Knowledge Center

Welcome to our Knowledge Center. Here our goal is to offer the user an easy way to navigate to all of our educational content.

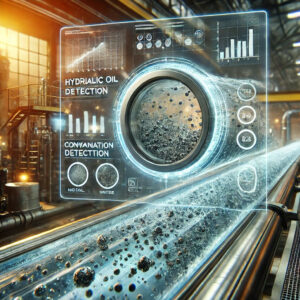

Hydraulic Oil Testing: Best Practices & ISO Standards for Contamination Control

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Revolutionizing Fluid Contamination Monitoring with Dynamic Image Analysis and ISO 21018-1

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Water Quality Particulate Testing with a VIEW

Unlike traditional particle counting, which only provides information on particle size, dynamic image analysis provides detailed data on both particle size and shape. This allows for better identification of specific types of particles (e.g., fibrous, spherical, irregular), which can help in distinguishing between organic matter, sediment, or chemical precipitates.

Sodium Ion Battery Powders – Shape really matters…

Particle shape plays a critical role in the performance and manufacturing of sodium-based batteries, particularly when it comes to the powders used for electrodes. The shape of the particles impacts several key factors that influence the efficiency, safety, and durability of the battery.

Fuel and Lubrication ASTM D7596-14 Particle Test Method for Shape Classification of Oils

The ASTM D7596-14 (ASTM, 2018) was designed as a guide for the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in service oils used for lubrication and hydraulic systems using a direct imaging integrated tester.

Particle Size and Shape of Petroleum Lost Circulation Material – #1

Lost Circulation Material (LCM) is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

Fluid loss prevention and particle shape analysis

More videos on different Lost Circulation Material (LCM) which is an additive introduced to drilling fluid that can come in all different shapes and sizes. It is well understood that irregular particles have greater thickening and strength properties. As a result, analyzing size alone for selection of LCM materials would not be ideal. In this case, shape measurements such as Circularity and Smoothness as well as size, are key measurement parameters to monitor.

American Association of Drilling Engineers (AADE 24 FTCE) presentation

American Association of Drilling Engineers (AADE 24 FTCE) presentation

PARTICLE SHAPE APPLICATION EXAMPLE: Pollen

The challenge There are many different varieties of pollen within various species. Several varieties of pollen were analyzed using Dynamic Image Analysis to test if their morphology (shape characteristics) could be used as a differentiator among the various types, and to differentiate between whole pollen grains and pieces or debris. Size-only methods often cannot make [...]

PARTICLE SHAPE APPLICATION EXAMPLE: Diamond Abrasives

The challenge Finely-cut diamond abrasive is used to make industrial drills, grinding wheels and discs, dental tools and lapidary equipment. Grinding tools are used to shape steels, alloys, ceramics, glass, granite and other materials. Two sizes, or grits, of abrasive were studied. Below is a typical raw image of particles from each of the two [...]

PARTICLE SHAPE APPLICATION EXAMPLE: Abrasives

The challenge Abrasive Powders are used in a variety of everyday applications. It can be the particles used to polish teeth, abrasive polishes to make expensive automotive finishings shine, or even the sandpaper a carpenter uses for his daily work. All of these powders are designed to remove material. Some are more aggressive in removal [...]

PARTICLE SHAPE APPLICATION EXAMPLE: Oil Contaminants

The challenge Early detection of wear particles in lubricating and hydraulic fluids is critical to having a proper predictive maintenance program. It is this early detection and identification of wear particles that permits the extension of engine life and can minimize down-time of equipment. The challenge is to count the number of contaminant particles between [...]

Separating Subcomponents of a Sample

Some of the examples in the Software section used artificially-prepared mixes of spheres and another kind of particle, for the sake of obviousness. Here we will look at a real-world sample that consists of two classes of particles. In the typical raw image shown below, there are small round particles together with larger, more irregular [...]

Particle Insight Raptor Portable Series

- Raptor – General Brochure

- Raptor – Fuel and Lubrication Edition

- Raptor – ASTM 7596-14 Compliance Document

- Raptor – Oil and Gas Edition

Hydro Insight Series

Particle Insight Sentinel Series

If you are looking for any specific document or information that you cannot find, please contact us and we will be able to answer your questions or even create any needed documentation.