Knowledge Center

Welcome to our Knowledge Center. Here our goal is to offer the user an easy way to navigate to all of our educational content.

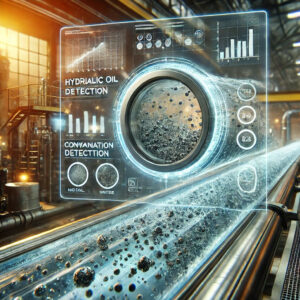

Hydraulic Oil Testing: Best Practices & ISO Standards for Contamination Control

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Revolutionizing Fluid Contamination Monitoring with Dynamic Image Analysis and ISO 21018-1

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Water Quality Particulate Testing with a VIEW

Unlike traditional particle counting, which only provides information on particle size, dynamic image analysis provides detailed data on both particle size and shape. This allows for better identification of specific types of particles (e.g., fibrous, spherical, irregular), which can help in distinguishing between organic matter, sediment, or chemical precipitates.

Sodium Ion Battery Powders – Shape really matters…

Particle shape plays a critical role in the performance and manufacturing of sodium-based batteries, particularly when it comes to the powders used for electrodes. The shape of the particles impacts several key factors that influence the efficiency, safety, and durability of the battery.

Fuel and Lubrication ASTM D7596-14 Particle Test Method for Shape Classification of Oils

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Particle Size and Shape of Petroleum Lost Circulation Material – #1

Lost Circulation Material (LCM) is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

Fluid loss prevention and particle shape analysis

More videos on different Lost Circulation Material (LCM) which is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

American Association of Drilling Engineers (AADE 24 FTCE) presentation

American Association of Drilling Engineers (AADE 24 FTCE) presentation

Significance

The Significance of Particle Shape Investigating raw materials for particle size distribution is a very common practice in many industries. Particle size measures have become the standard inspection criteria for incoming materials, and outgoing products that we all use every day. Particle size is the main way powders and other granular materials are quantized. But, [...]

Particle Characterization

Basics of Particle Characterization Size and shape are the attributes that most affect the behavior of particulate substances. Spherical beads are easily characterized by a single size measure – diameter. More irregular shapes are more difficult to characterize, but for powders used in manufacturing it is necessary to find a small set of numbers that [...]

Specifications

Specifications System: System type: imaging; images are analyzed in real time as they are captured. Particle size range: Diameter measures: 2 to 400 microns Width measures: 5 to 100 microns Length measures: 5 to 1000 microns Sample run time (25,000 particles): 100 seconds, typical Images per run: 200 to 400, typical Computer: Minimum system requirements: [...]

Custom Engineering

Instrument installations sometimes require customization to adapt to the needs of user’s processes. Typical requests include adapting our Particle Insight to an on-line process, or to develop custom sample cells needed for specific applications, or new software features to meet the needs of users and market needs. In some cases, these custom engineering projects become [...]

PARTICLE SHAPE APPLICATION EXAMPLE: Ocean Sediments

The challenge Ocean floor sediments are studied by marine scientists. They are composed of fine particles of sand, clay, volcanic ash, minerals and organics. The small grain size makes measurement a challenge. Two different kinds of sediment were studied for this example. Applicable measures Measure Equivalent Circular Area Diameter Equivalent Elliptical Area Width Equivalent Elliptical [...]

PARTICLE SHAPE APPLICATION EXAMPLE: Portland Cement

The challenge Portland cement is a controlled chemical combination of calcium, silicon, aluminum, iron and small amounts of other ingredients to which gypsum is added in the final grinding process to regulate the setting time. Lime and silica make up about 85% of the mass. Common among the materials used in its manufacture are limestone, [...]

Particle Insight Raptor Portable Series

- Raptor – General Brochure

- Raptor – Fuel and Lubrication Edition

- Raptor – ASTM 7596-14 Compliance Document

- Raptor – Oil and Gas Edition

Hydro Insight Series

Particle Insight Sentinel Series

If you are looking for any specific document or information that you cannot find, please contact us and we will be able to answer your questions or even create any needed documentation.