Knowledge Center

Welcome to our Knowledge Center. Here our goal is to offer the user an easy way to navigate to all of our educational content.

Sieve Correlation Using Dynamic Image Analysis

Sieve correlation has been a well-established method in particle sizing for many years, but the development of automated dynamic image analysis is beginning to revolutionize the process. In this blog post, we will discuss how automated dynamic image analysis is becoming a complementary method to sieve correlation and how it provides more accurate and detailed results.

Is Dynamic Image Analysis Essential for Proper Fiber Particle Analysis?

Dynamic image analysis (DIA) is a digital method of particle characterization that enables a researcher to identify the shape, size, and number of particles in a sample. Due to its high accuracy and reproducibility, DIA is a widely used image analysis method across most industries to support quality control, compliance, and research applications.

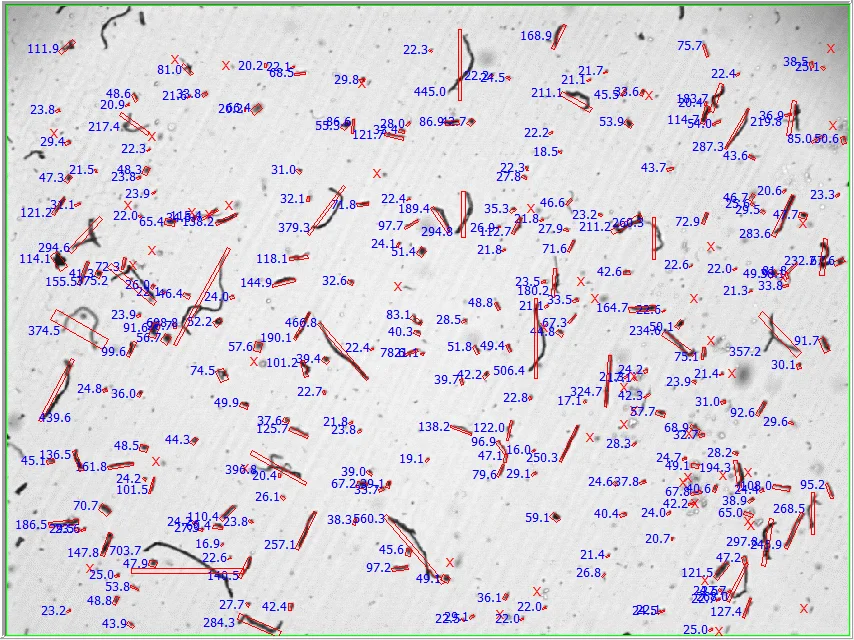

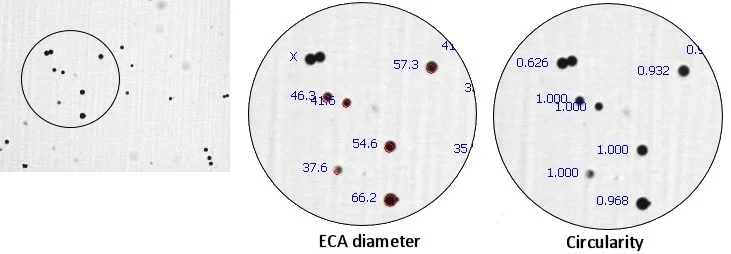

Shape Matters: The Importance of Image Analysis for Measurement of Rods and Spherical Particles

The behavior of raw materials can typically be predicted by properly studying a sample and identifying physical characteristics such as particle size. Features most commonly analyzed include distribution, size, and shape. Particle size measurement is a crucial process in various industries, as understanding specific particles and their properties can enhance productivity, reduce waste and ensure product quality.

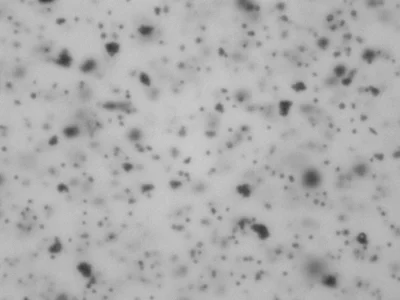

How & Why You Should Use Dynamic Imaging to Identify Agglomerates

Particle size is a crucial property to measure when dealing with particulate raw materials. It underlies key manufacturing parameters like flowability, packing, and wetting–each of which can have a demonstrable impact on the end quality of a part or product.

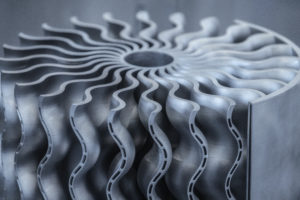

How Dynamic Image Analysis Helps Screen Metal Powders for 3D Printing

Creating parts using metal powders requires exceptional high-quality raw materials. Many analytical tools are used to pre-screen metal powders to ensure proper powder flowability, prevent clogging, and ensure adequate particle deposition to guarantee well-made parts.

How Particle Shape Analysis Compliments Size Measurements

Particle size reduction is a routine method of increasing surface area and making downstream processing more efficient. It is well documented that particle size distribution (PSD) affects powder flowability. However, studies have demonstrated the limitations of particle size analysis – particularly in applications with irregular particles. Ignoring particle shape can lead to significant under-estimation of the mean particle size which leads to errors in PSD results.

How Particle Shape Analysis Complements Abrasives

Particle size is a critical factor in qualifying abrasive powders. Larger particles typically produce an aggressive cutting action with fast material removal rates, albeit with a poor surface finish. Smaller particles, by contrast, offer a smoother finish with significantly reduced rates of removal.

Using Dynamic Image Analysis & Laser Diffraction for 3D Printing Metal Powder Identification

Material identification is a crucial part of the additive manufacturing process, particularly when dealing with metal powder feedstocks. Although metal powder 3D printing is increasingly common, there are various quality assurance and control (QA/QC) challenges that must be considered.

Particle Insight Raptor Portable Series

- Raptor – General Brochure

- Raptor – Fuel and Lubrication Edition

- Raptor – ASTM 7596-14 Compliance Document

- Raptor – Oil and Gas Edition

Hydro Insight Series

Particle Insight Sentinel Series

If you are looking for any specific document or information that you cannot find, please contact us and we will be able to answer your questions or even create any needed documentation.