The behavior of raw materials can typically be predicted by properly studying a sample and identifying physical characteristics such as particle size. Features most commonly analyzed include distribution, size, and shape. Particle size measurement is a crucial process in various industries, as understanding specific particles and their properties can enhance productivity, reduce waste and ensure product quality. This blog post will examine how commonly used particle shapes, rods and spheres, are properly analyzed for size and shape.

Why use Rod and Sphere Analysis in this example?

Most particle size measurement techniques are indirect, resulting in size-only results that assume all particles are round or spherical. Real-world samples are not always round. Most raw material samples tend to be irregular in shape. Therefore, using a measurement technique that assumes all particles are round may result in inaccurate assumptions. It would be the equivalent of forcing a square peg in a round hole to measure irregular particles, such as a mix of rods and spheres, and reporting results as if they are all round. Dynamic Image Analysis is the ideal tool for the measurement of irregular particles. A mix of rods and spherical particles is a perfect example of how Image Analysis can adequately measure and differentiate the two sample populations.

The Challenges of Irregular Particle Analysis

When results from size-only measurement techniques are produced, they can be misrepresentative due to biases. When spheres and fiber particles are both present in a sample, they are not accurately displayed on particle size statistical results. To compensate for these inaccuracies, Vision Analytical has manufactured an image analyzer that accurately represents samples, including differentiating between fibers and spheres. We provide more information below.

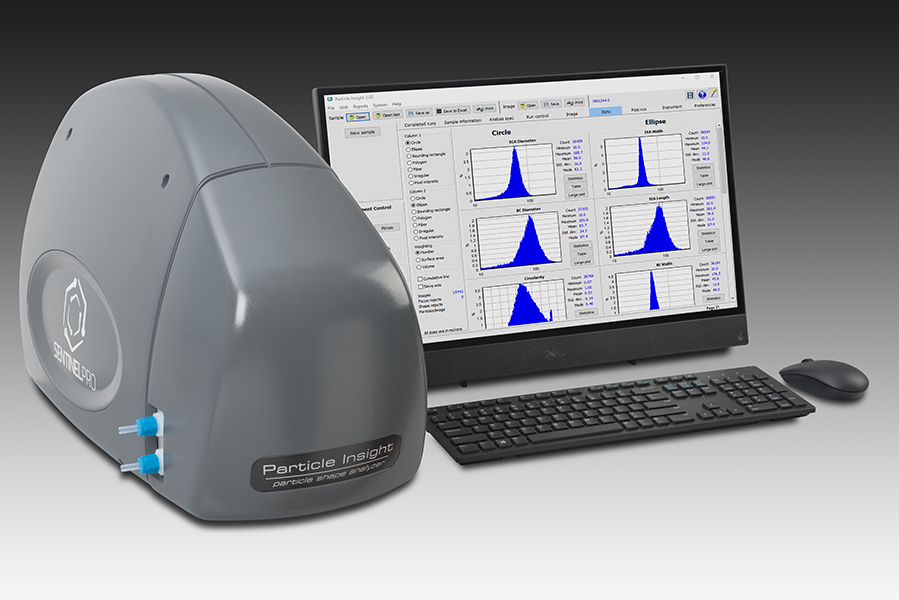

Vision Analytical and Particle Size & Shape Measurement

Vision Analytical’s series of Image Analysis equipment is the ideal solution and complement to size-only particle measurement techniques. In terms of sample analysis, it enables fiber-only analysis and fiber-sphere mix analysis, in which a separate peak clearly represents spheres. There are many benefits of the Insight systems, but one of the primary features is the ability to study various characteristics of individual particles. These characteristics include circularity, smoothness, aspect ratio, and over 32 other shape parameters.

Read More: Rods and Sphere Analysis for Shape and Particle Size

To support your particle shape measurement needs, the Particle Insight systems are designed with a high-speed digital camera to analyze samples in real time. Any analyzed particle will be issued a thumbnail image, and the instrument can compare different analyses via overlays.

Contact us today if your particle shape analysis processes would benefit from the Particle Insight series of instruments.