Knowledge Center

Welcome to our Knowledge Center. Here our goal is to offer the user an easy way to navigate to all of our educational content.

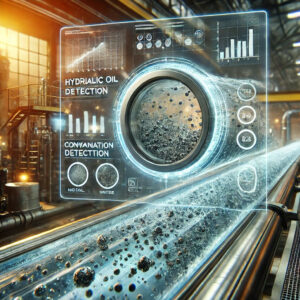

Hydraulic Oil Testing: Best Practices & ISO Standards for Contamination Control

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Revolutionizing Fluid Contamination Monitoring with Dynamic Image Analysis and ISO 21018-1

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Water Quality Particulate Testing with a VIEW

Unlike traditional particle counting, which only provides information on particle size, dynamic image analysis provides detailed data on both particle size and shape. This allows for better identification of specific types of particles (e.g., fibrous, spherical, irregular), which can help in distinguishing between organic matter, sediment, or chemical precipitates.

Sodium Ion Battery Powders – Shape really matters…

Particle shape plays a critical role in the performance and manufacturing of sodium-based batteries, particularly when it comes to the powders used for electrodes. The shape of the particles impacts several key factors that influence the efficiency, safety, and durability of the battery.

Fuel and Lubrication ASTM D7596-14 Particle Test Method for Shape Classification of Oils

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Particle Size and Shape of Petroleum Lost Circulation Material – #1

Lost Circulation Material (LCM) is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

Fluid loss prevention and particle shape analysis

More videos on different Lost Circulation Material (LCM) which is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

American Association of Drilling Engineers (AADE 24 FTCE) presentation

American Association of Drilling Engineers (AADE 24 FTCE) presentation

Particle Insight iPad Frequently-asked Questions

How do I get the Particle Insight iPad app? The Particle Insight iPad app can be purchased at the Apple App Store and installed from there. How does the Particle Insight iPad App work? Upon installation, the user can view particle shape and size data that was generated by a Particle Insight particle shape analyzer. [...]

APPLICATION EXAMPLE: Oil Contaminants (continued)

Particle Classification is one of the Particle Insight’s most useful features. It is part of the post-run processing operations that are available after a run is finished. You first define a group of classifications by imposing limits on the measures that have been selected for the run, or, use a saved parameter file. Although the Wear [...]

Individual particle listing

This post-processing feature creates a text or XLS file containing measure data for each and every particle in the sample database.

Percent Between

When the size distribution of a material must adhere to close specifications, one way to test that adherence is to divide the size axis into a few subranges and place limits on the allowable cumulative percent in each size subrange. In the example below, we have defined seven subranges and specified the allowable limits on [...]

Individual particle thumbnail images

Sometimes, in addition to statistical results, you need to be able to see what certain classes of particles actually look like. An option in the Particle Insight lets you record individual thumbnails for every particle during a run. As a post-process operation you can request a visual compilation of these thumbnails, ordered according to size. [...]

Post-process reanalysis

Post-process reanalysis can generate new statistical results after placing new restrictions on any desired measure or measures, that act in addition to the original limits that were in effect during the run. This is ECA data from a demonstration sample that contains powder plus monosized beads. To demonstrate how to filter out the monosize beads [...]

Particle Insight Raptor Portable Series

- Raptor – General Brochure

- Raptor – Fuel and Lubrication Edition

- Raptor – ASTM 7596-14 Compliance Document

- Raptor – Oil and Gas Edition

Hydro Insight Series

Particle Insight Sentinel Series

If you are looking for any specific document or information that you cannot find, please contact us and we will be able to answer your questions or even create any needed documentation.