflects the large beads and most of the small grains.